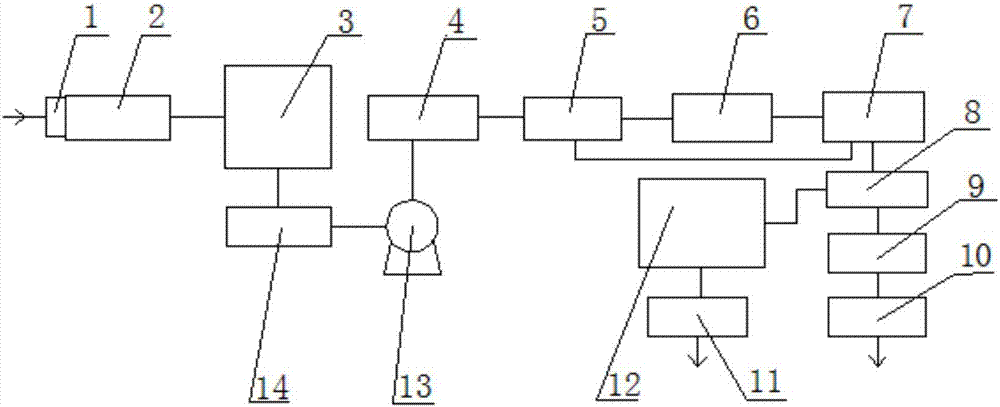

Latex paint wastewater treatment system and method

A wastewater treatment system, latex paint technology, applied in waste paint treatment, multi-stage water treatment, water/sewage treatment, etc., to prevent polarization or scaling, reduce power loss, adjust spacing and facilitate electrode plate replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

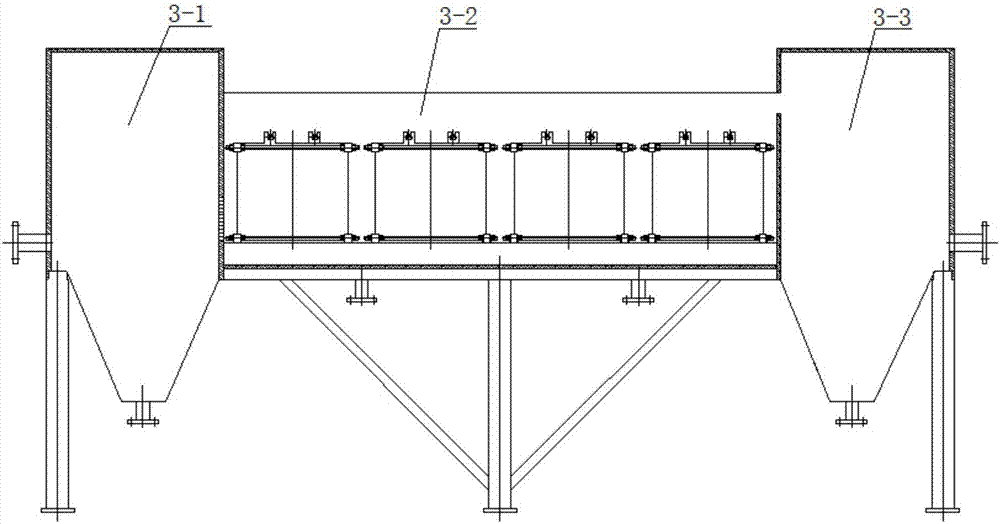

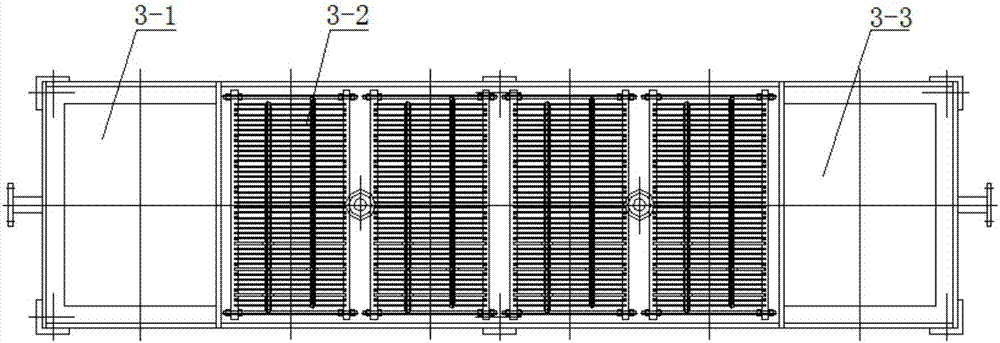

[0047] In this embodiment, the lower part of the side wall at the junction of the primary sedimentation tank 3-1 and the electrocoagulation reactor 3-2 is processed with evenly distributed water distribution holes, and the aperture of the water distribution holes is 10mm; the electrocoagulation reactor 3-2 is composed of The rectifier 3-2-1, the double-circuit cycle time relay 3-2-2, and the electrode group 3-2-3 are connected, and the number of the electrode group 3-2-3 is 1 group; two front insulating skeletons 3-2- The inner side of 3-7 is processed with 20 L-shaped slots at equal intervals along the length direction, and 20 straight slots are processed at equal intervals along the length direction on the rear insulating frame 3-2-3-1; the first rectangular electrode plate 3 - The distance between 2-3-2 and the second rectangular electrode plate 3-2-3-4 is 10 mm, the first rectangular electrode plate 3-2-3-2 and the second rectangular electrode plate 3-2-3- 4 The thickness is...

Embodiment 3

[0049] In this embodiment, the lower part of the side wall at the junction of the primary sedimentation tank 3-1 and the electrocoagulation reactor 3-2 is processed with evenly distributed water distribution holes, and the aperture of the water distribution holes is 30 mm; the electrocoagulation reactor 3-2 is composed of The rectifier 3-2-1, the double-circuit cycle time relay 3-2-2, and the electrode group 3-2-3 are connected, and the number of electrode groups 3-2-3 is 5 groups; two front insulating frames 3-2- The inner side of 3-7 is processed with 30 L-shaped slots at equal intervals along the length direction, and 30 straight slots are processed at equal intervals along the length direction on the rear insulating frame 3-2-3-1; the first rectangular electrode plate 3 - The distance between 2-3-2 and the second rectangular electrode plate 3-2-3-4 is 30 mm, the first rectangular electrode plate 3-2-3-2 and the second rectangular electrode plate 3-2-3- 4 The thickness is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com