Mixed membrane biological method anaerobic fermentation reactor for kitchen wastewater, and treatment process thereof

A kitchen wastewater and anaerobic fermentation technology, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of poor three-phase separation effect, low volume loading rate, and poor effluent quality, so as to reduce impact, low investment cost, and improve effluent The effect of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

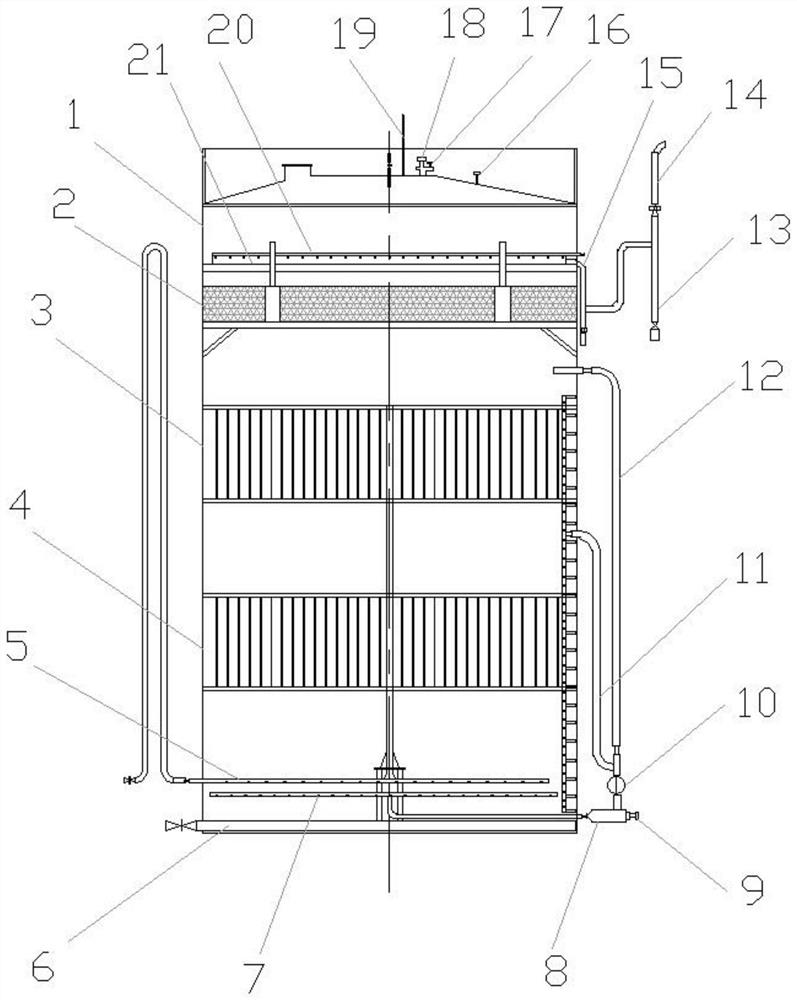

[0036] figure 1 It shows a mixed membrane bio-anaerobic fermentation reactor for kitchen waste water, including a tank body 1, in which three separation zones, a second reaction zone 3, and a first reaction zone are sequentially arranged from top to bottom. Zone 4, biogas gas distribution device 5, water distributor 7 and mud discharge system 6, the mud discharge system includes mud discharge pipes, specifically as in the prior art; the three-phase separation zone 2 is arranged from top to bottom A pressure beam, a three-phase separator and a bottom beam, a water outlet weir 21 is arranged above the pressure beam, and the water outlet weir 21 is connected with an outlet pipe 15 protruding from the outside of the pipe body, and a backwash pipe is arranged above the water outlet weir 21 20; the second reaction zone 3 and the first reaction zone 4 are both biofiller reaction zones, both of which are fixed with biofilm layers through membrane frames, and are connected in series to...

Embodiment 2

[0055] The present invention also provides a treatment process for kitchen waste water mixed membrane biological anaerobic fermentation reactor, the biological fillers in the second reaction zone 3 and the first reaction zone 4 are knotted and tied rope-type biological fillers, The ring-shaped fibers adopting the high-strength polypropylene weaving process form a radial structure, which increases the built-in surface area, makes the sludge in the mixture stay in the first reaction zone 4 and the second reaction zone 3, and granulates the sludge that stays, making the granulation Microorganisms are attached to the surface of the sludge, which effectively improves the biofilm and improves the efficiency of the anaerobic reaction; the treatment process also includes the following steps:

[0056] a. The bottom of the reactor is fed with water, and the granular sludge and the mud-water mixture returned from the gas-liquid separation zone are mixed at the bottom of the reactor, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com