Synchronous detection method of terrane crack distribution of base plate

A synchronous detection and fracture distribution technology, applied in surveying, earthwork drilling, wellbore/well components, etc., can solve problems such as long time required, limited popularization and application, and no hole collapse, to ensure timeliness and application scope. Wide and short measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

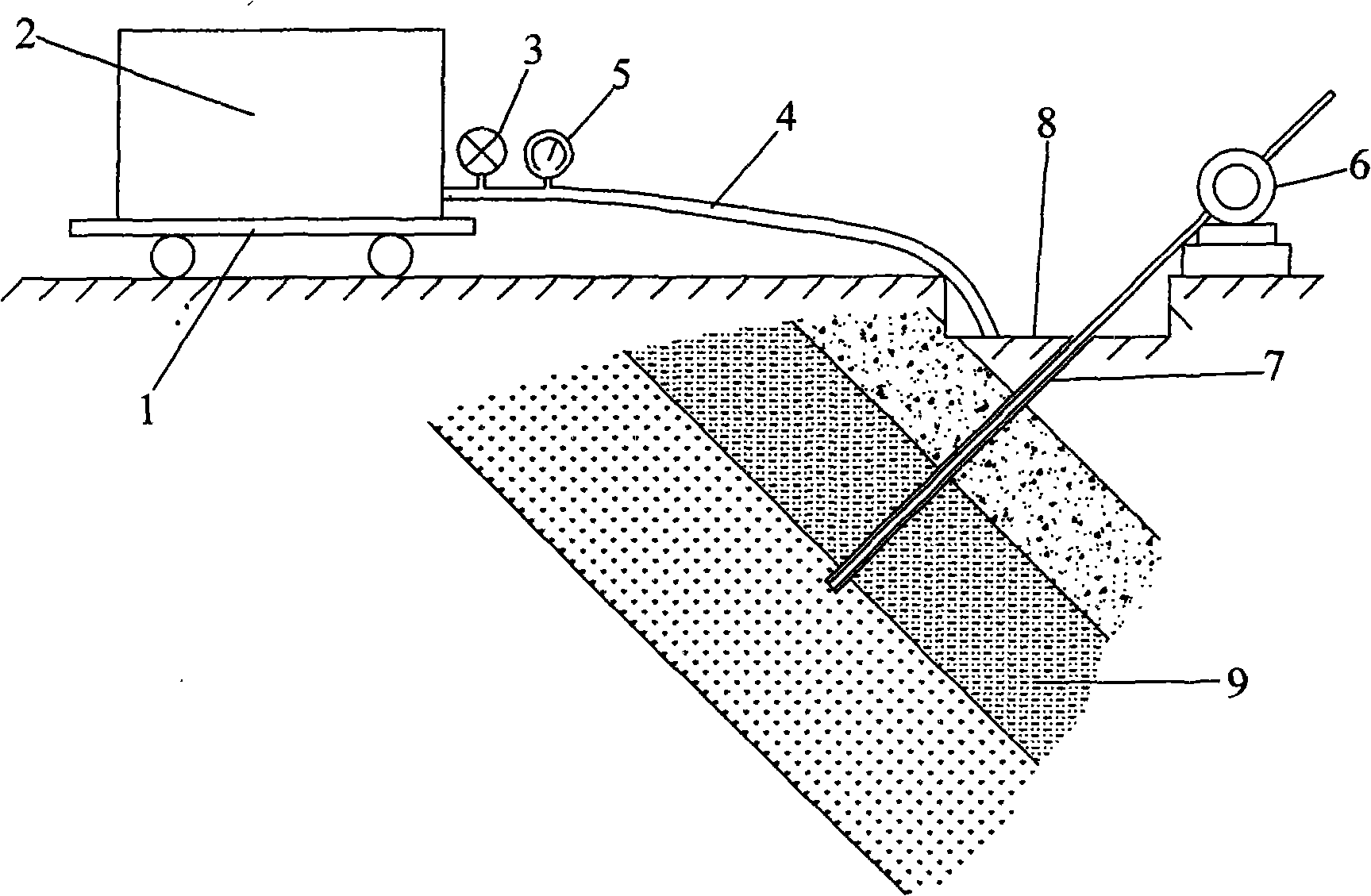

