Electric tracing thermal insulation construction method for outdoor pipeline

A construction method and technology for external pipelines, applied in pipeline protection, pipeline heating/cooling, heat preservation, etc., can solve the problems of unsecured fire safety of buildings, freezing of outdoor pipelines, failure to meet the insulation requirements of outdoor pipelines, etc., and achieve construction The process design is reasonable, the construction steps are simple, and the effect of improving work efficiency and project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

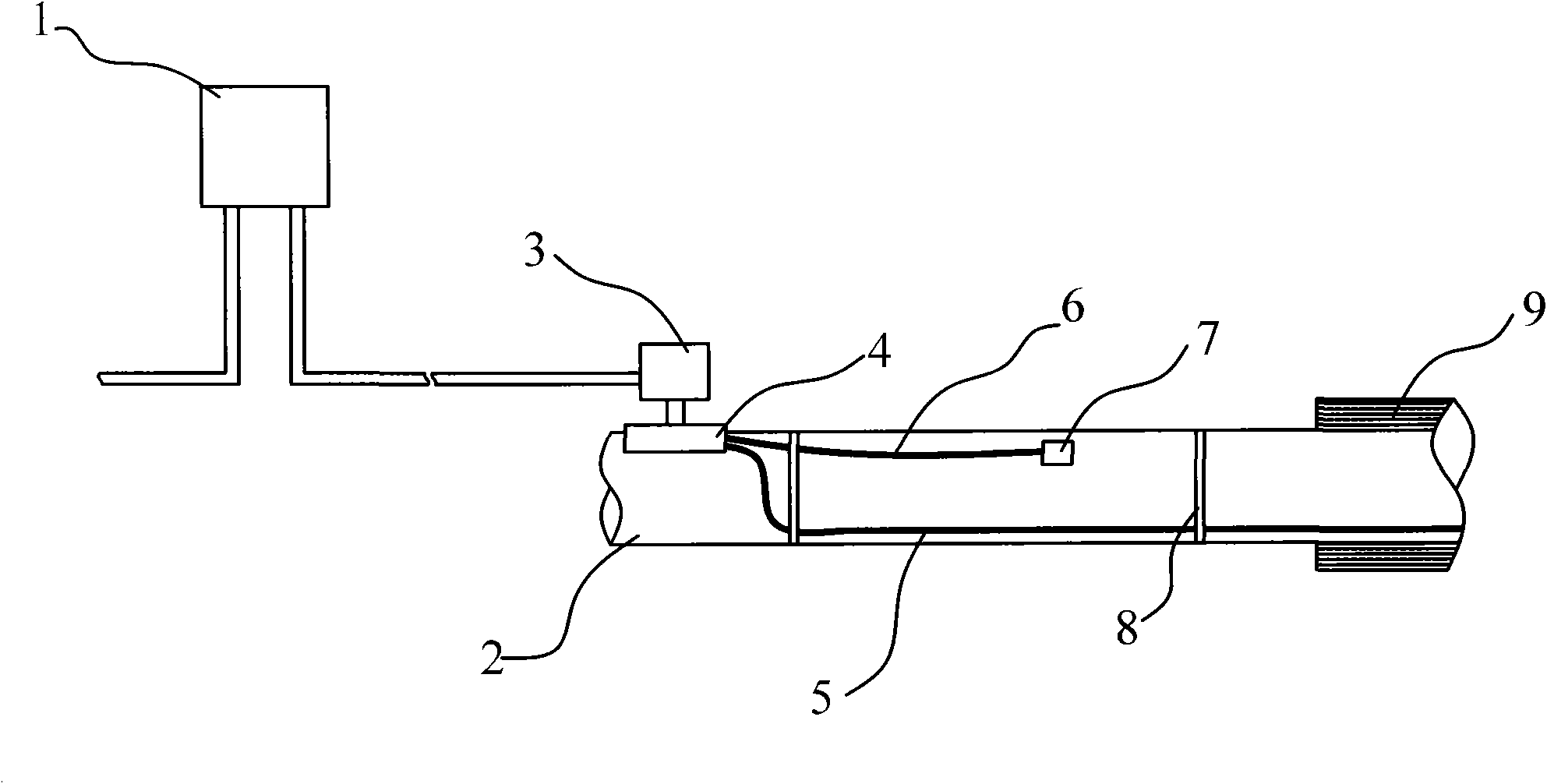

[0046] The utility model relates to a construction method for electric heat tracing and thermal insulation of outdoor pipelines. The electric heat tracing electric cable used is composed of conductive plastic, two parallel busbars plus an insulating layer, a metal shielding net, and an anti-corrosion jacket. Among them, the conductive plastic made of plastic plus conductive carbon particles through special processing is the core of heat generation. When the temperature around the electric heating belt is low, the micromolecules of the conductive plastic shrink, and the carbon particles are connected to form a circuit loop, and the electric heating belt starts to generate heat; when the temperature is high, the conductive plastic produces micromolecular expansion, and the carbon particles gradually separate, causing the circuit to be interrupted , the resistance rises, the electric heating belt automatically reduces the power output, and the calorific value is reduced. When the...

