System for producing liquefied natural gas by utilizing liquid nitrogen cold energy

A technology for liquefied natural gas and natural gas pipelines, applied in the system field of producing liquefied natural gas, can solve the problems of complex design, high cost, increased equipment and process complexity, etc., and achieve the effect of increasing production and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

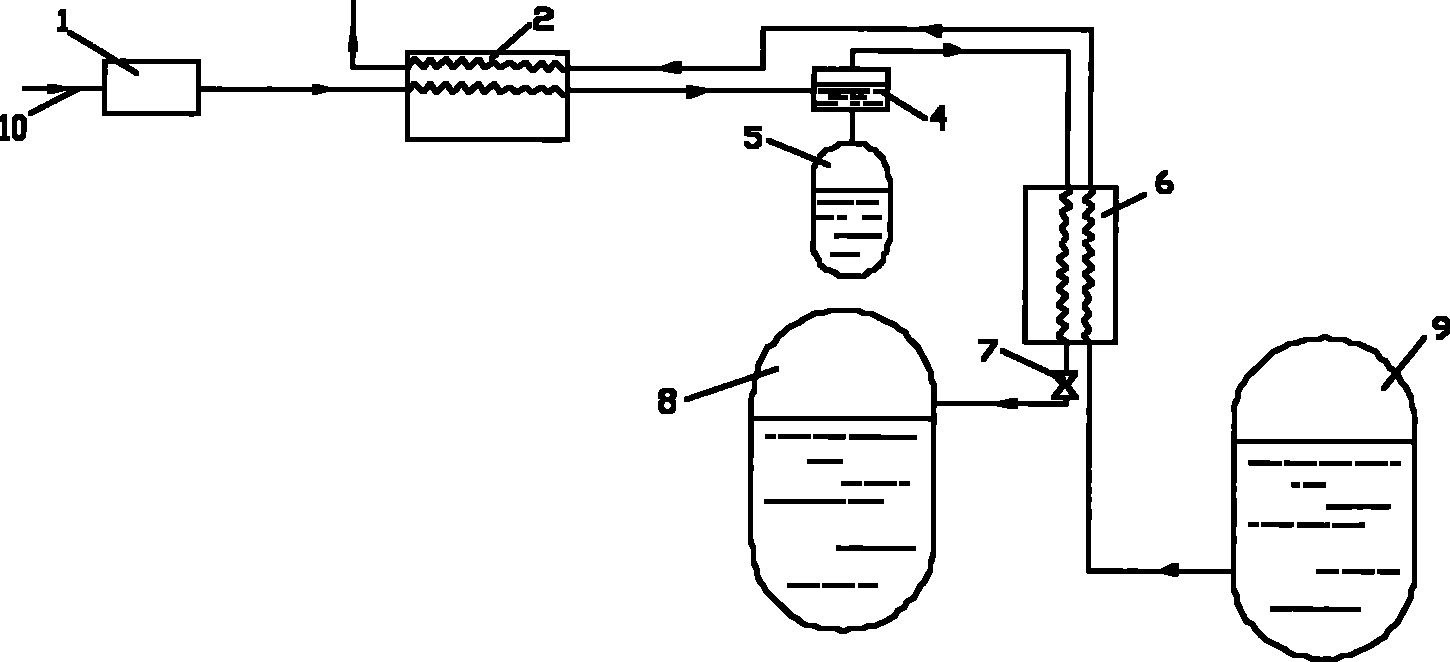

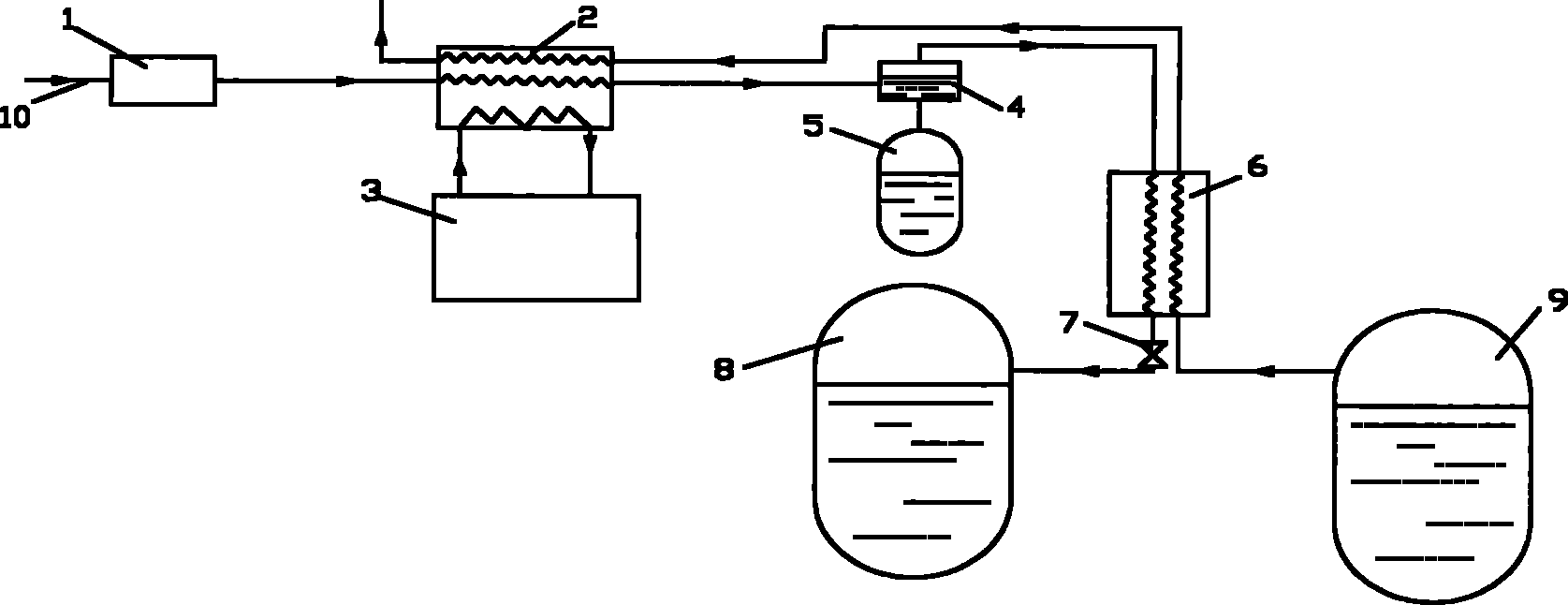

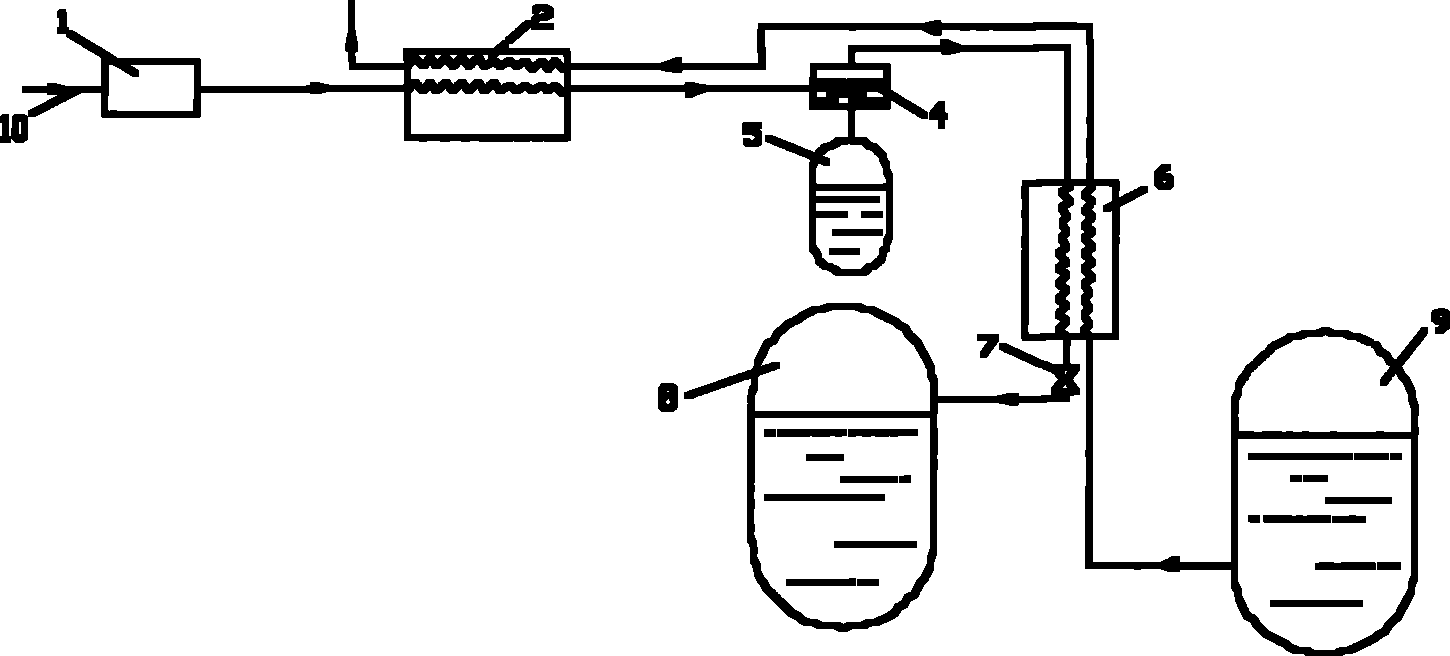

[0017] As shown in the figure, the system for producing liquefied natural gas by using the cold energy of liquid nitrogen includes purification equipment 1, pre-cooling heat exchanger 2, gas-liquid separator 4, low-temperature storage tank 5, main heat exchanger 6, throttle valve 7, Cryogenic storage tank 8, liquid nitrogen storage tank 9 and natural gas pipeline 10; purification equipment 1 and the thermal fluid passage of precooling heat exchanger 2, gas-liquid separator 4, the thermal fluid passage of heat exchanger 6, throttle valve 7 and The low-temperature storage tanks 8 are connected in sequence, the gas-liquid separator 4 is connected with the low-temperature storage tank 5, the liquid nitrogen storage tank 9 is connected with the cold fluid channel of the pre-cooling heat exchanger 2 through the cold fluid channel of the main heat exchanger 6, and the purification equipment 1 Connected with natural gas pipeline 10.

[0018] The pre-cooling heat exchanger 2 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com