Mixture for preventing the diffusion of contaminating component and method of preventing the diffusion of contaminating component

A technology for preventing pollution and mixtures, applied in the restoration of contaminated soil, silicon compounds, chemical instruments and methods, etc., can solve problems such as insufficient purification ability of polluted components, increased cost of adsorbents, increased construction costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

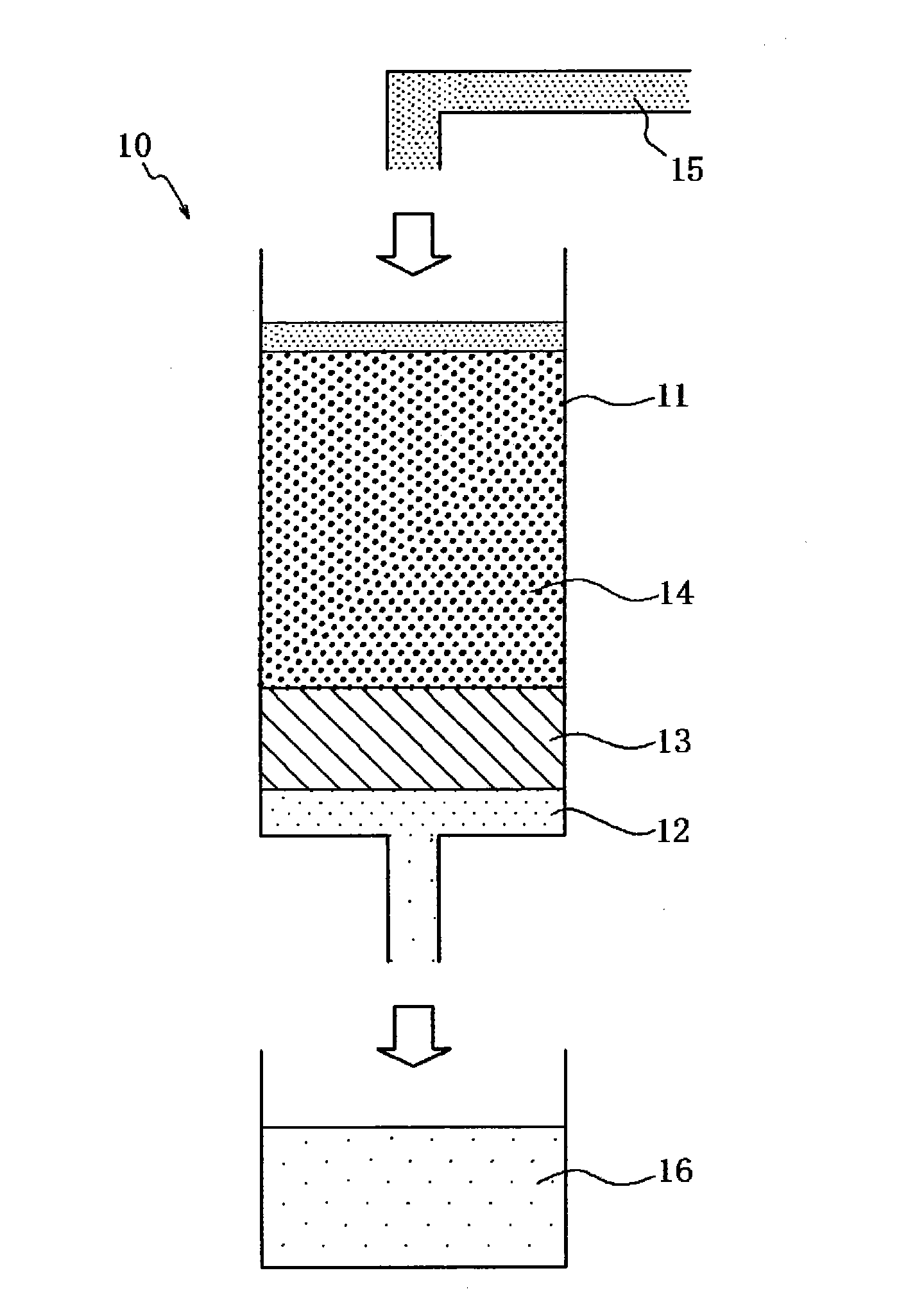

[0064] In Example 1, 50 g of a clay-like adsorbent (trade name "Adcera (registered trademark) (slurry)" manufactured by Nippon Plate Glass Co., Ltd.) (specific gravity = 1.2, 41.5 cm 3 ) and the dilution material are mixed at a volume ratio of 0.8:10, thereby forming an anti-pollution component diffusion layer, wherein the clay-like adsorbent consists of 30% by mass of a variety of rare earth compounds mainly composed of cerium, 55% by mass % of water, the balance of 15% by mass of silicon dioxide and other inorganic elements, the dilution material consists of 500cm 3 Glass fiber (short glass fiber with an average fiber diameter of 0.8 μm, "CMLF#208" manufactured by Nippon Plate Glass Co., Ltd.) and 4500 cm 3 It is composed of fine sand (sand with an average particle size of 0.3 mm). It should be noted that, since the above-mentioned diluting material is in the form of a slurry, a method of mixing with the above-mentioned glass fiber and then mixing with the above-mentioned f...

Embodiment 2

[0066]In Example 2, 50 g of clay-like adsorbent (trade name "Adcera (registered trademark) (slurry)" manufactured by Nippon Plate Glass Co., Ltd.) (specific gravity = 1.2, 41.5 cm 3 ) and the dilution material are mixed in a ratio of 1:1 by volume, thus forming an anti-pollution component diffusion layer, wherein the clay-like adsorbent consists of 30% by mass of a variety of rare earth compounds mainly composed of cerium, 55% by mass % of water, the balance of 15% by mass of silicon dioxide and other inorganic elements, the dilution material consists of 500cm 3 Asbestos (cotton-like material of rock material with an average fiber diameter of 4 μm, "S-fiber (registered trademark)" manufactured by Nichika Asbestos Co., Ltd.) and 500 cm 3 It is composed of fine sand (sand with an average particle size of 0.3 mm). It should be noted that, since the above-mentioned diluting material is in the form of a slurry, the method of mixing with the above-mentioned asbestos and then mixing...

Embodiment 3

[0068] In Example 3, 100 g of granular adsorbent (trade name "Adcera (registered trademark) (granular)" manufactured by Nippon Plate Glass Co., Ltd.) (specific gravity = 0.75, 75 cm 3 ) and the dilution material are mixed at a volume ratio of 0.75:10, thus forming an anti-pollution component diffusion layer, wherein the granular adsorbent consists of 40% by mass of a variety of rare earth compounds with cerium as the main component and 60% by mass % of other inorganic elements such as silica, the diluted material consists of 1000cm 3 Sand (average particle size 0.75mm) composition. Table 2 shows the water permeability coefficient, thickness and space velocity of the formed pollution prevention component diffusion layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com