Embodiment 2

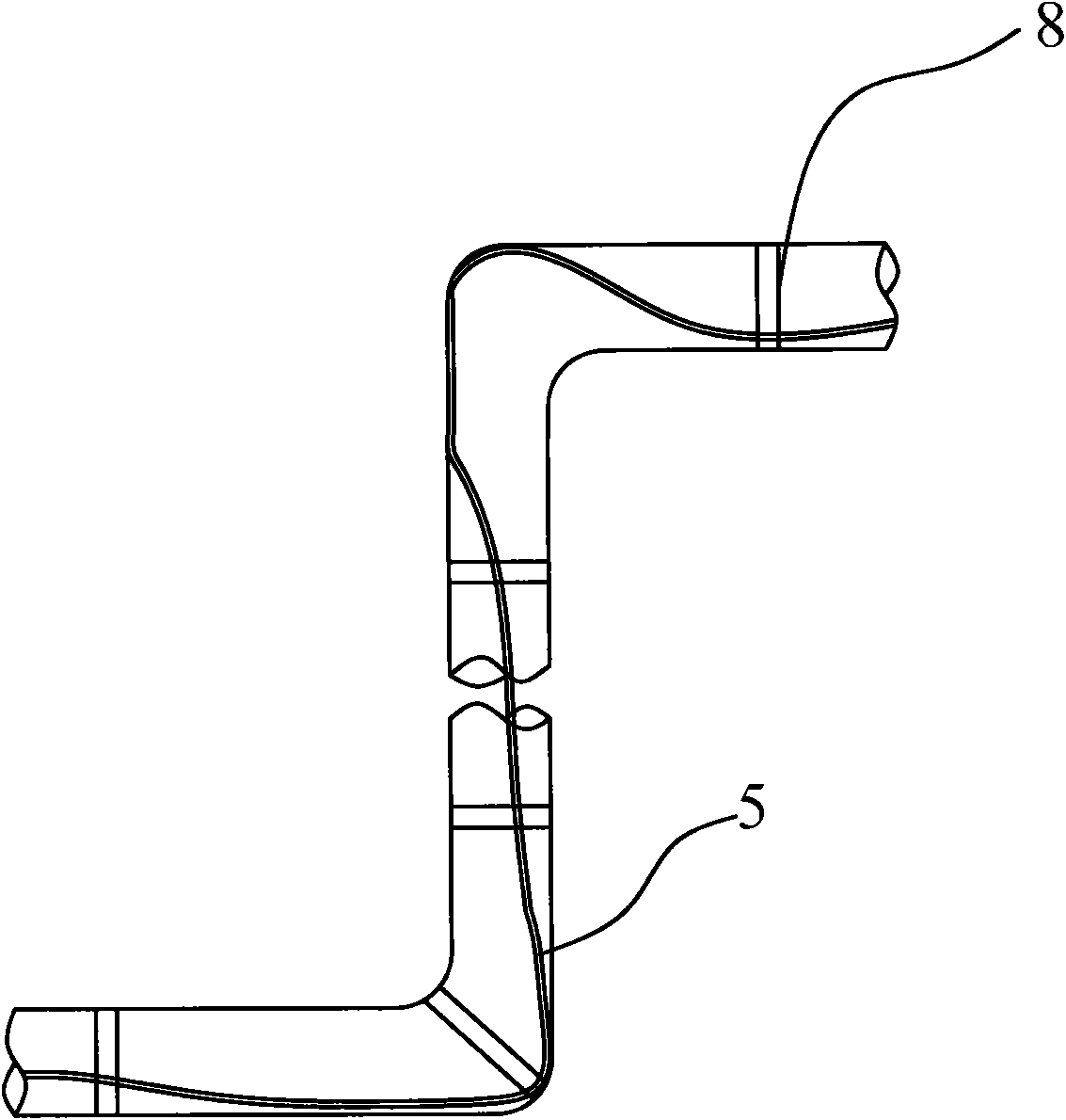

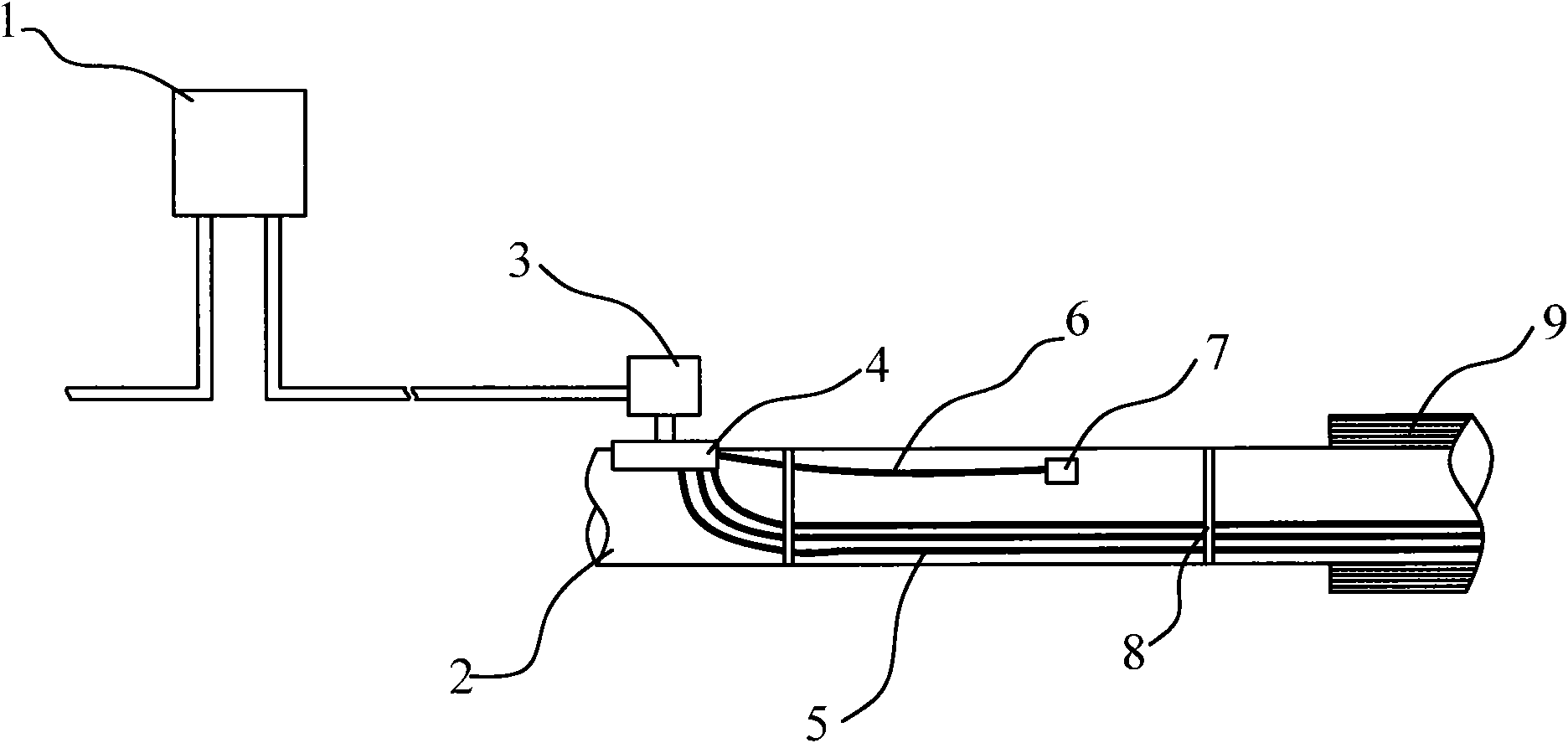

[0073] The only difference between embodiment 2 and embodiment 1 is that the winding coefficient in step 2 is 2.0; in step 301 of step 3, the length of each reserved electric heating belt at both ends of the outdoor pipeline is 2.0m; step 302 in step 3 , lay the electric heating cable under the 45° side of the straight pipe in a way that is close to the straight pipe, and paste it with aluminum foil tape every 1.0m; m electric heating cable; when the electric heating cable is laid to the flange, reserve 1.2m electric heating cable. The thickness of the heat insulation layer in step 4 is 80mm.

Embodiment 3

[0075] Embodiment 3 differs from Embodiment 1 and Embodiment 2 only in that: the winding coefficient in step 2 is 1.8; in step 301, the length of each reserved electric heating belt at both ends of the outdoor pipeline is 1.8m; the step of step 3 In 302, the electric heating cable is laid under the 45° side of the straight pipe in a way that is close to the straight pipe, and is pasted and fixed with aluminum foil tape every 0.8m; 0.8m electric heating cable; when the electric heating cable is laid to the flange, reserve 1.2m electric heating cable. The thickness of the thermal insulation layer in step 4 is 70mm.

[0076] In the present invention, before electric heating construction, the spurs and sharp corners on the outer wall of the straight pipe and the pipe connector are firstly filed off, and the sharp parts are polished to make the outer wall of the straight pipe and the pipe connector smooth; the purpose of doing this is to make the straight The outer wall of the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com