Fiber bitumen macadam seal coat method

An asphalt crushed stone and fiber technology, applied in the field of road maintenance, can solve the problems of inconsistent consistency of slurry mixture, inconsistent oil-to-stone ratio, and different smoothness, etc., and achieves the effect of strong extension force, improved service life, and suppression of reflective cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

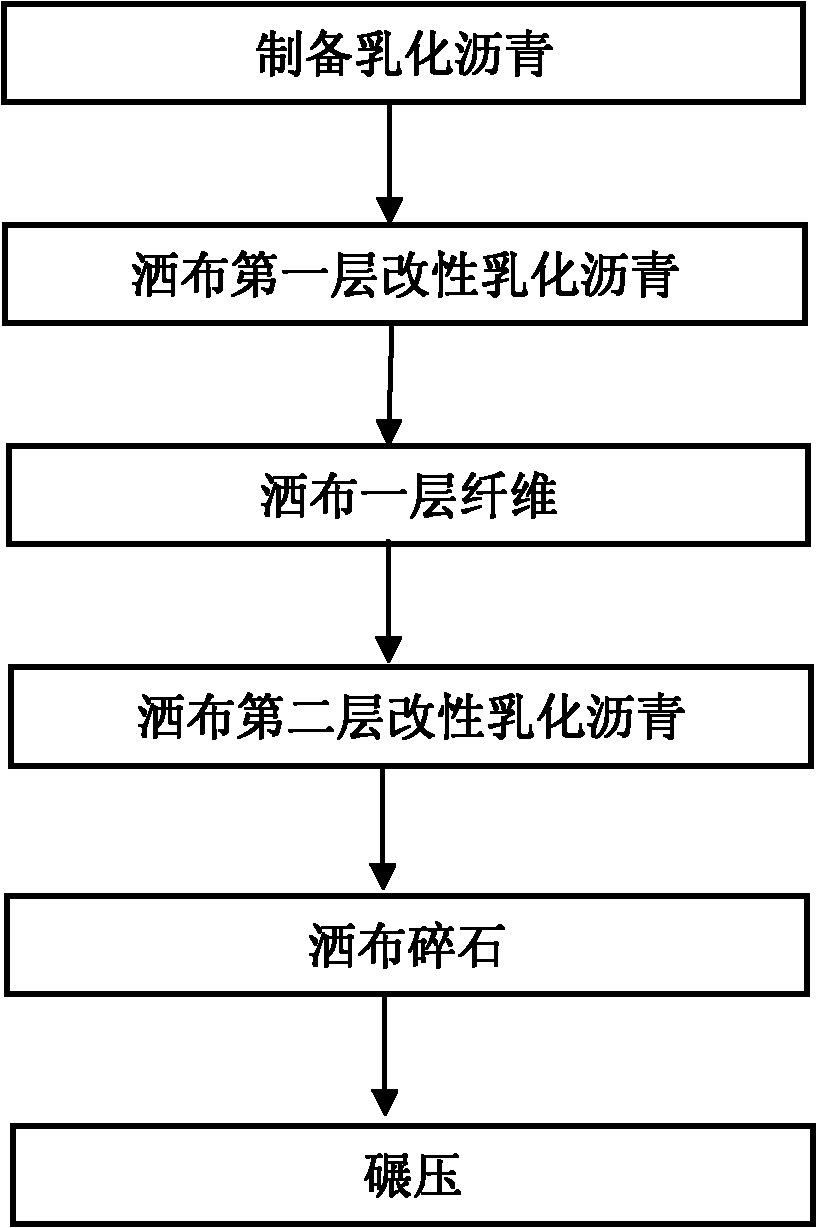

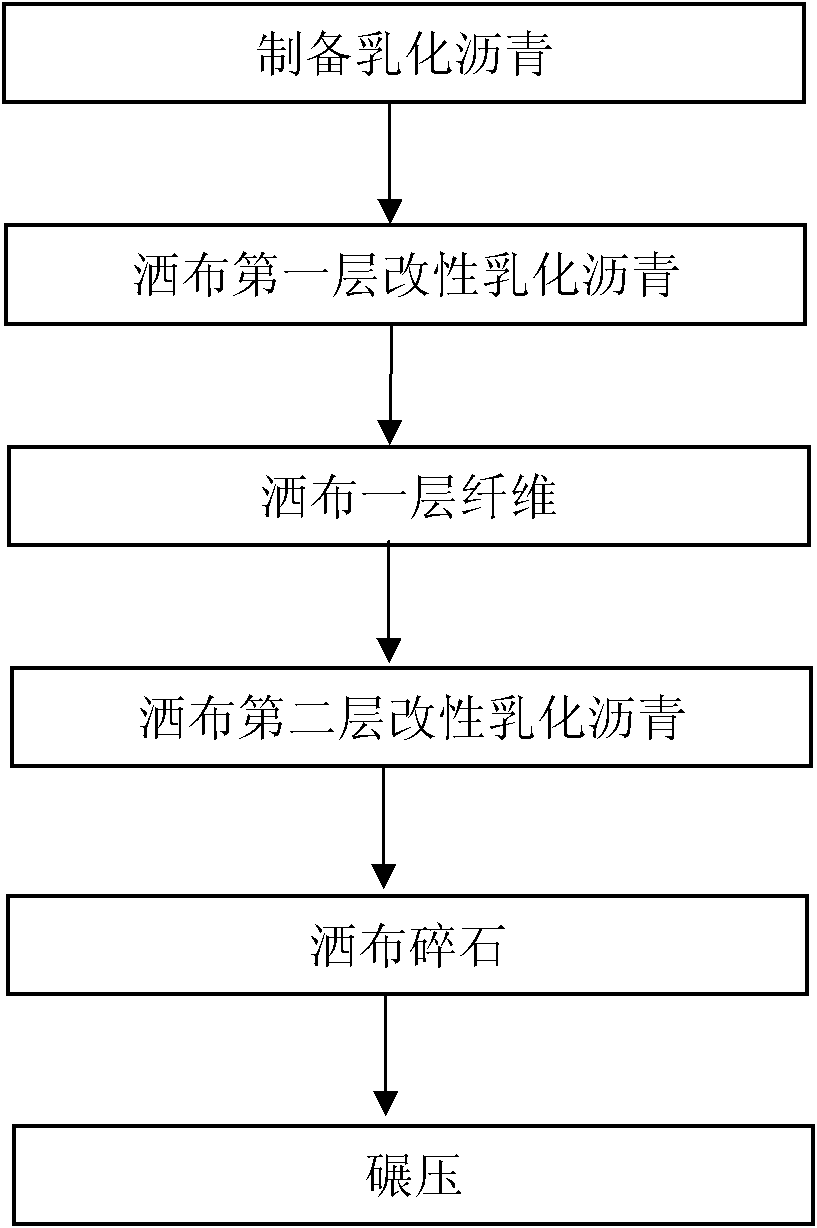

[0042] Below in conjunction with accompanying drawing, the present invention is described in further detail, see figure 1 :

[0043] Implementation column 1

[0044] A kind of fibrous asphalt gravel sealing method:

