Metal power-driven ship

A metal and power technology, applied in motor-driven engines, fuel cell-type half-cells, and primary-battery-type half-cells, etc., can solve the problems of restricting the application of electric ships, time-consuming and laborious replacement, and large land occupation. Self-discharge phenomenon, reduce pollution, maintain stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

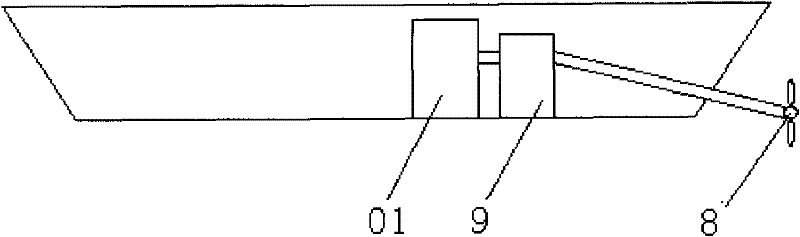

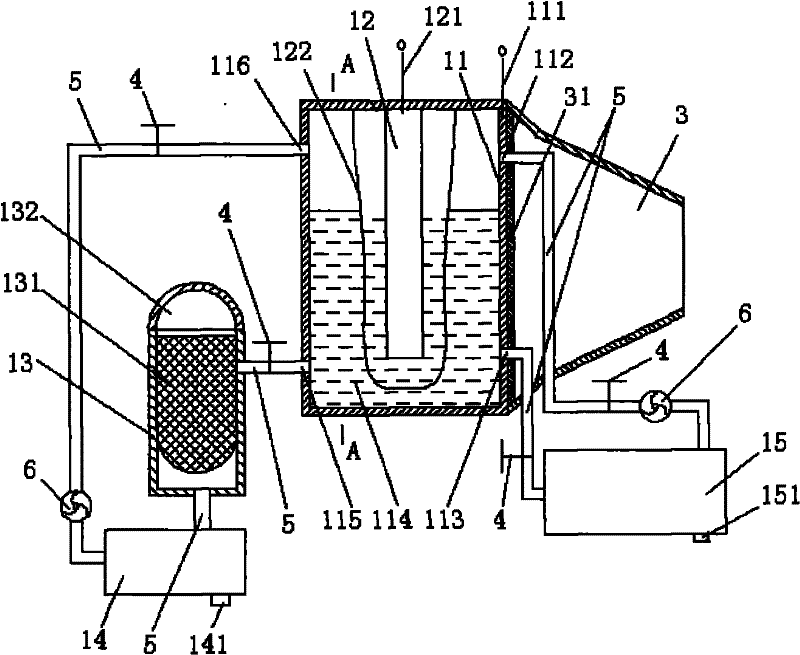

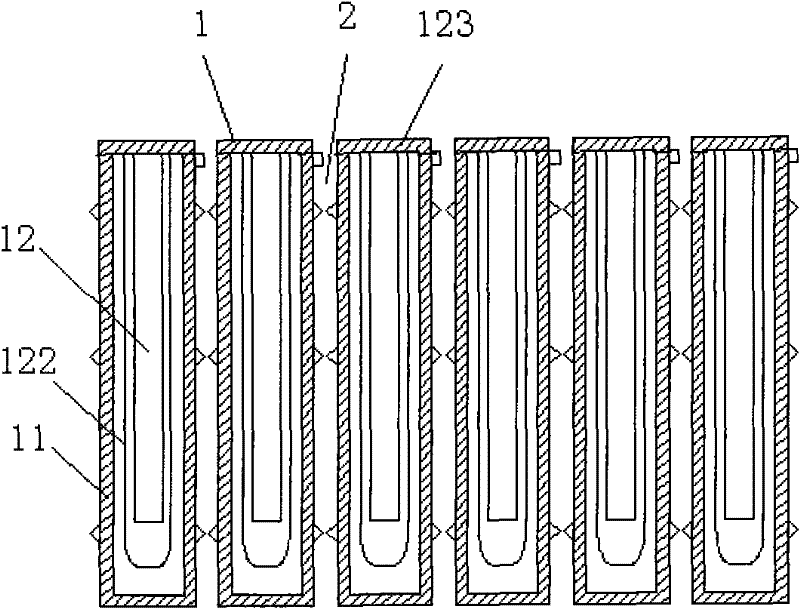

[0019] The metal power ship provided by the present invention includes a hull 7, a propeller 8 installed on the hull 7 and an electric energy driver 9, and a carbon-free metal power generation device 01 that provides electric energy to the electric energy driver 9, such as figure 1 , wherein: the carbon-free metal power generation device is composed of a plurality of reaction units 1 spaced side by side to form a power generation group, an air channel 2 is formed between two reaction units 1, and an air filter is provided at the inlet end of the air channel 2, and the air filter Including the air supply pipe 3, the filter cloth 31 arranged at the outlet of the air supply pipe 3, so that while supplying air to the air passage 2, the particulate matter, pollutants and dust in the air are filtered through the filter cloth 31 to prevent the air passage 2 of the generating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com