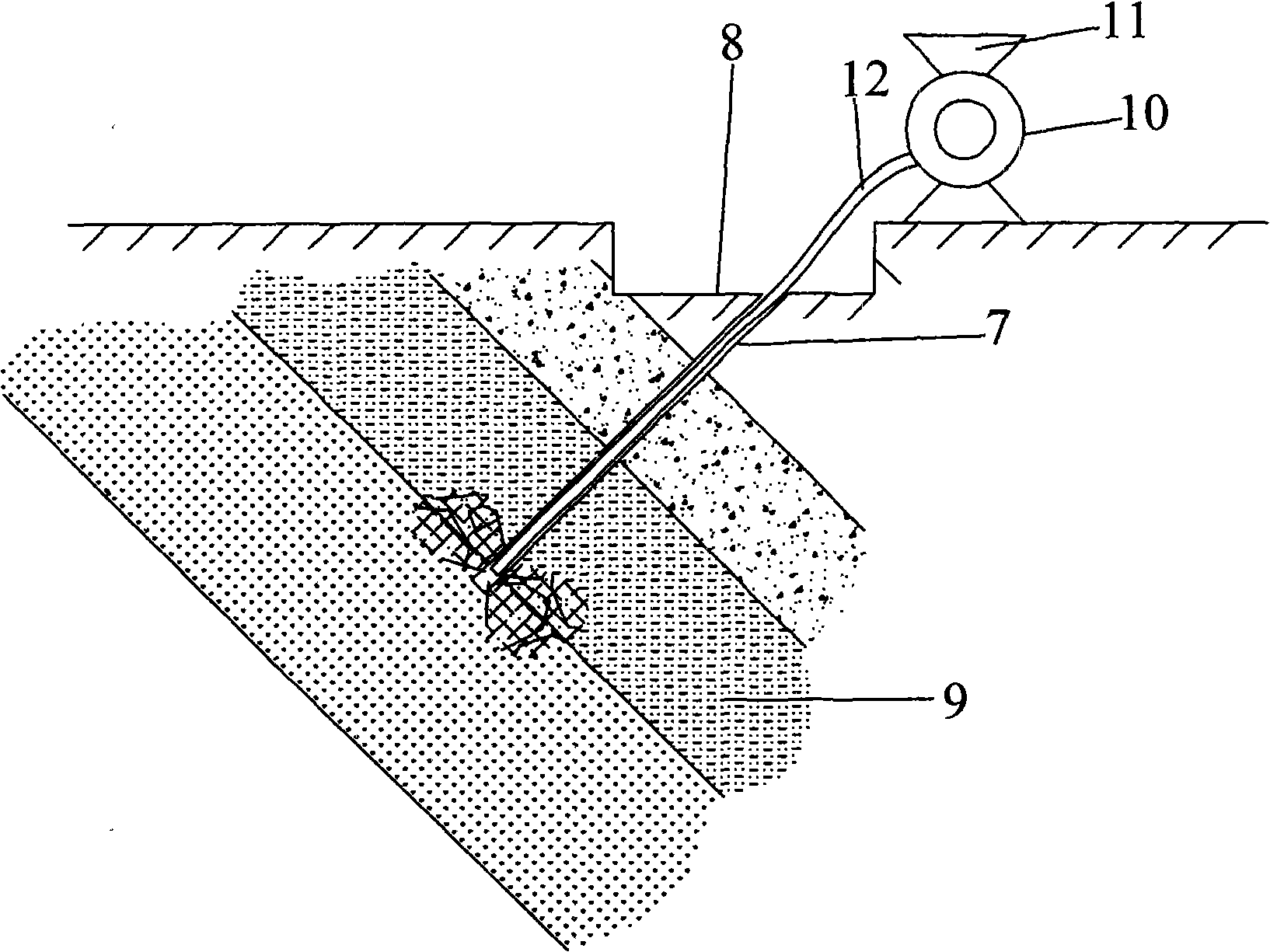

[0019] ①Drilling and testing equipment is installed in the underground roadway (see figure 1 ), including a tunnel drilling rig 6, a water tank 2 placed on the mine car 1 and a temporary pool 8, a water flow meter 5 and a water flow control switch 3 are connected in series on the outlet hose 4 of the water tank 2; pulp equipment (see figure 2 ), including mud pump 10, yellow mud irrigation 11 and mud delivery pipe 12.