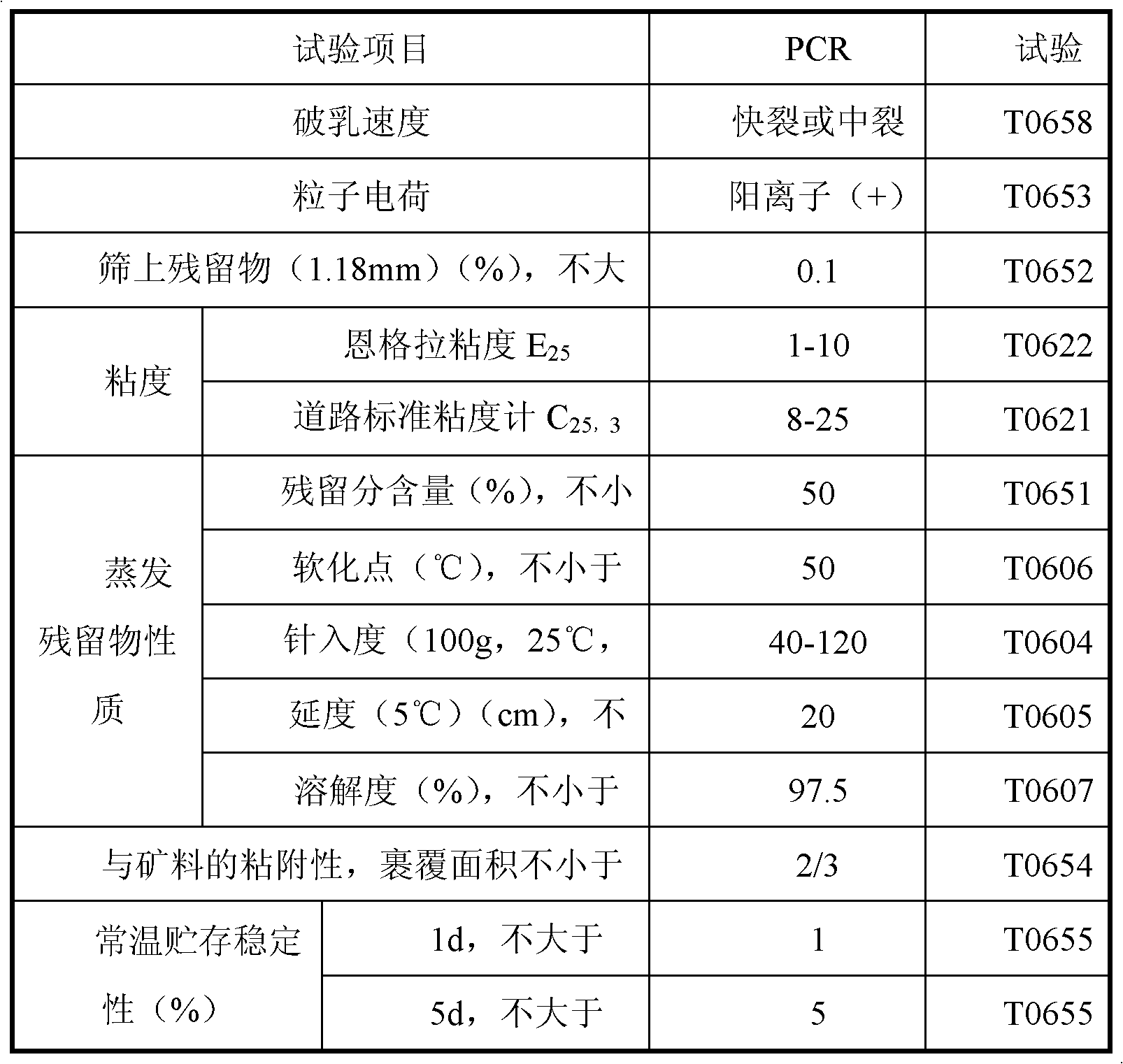

[0045] (1) Preparation of emulsified asphalt: according to the volume ratio of asphalt and soap liquid is 62.8:37.2, mix evenly and keep warm at 60°C for 0.5 hours to prepare emulsified asphalt; add 2.5% modifier latex to the emulsified asphalt and stir until uniform to obtain modified emulsified asphalt;

[0046] (2) Sprinkle the first layer of modified emulsified asphalt;

[0047] (3) Sprinkle a layer of fiber: the amount of fiber should be 50-70g / m 2 , length 60mm;

[0048] (4) Sprinkle the second layer of modified emulsified asphalt;

[0049] (5) Spread gravel;

[0050] (6) Rolling: Rolling 2 to 5 times, the initial pressing speed should not exceed 2km / h, and the re-pressing rolling speed should be controlled at 2.0km / h.

[0051] In the steps (2)-(4), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com