Mini elliptic gear engine

An oval gear and engine technology, applied in the field of miniature four-stroke engines, can solve the problems of long and narrow cylinder shape, low combustion efficiency, high fuel consumption, and achieve the effects of easy production, reduced overall machine volume, and low precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Various parts of the engine

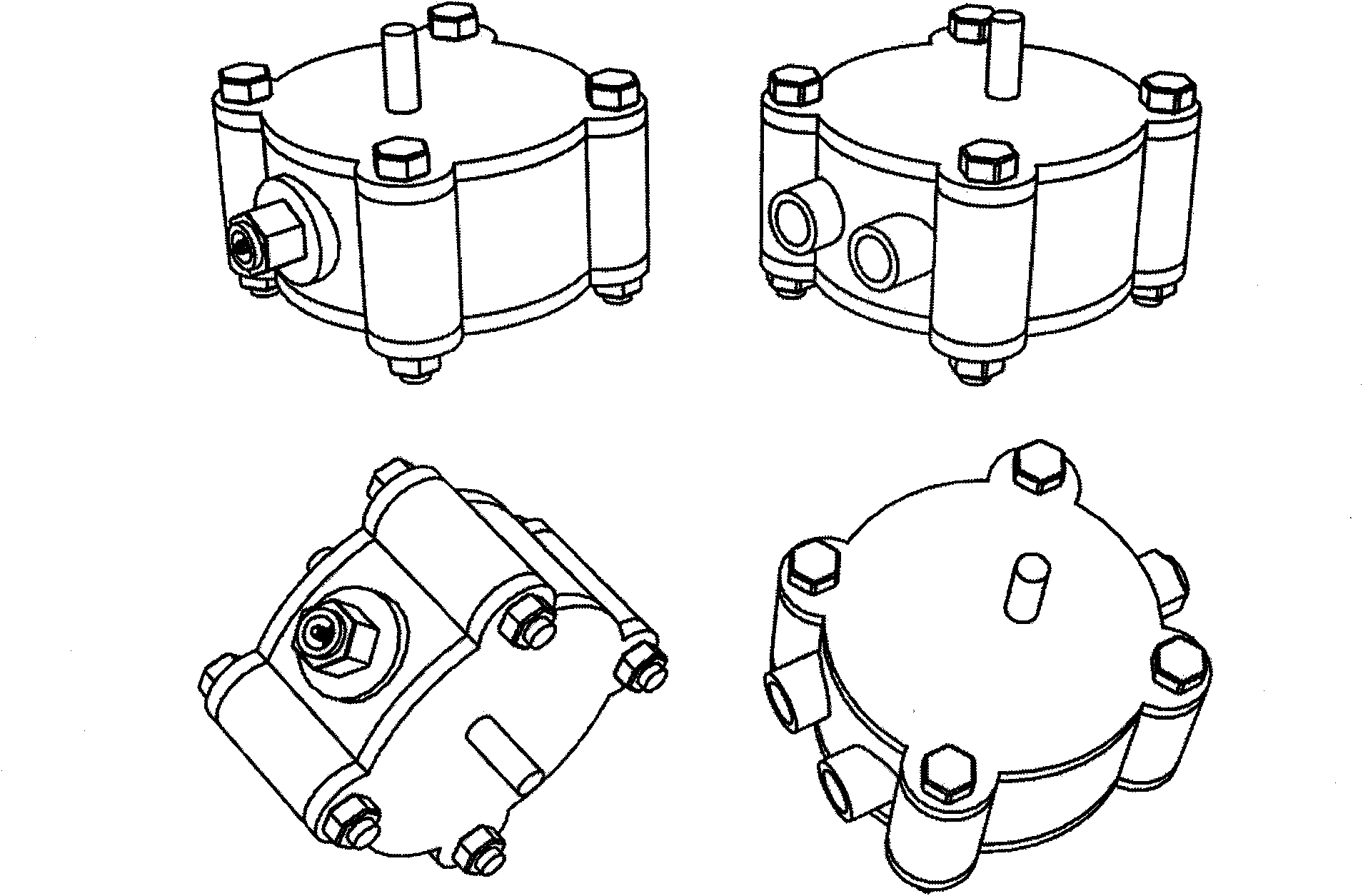

[0030] Such as figure 1 As shown, it is a schematic diagram of the appearance of the whole machine. From the figure, it can be clearly understood that the engine is a cylinder. side. The engine is provided with two air ports on the circumferential surface of the cylinder, which are respectively an air inlet and an exhaust port. The air port is located on one side of the circumferential surface, and a glow plug is installed on the other side to be responsible for ignition. Bolts are installed around the engine to fix the whole machine.

