Device capable of realizing accurate control of equal-channel angular extrusion processing route

A technology of equal-channel corner and extrusion processing, which is applied in the direction of metal extrusion control equipment, metal extrusion, metal processing equipment, etc., can solve the problem that the operator cannot determine the rotation angle, cannot accurately control the rotation angle, and is inconvenient for samples Re-insertion and other issues, to achieve reliable performance, simple structure, easy to put in the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

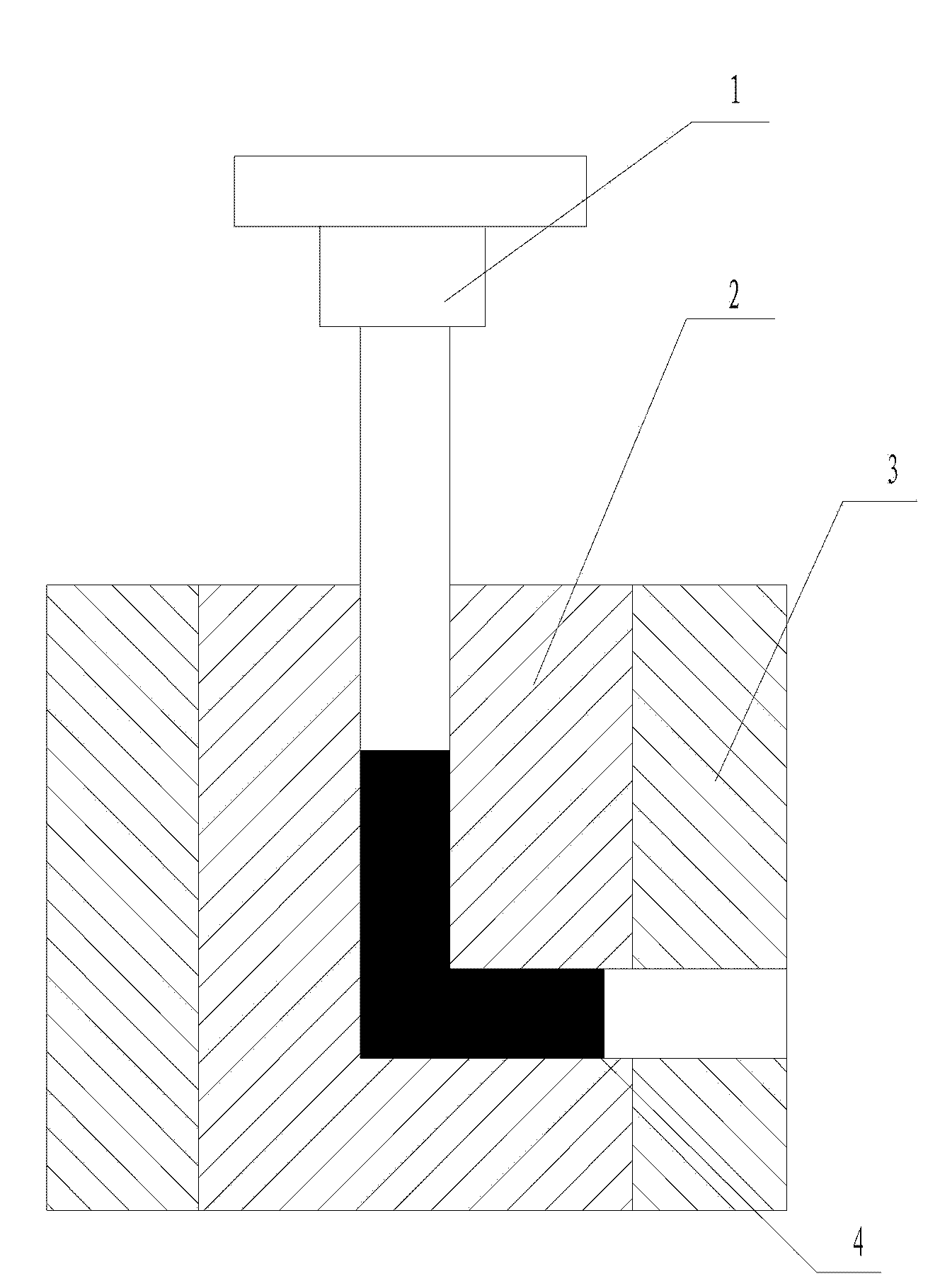

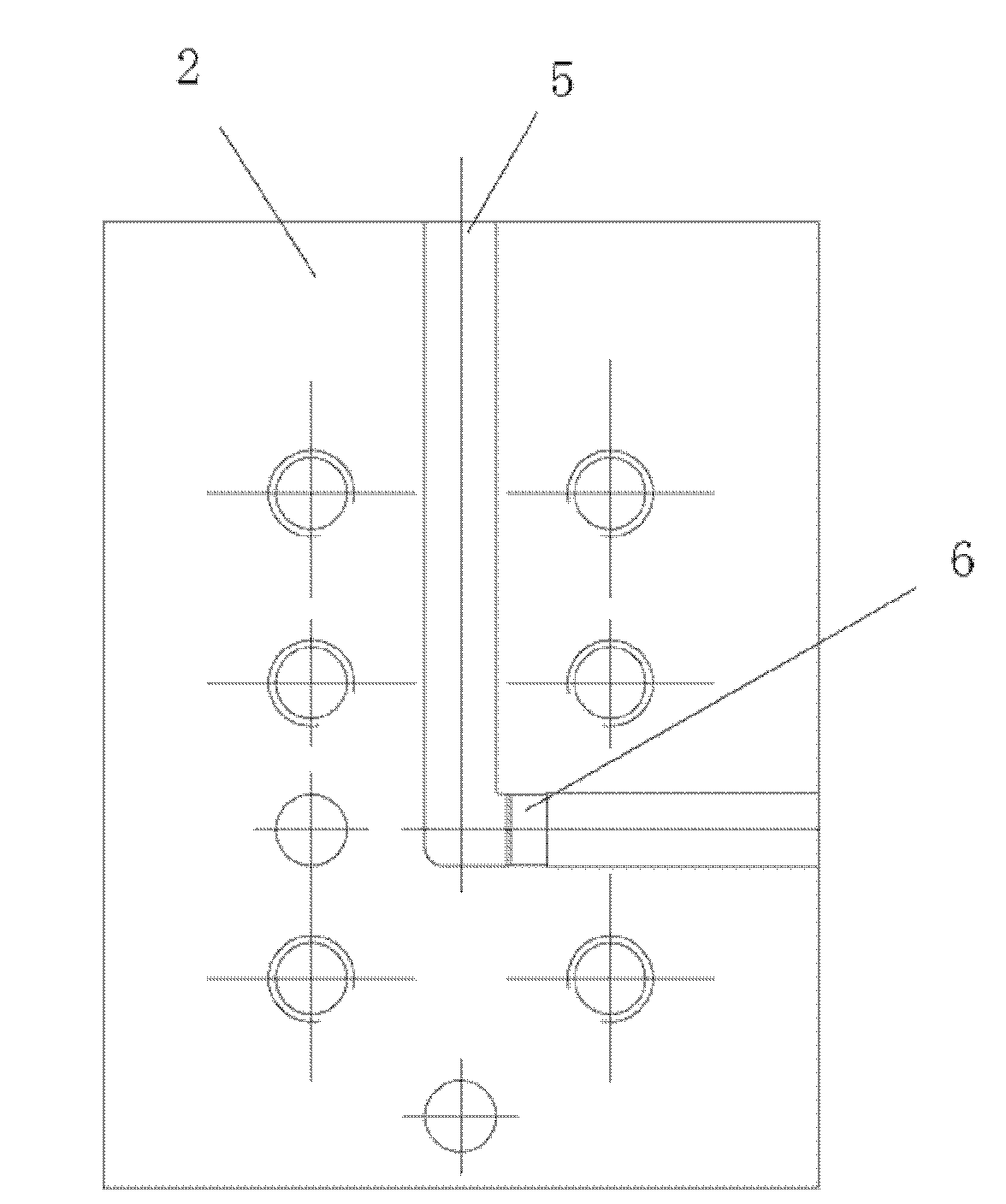

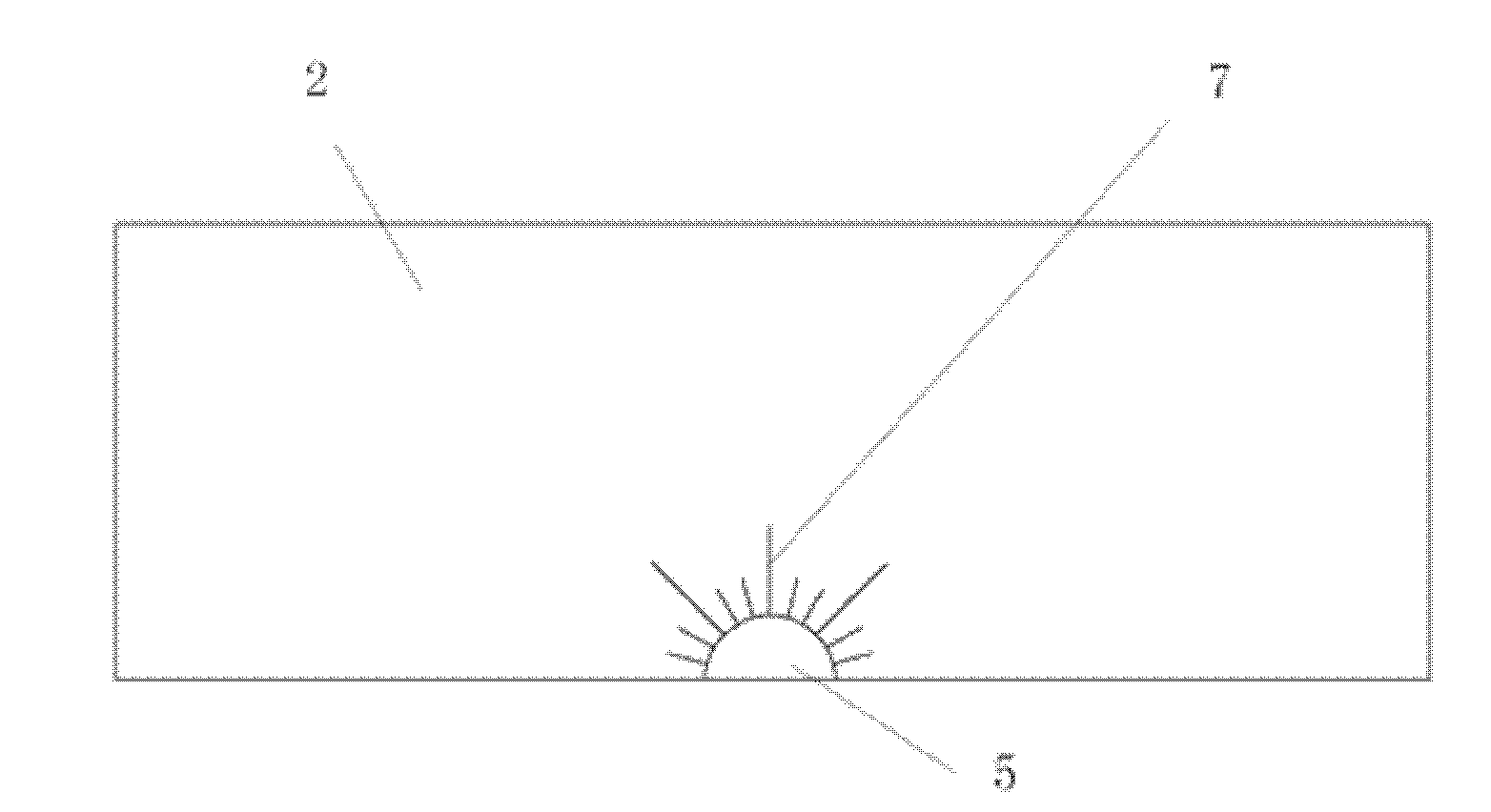

[0019] see figure 1 , figure 2 and image 3 , the extrusion die 2 is divided into two halves of the die connected by a plurality of bolts, the two halves of the die are positioned by pins, and the periphery of the extrusion die 2 is provided with a fixed ring 3 for fixing, and the fixed ring 3 is connected with the extrusion The die 2 is an interference fit. The cross section of the die channel 5 of the extrusion die 2 is a regular polygon with the number of sides N≥4. A section of extrusion with a slightly smaller cross-sectional size is provided near the corner of the exit channel of the die channel 5. The pressure channel 6 and the rest of the outlet channel of the die channel 5 have the same size as the inlet channel; the surface of the entrance of the die channel 5 is provided with scales 7 at equal intervals.

[0020] see figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com