Rectifier for use at high temperature

A rectifier and conditional technology, applied in the field of rectifiers, can solve problems such as excess energy, waste, and large leakage current, and achieve the effects of improving impact resistance, improving component damage, and low reverse leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

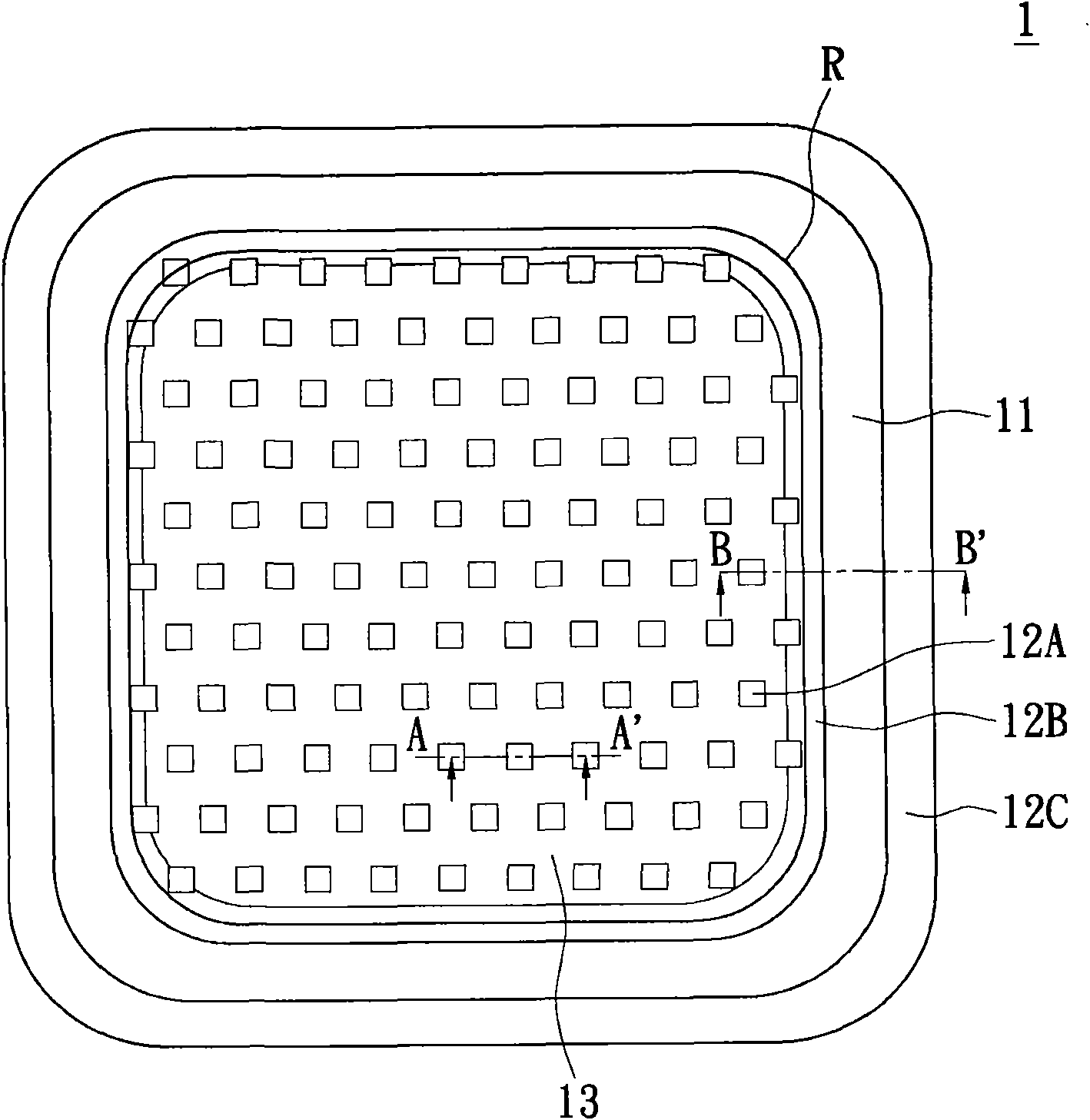

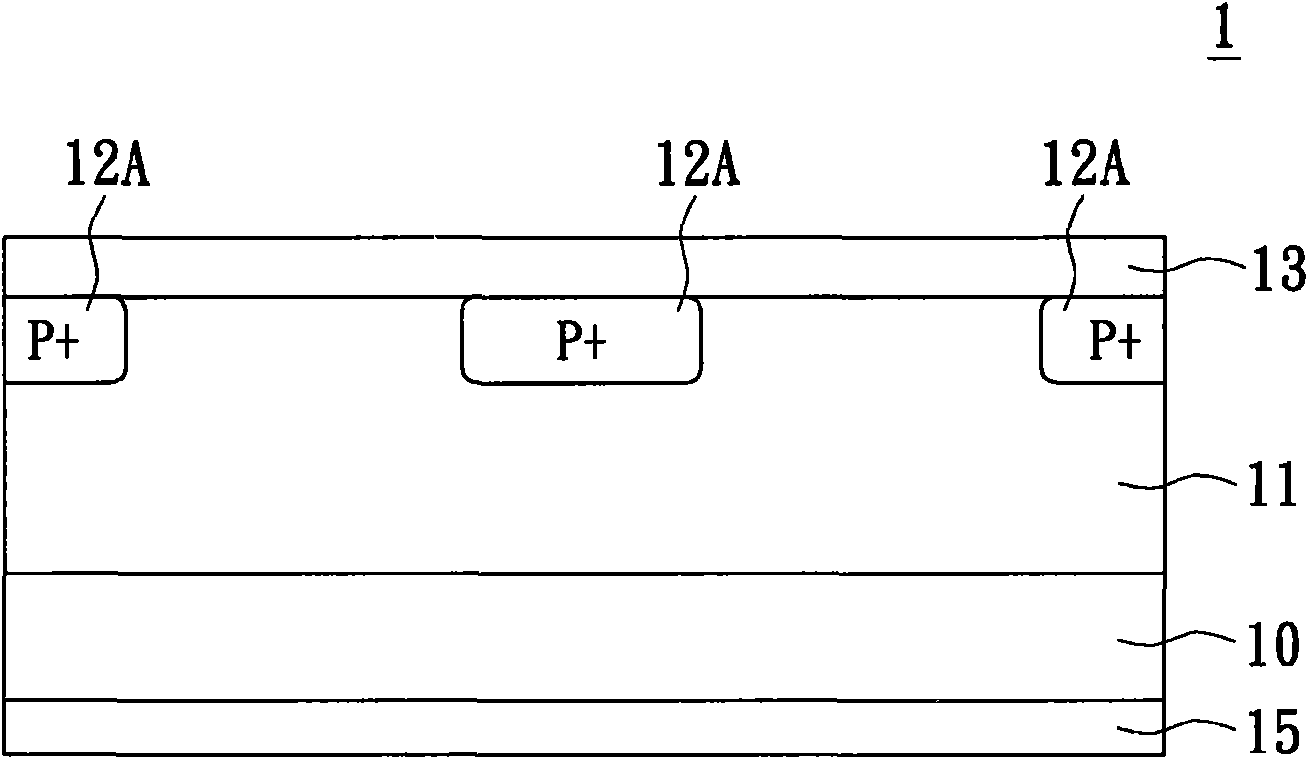

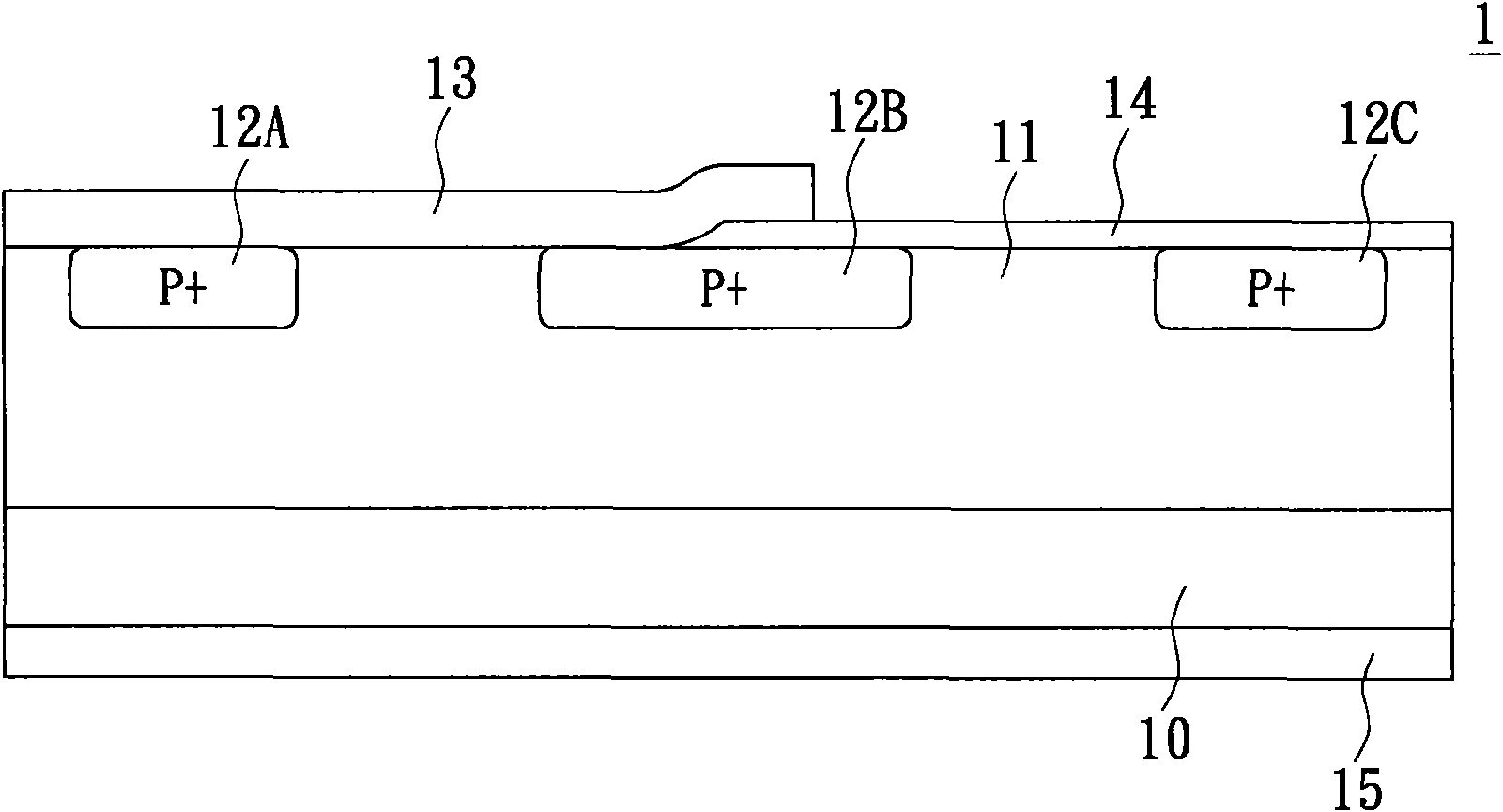

[0039] see figure 1 , the present invention provides a rectifier 1 applied under high temperature conditions. The rectifier 1 has high efficiency under high temperature operating conditions and high reliability when operating at high reverse voltage. The rectifier 1 includes a conductive semiconductor substrate 10. Conductive type epitaxial layer 11, multiple conductive type doped regions 12A, an edge conductive type doped region 12B, at least one outer edge conductive type doped region 12C, a first metal layer 13, and a second metal layer 15 (see also Figure 1A and Figure 1B ).

[0040] figure 1 A specific embodiment of the present invention is shown, wherein the conductive semiconductor substrate 10 is an N-type semiconductor substrate, the conductive epitaxial layer 11 is also an N-type epitaxial layer, and according to different doping concentrations, the conductive semiconductor substrate 10 is represented by N+, and the conductivity type epitaxial layer 11 is repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com