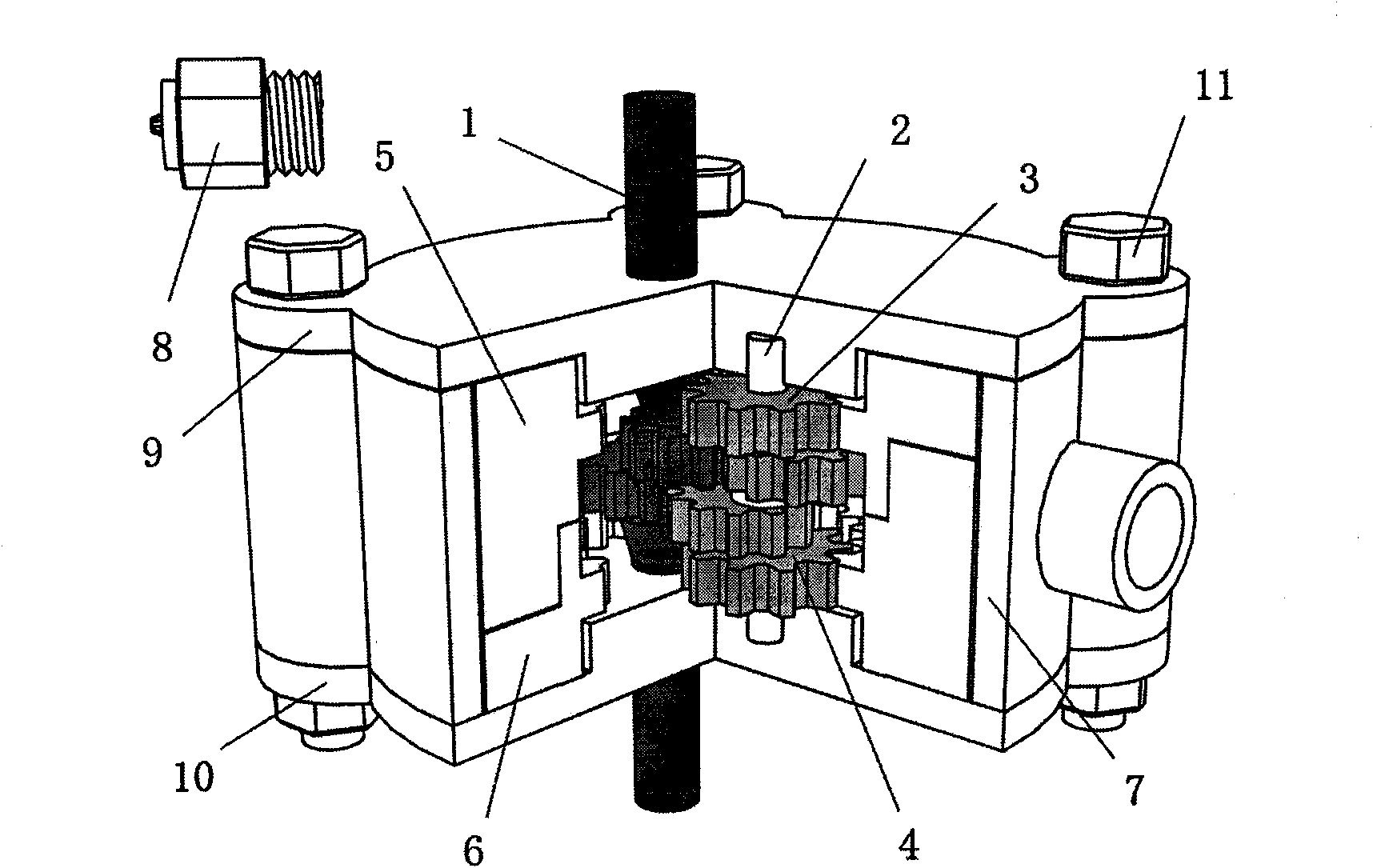

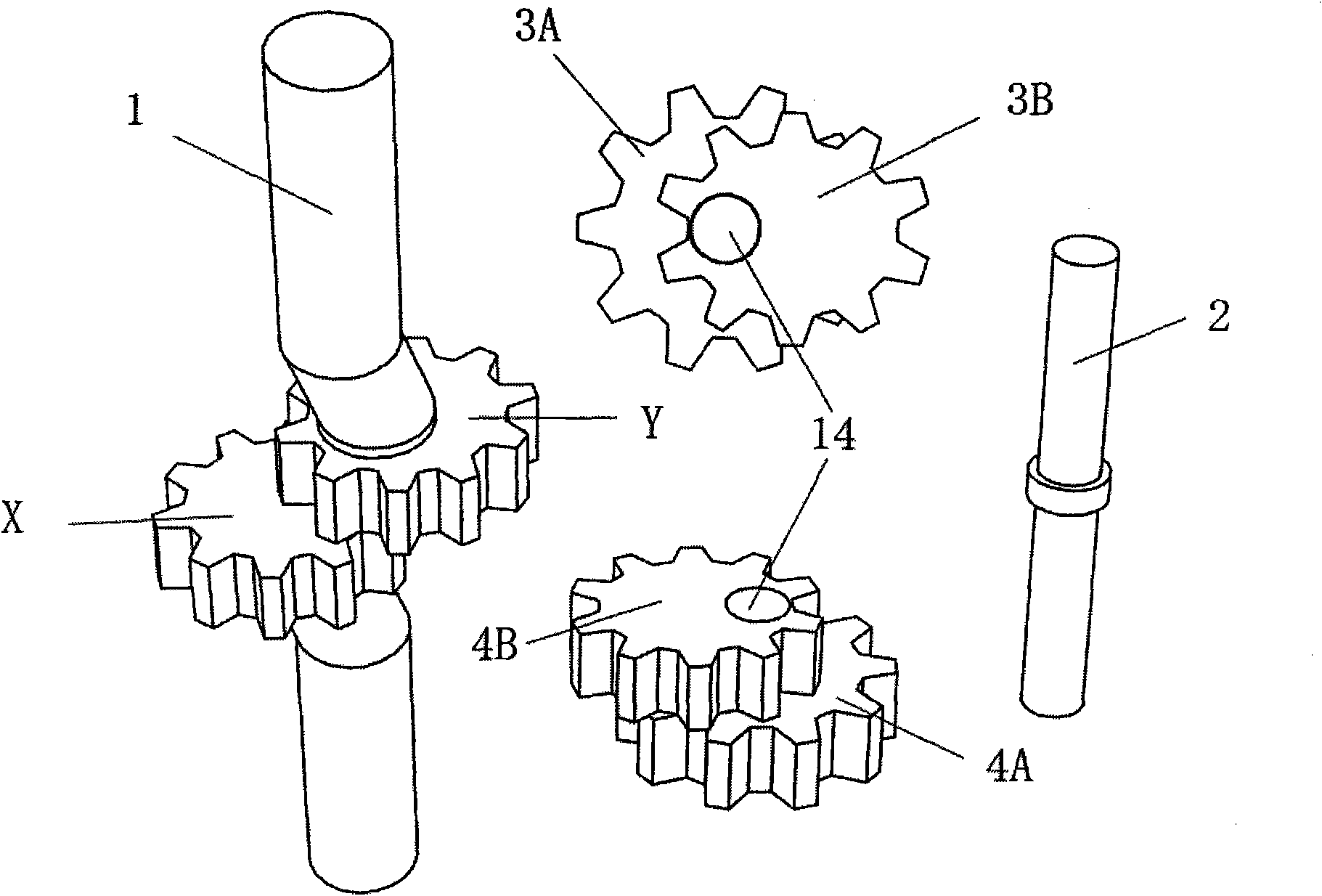

[0031] Such as figure 2 As shown, it is a schematic diagram of the internal dissection of the whole machine, from which the main technical features of the present invention can be clearly understood, wherein the output shaft (1) passes through the upper cover (9) and the lower cover (10) and can be inside the body Rotate, the gear shaft (2) is parallel to the output shaft (1) and is fixed between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com