Precision ball screw manufacturing method

A ball screw and a manufacturing method technology, applied in the transmission field, can solve the problems of short tempering time, long grinding time, rough surface, etc., and achieve the effects of saving machining time, improving production efficiency, and low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with example:

[0033] 38CrMoAl is selected as the material of the screw, and the manufacturing process steps of the precision ball screw based on the pulse electrochemical composite finishing technology are as follows:

[0034] Blanking, straightening, turning outer circle, quenching and tempering, repairing center hole, grinding outer circle, thread grinding and grinding screw thread, milling keyway or square body, fitter process, stress relief, center hole grinding, glow ion nitrogen Chemical, pulse electrochemical composite finishing, chamfering 1 / 4 turn of incomplete teeth at both ends, thread grinding and chamfering threads, and finally 45° treatment on the top.

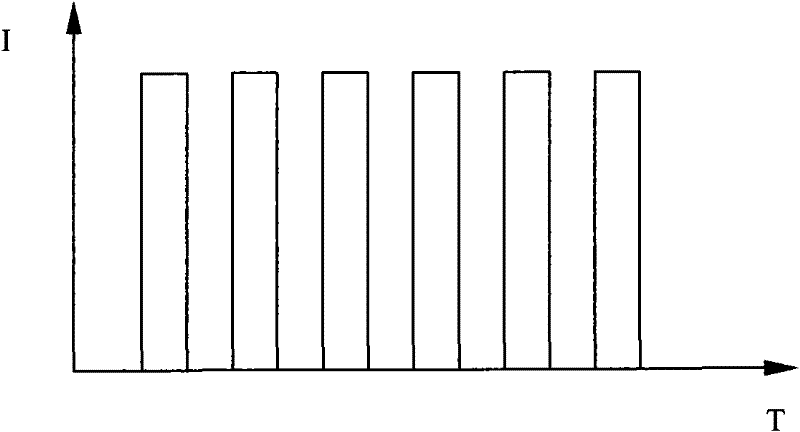

[0035] Wherein, the application of the pulse electrochemical composite finishing technology in the process of the present invention is unique to the present invention, and the specific process parameters are as follows:

[0036] 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com