Automatic roasting device of electrolytic bath

A roasting device and electrolytic cell technology, which is applied in the field of roasting devices, can solve problems such as adverse effects on the life of the electrolytic cell, damage to the cathode carbon lining, and large expansion stress, and achieve the advantages of overcoming large temperature gradients, short start-up periods, and small expansion stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

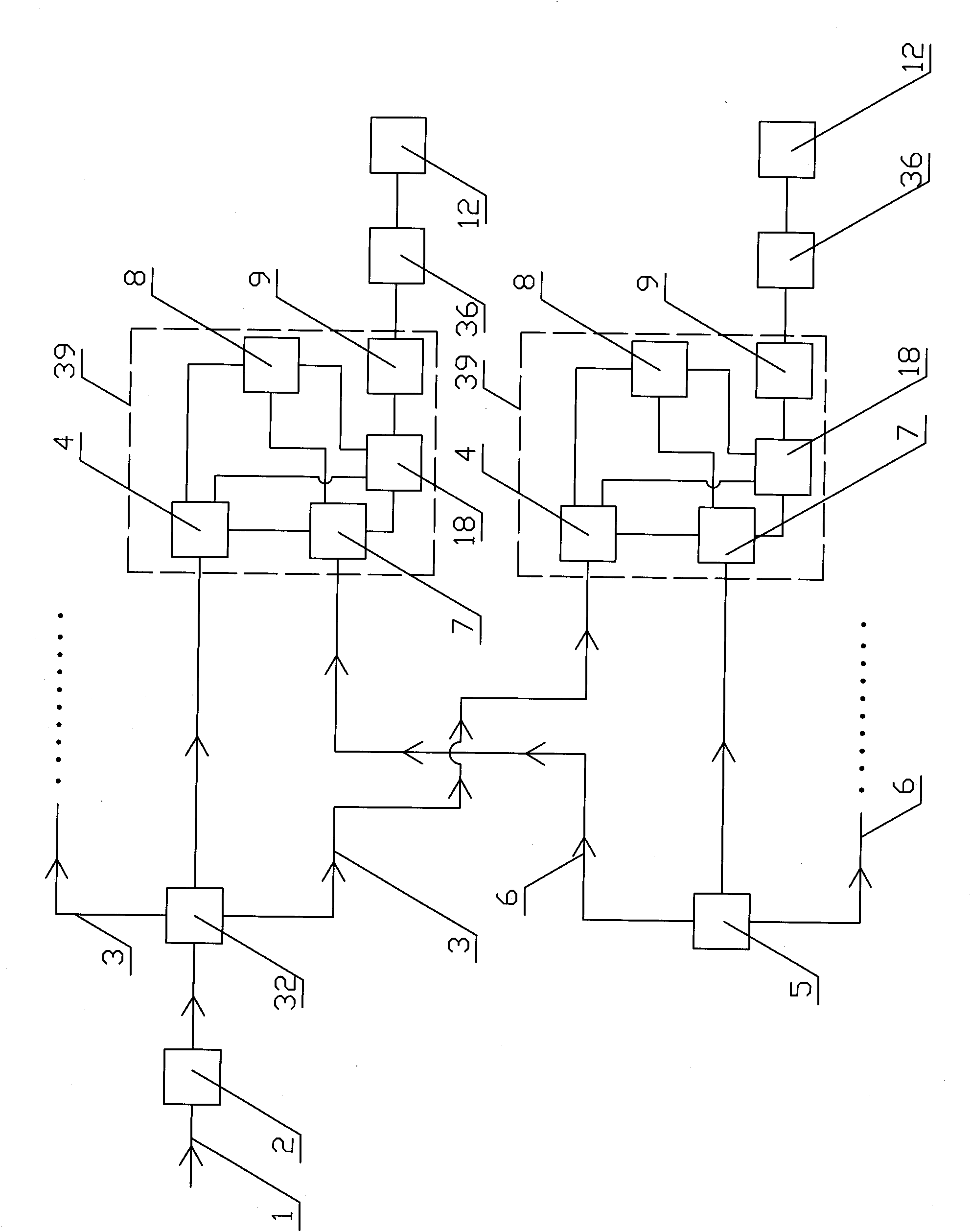

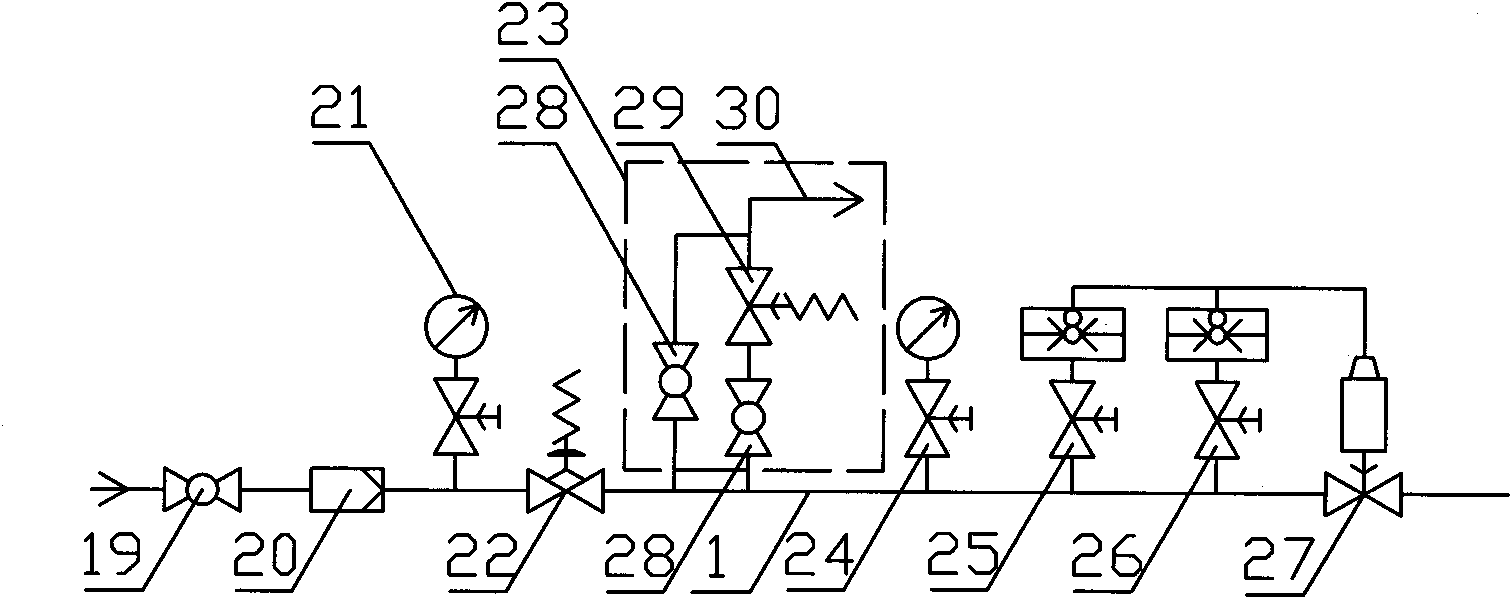

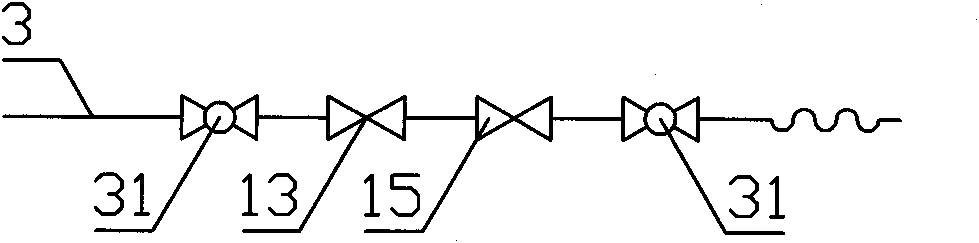

[0024] Example: such as figure 1 As shown, an automatic roasting device for an electrolytic cell includes a temperature sensor 12, a temperature control meter 36, a PID combustion controller 9; a pulse combustion controller 18, a fuel main pipeline 1, a fuel main pipeline control valve group 2, and a fuel main pipeline gas storage Tank 32, fuel branch pipeline 3, fuel branch pipeline control valve group 4, combustion-supporting wind device 5, combustion-supporting wind branch pipeline 6, combustion-supporting wind branch pipeline control valve group 7, flame combustion device 8; wherein the pulse combustion controller 18 controls the fuel branch The pipeline control valve group 4 and the combustion-supporting air branch pipeline control valve group 7. Three fuel branch pipes 3 are connected with the fuel main pipe air storage tank 32; each fuel branch pipe 3 is respectively provided with a fuel branch pipe control valve group 4. Wherein the fuel branch pipeline 3 that communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com