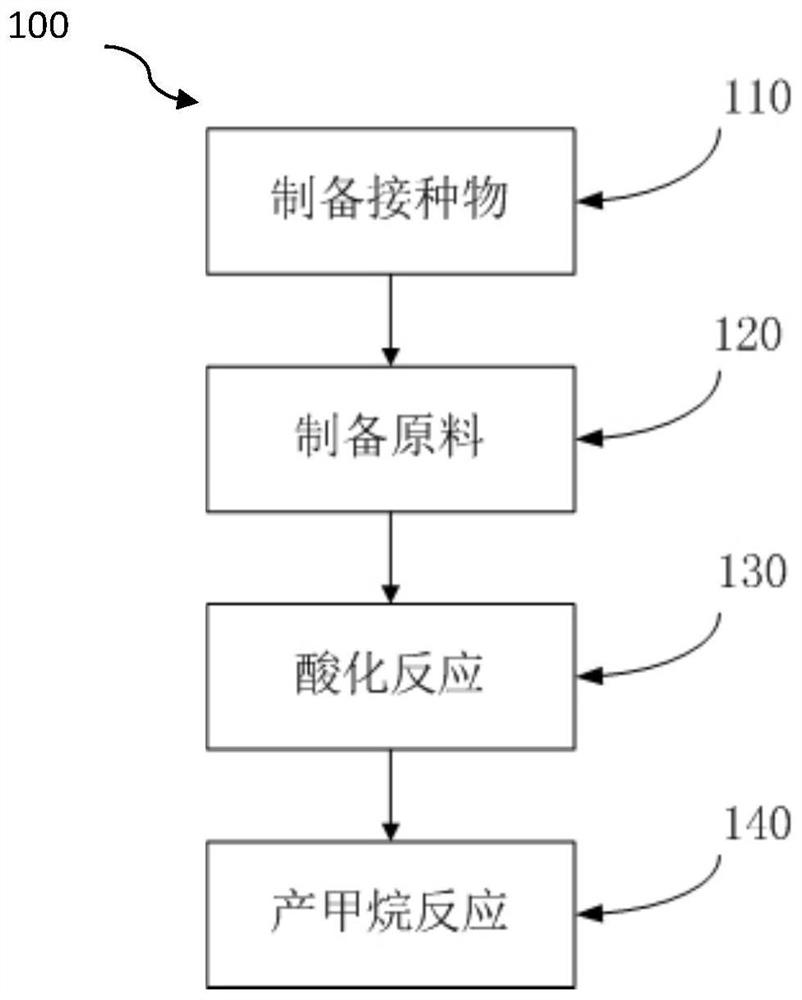

Method for producing biogas from palm oil manufacturing wastewater

A palm oil and wastewater technology, applied in chemical instruments and methods, gas fuels, waste fuels, etc., can solve the problems of particle loss, particle scouring, and long startup cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

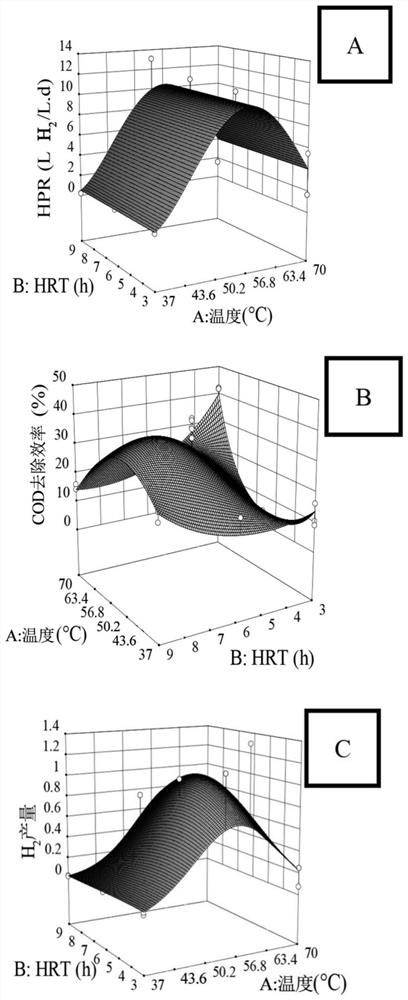

[0053] Materials and Methods

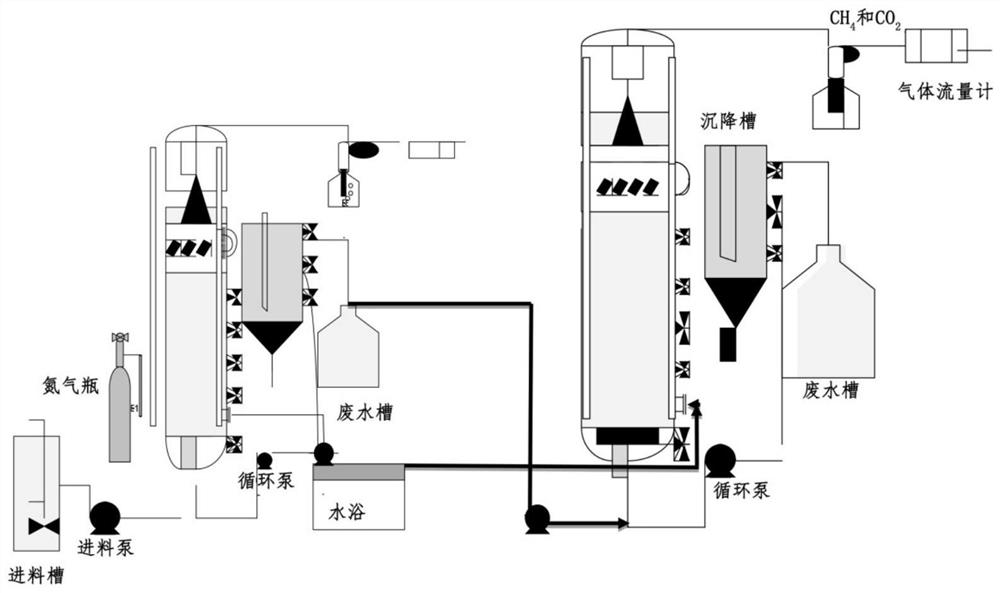

[0054] A two-stage UASFF bioreactor was prepared, which consisted of two parts: H for conducting a dark fermentation process to produce biohydrogen 2 -UASFF unit, and CH for anaerobic fermentation to produce biomethane 4 -UASFF unit. The schematic diagram of the bioreactor setup is shown in figure 2 shown.

[0055] Culture medium and substrate preparation

[0056] POME was collected in the anaerobic pond of a palm oil mill in Banting (Selangor, Malaysia). This POME is characterized as digested POME. Sludge was adapted in a single-stage UASFF bioreactor at 10 g L -1 Glucose solution was fed as substrate to generate biogas until its pH was stabilized between 7-8, the percentage of methane in the biogas was always kept at 70% or higher, and the final wastewater COD removal rate was 76.34%. The first part of the adapted sludge will be used as H 2 - The inoculum for biohydrogen production in the UASFF system was diluted with water and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com