Corrosion inhibitor used for protecting ancient cast iron antiques

A technology for protection of cultural relics and corrosion inhibitor, applied in the field of corrosion inhibitor, can solve problems such as changing the appearance of cultural relics, and achieve the effect of improving corrosion inhibition effect and good corrosion inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

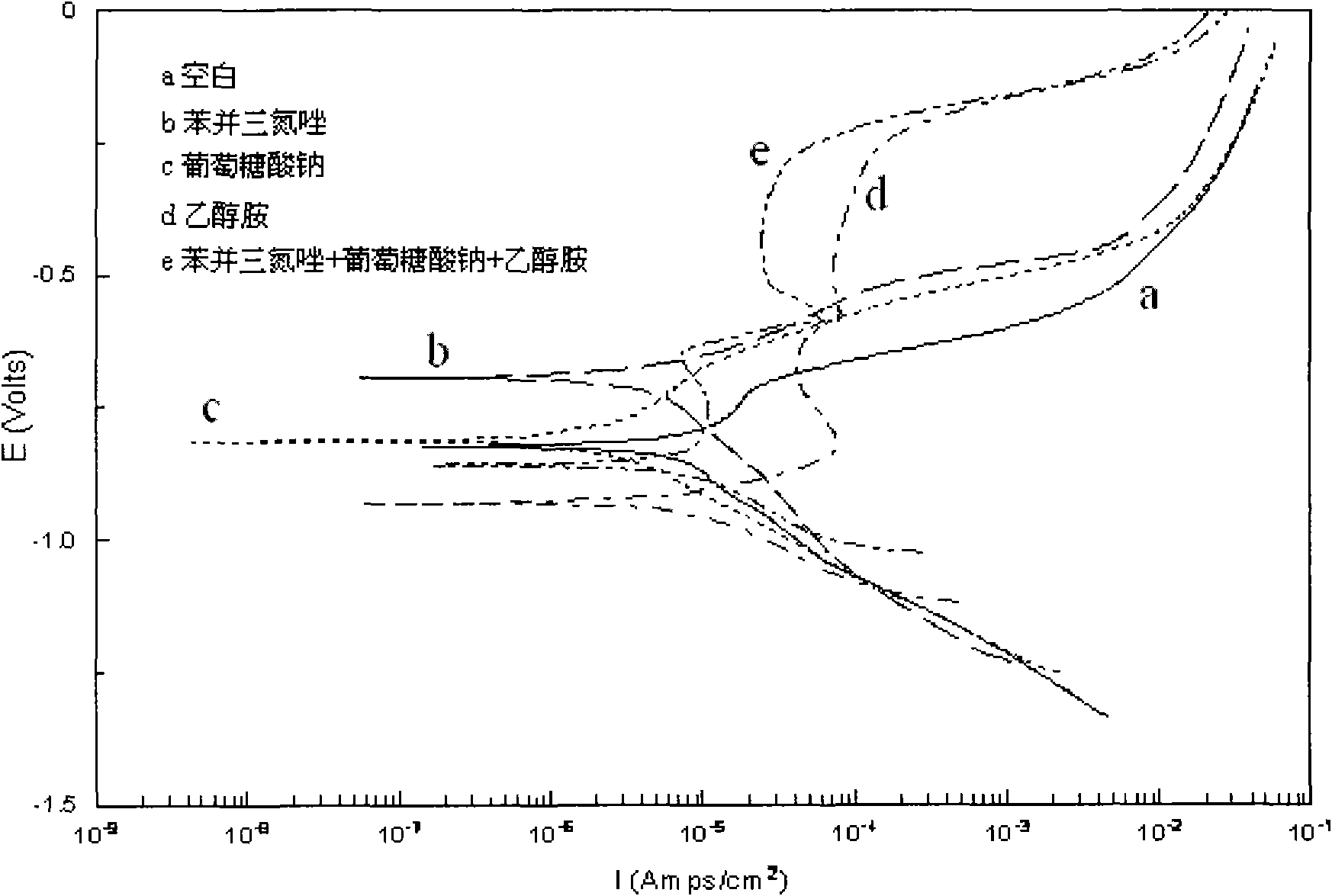

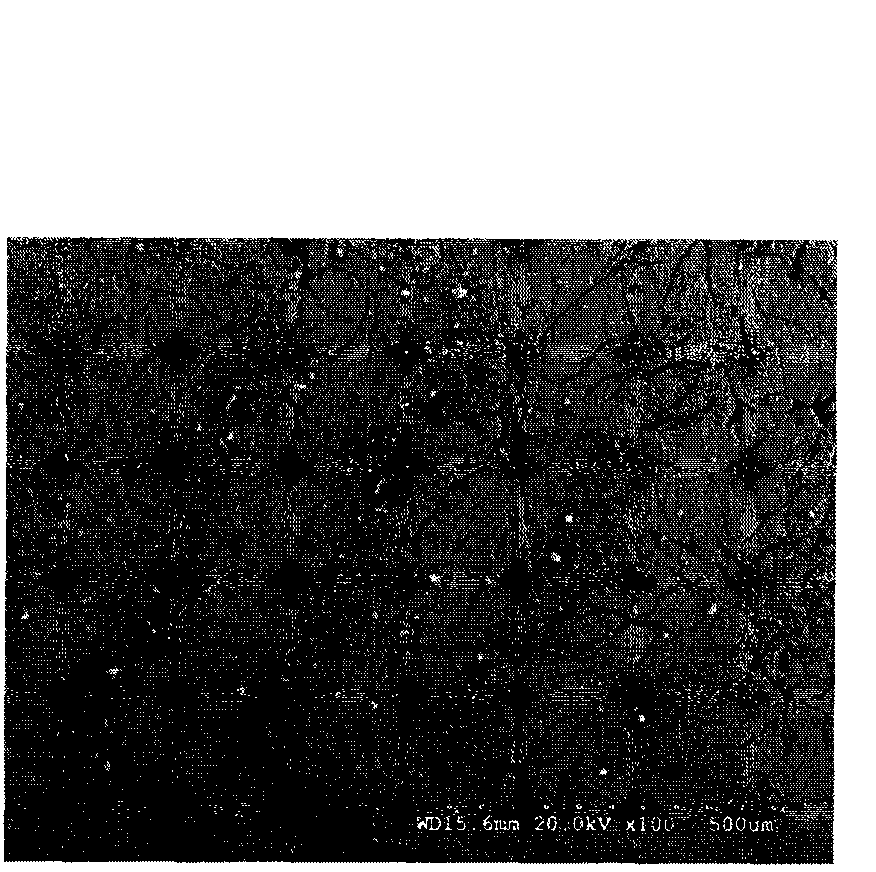

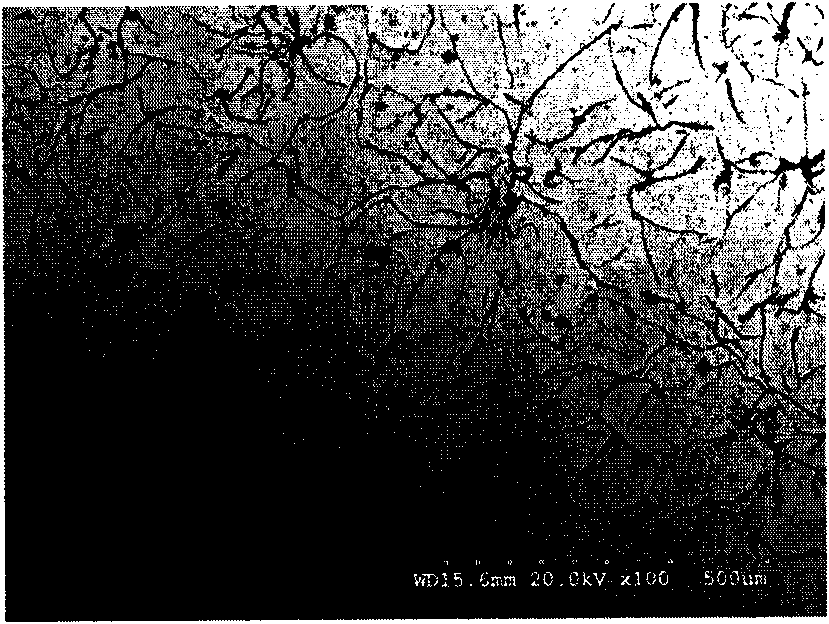

[0013] According to the particularity of iron cultural relics, the present invention screens out several industrial corrosion inhibitors that have been quite mature in industrial research and application, uses Z30 cast iron to simulate ancient cast iron samples, and compares the performance with the corrosion inhibitor of the present invention. Compare and describe in detail the mechanism of action of the corrosion inhibitor of the present invention.

[0014] In the corrosion of ancient ironware, Cl - It will greatly promote the electrochemical reaction of ironware, and at the same time, Cl - It can also accelerate the progress of local corrosion such as pitting corrosion, stress corrosion, intergranular corrosion and crevice corrosion, which is the biggest factor affecting the corrosion rate of ironware. Therefore, the present invention selects 3.5% NaCl solution as the corrosion environment, and compares and analyzes the corrosion inhibition performance of different corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com