[0020] ②Start the tunnel drilling machine 6, drill the drilling hole 7 along the direction perpendicular to the layer of the rock formation 9, turn on the water flow control switch 3 during the drilling process of the drilling hole 7, and let the water automatically flow into the drilling hole 7 through the water outlet hose 4 During drilling, water is injected while drilling, and the water volume is controlled to keep the flow level equal to the orifice.

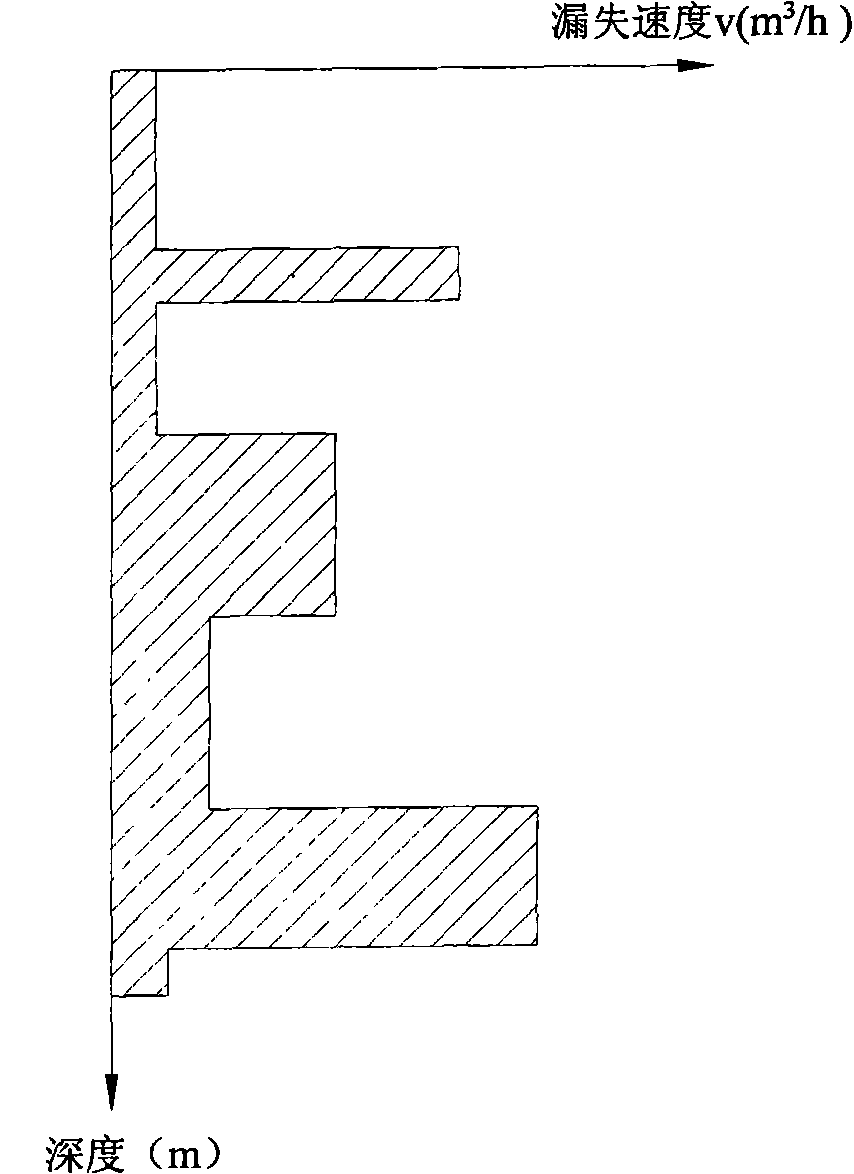

[0021] ③During the process of drilling while injecting water, record the location of the drill bit and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com