Paint composition, anti-foul easy-cleaning product and preparation method thereof

A composition and coating technology, applied in the field of aluminum-plastic panels, anti-fouling and easy-to-clean products, can solve the problems of getting dirty, affecting the decorative appearance effect, etc., so as to prolong the cleaning cycle, improve the easy-to-clean function, and reduce the cleaning and maintenance cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

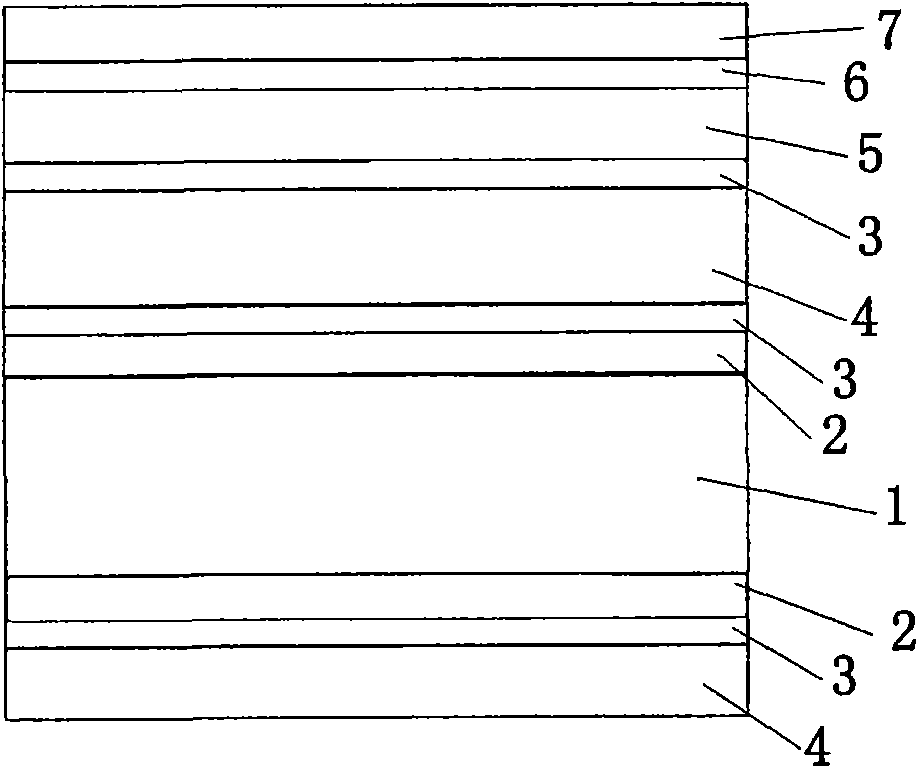

Image

Examples

Embodiment 1

[0064] Example 1: 33.3 g of 15% nano silicon oxide 1115 (particle size 4 nm), 3.1 g of 40% aliphatic polyurethane R1005, and 63.6 g of water. Add 150mg of wetting agent polyether-modified silicone BYK346 under stirring condition. Finally, a clear and transparent solution was obtained. Keep stirring for at least thirty minutes. The final solution was coated on the surface of the aluminum-plastic panel with a wire rod of 6 μm, and dried and cured at 120 degrees for one minute. The paintability of the coating solution finally obtained was 5, the antifouling ability of the coating was 7, and the coating adhesion was 5.

Embodiment 2

[0065] Example 2: 33.3 g of 15% nano silicon oxide 1115 (particle size 4 nm), 2.5 g of 40% aliphatic polyurethane R1005, and 64.2 g of water were mixed. Add 250mg of wetting agent polyether-modified silicone BYK346 under stirring condition. Finally, a clear and transparent solution was obtained. Keep stirring for at least thirty minutes. The final solution was coated on the surface of the aluminum-plastic panel with a wire rod of 6 μm, and dried and cured at 120 degrees for one minute. The paintability of the coating solution finally obtained was 5, the antifouling ability of the coating was 7, and the coating adhesion was 5.

Embodiment 3

[0066] Example 3: 33.3 g of 15% nano silicon oxide 1115 (particle size 4 nm), 2.1 g of 40% aliphatic polyurethane R1005, and 64.6 g of water were mixed. Add 250mg of wetting agent polyether-modified silicone BYK346 under stirring condition. Finally, a clear and transparent solution was obtained. Keep stirring for at least thirty minutes. The final solution was coated on the surface of the aluminum-plastic panel with a wire rod of 6 μm, and dried and cured at 120 degrees for one minute. The paintability of the coating solution finally obtained was 5, the antifouling ability of the coating was 7, and the coating adhesion was 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com