Osmotic pressure measuring device for high water pressure test system

A test system, high-pressure water pressure technology, applied in the direction of measuring devices, measuring fluid pressure, permeability/surface area analysis, etc., can solve the problem of failure to achieve effective measurement of osmotic pressure, failure of osmotic pressure measurement of osmotic pressure holes, construction Quality is difficult to guarantee and other issues, to avoid the failure of osmotic pressure measurement, simple and reliable structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

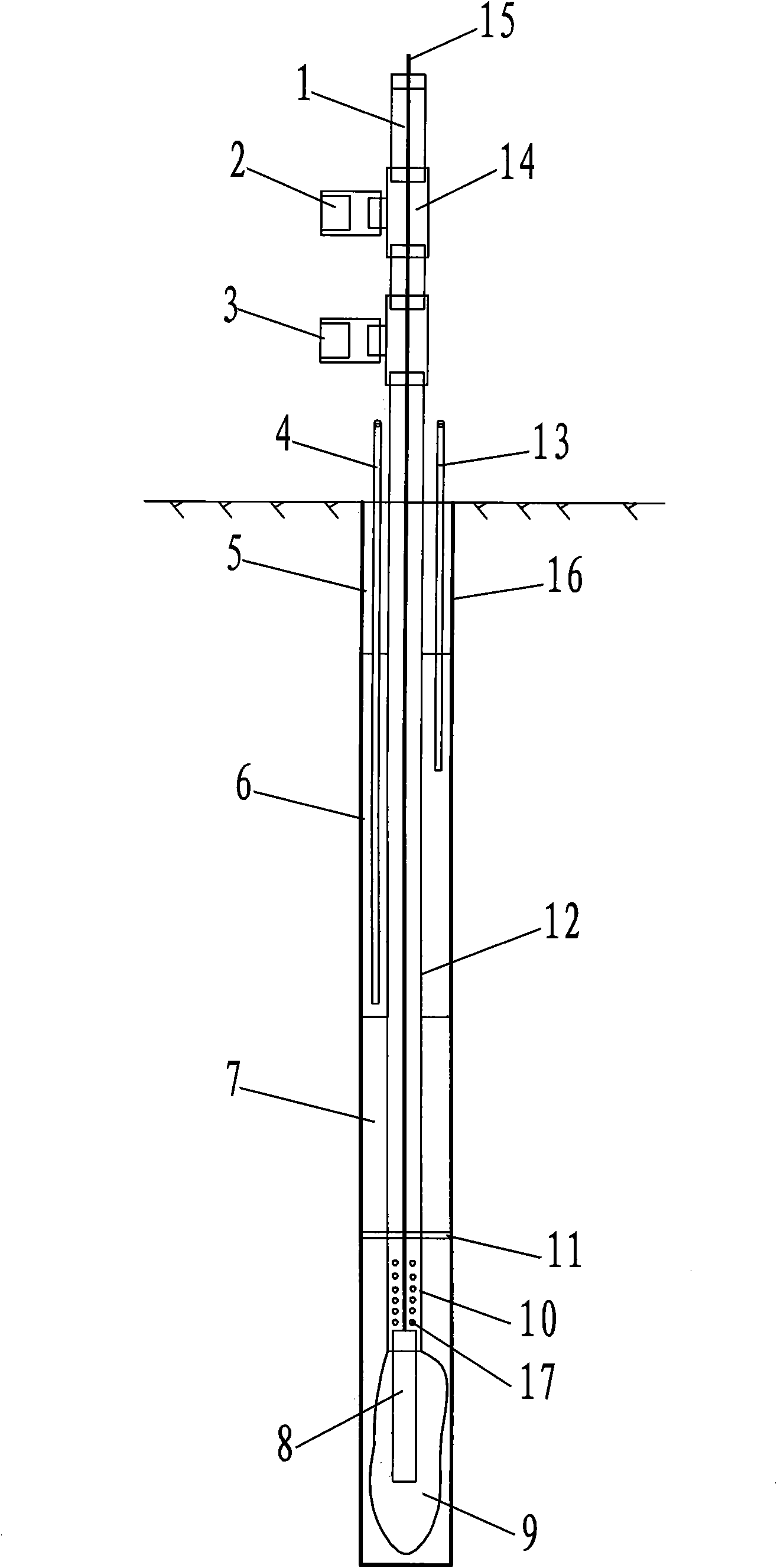

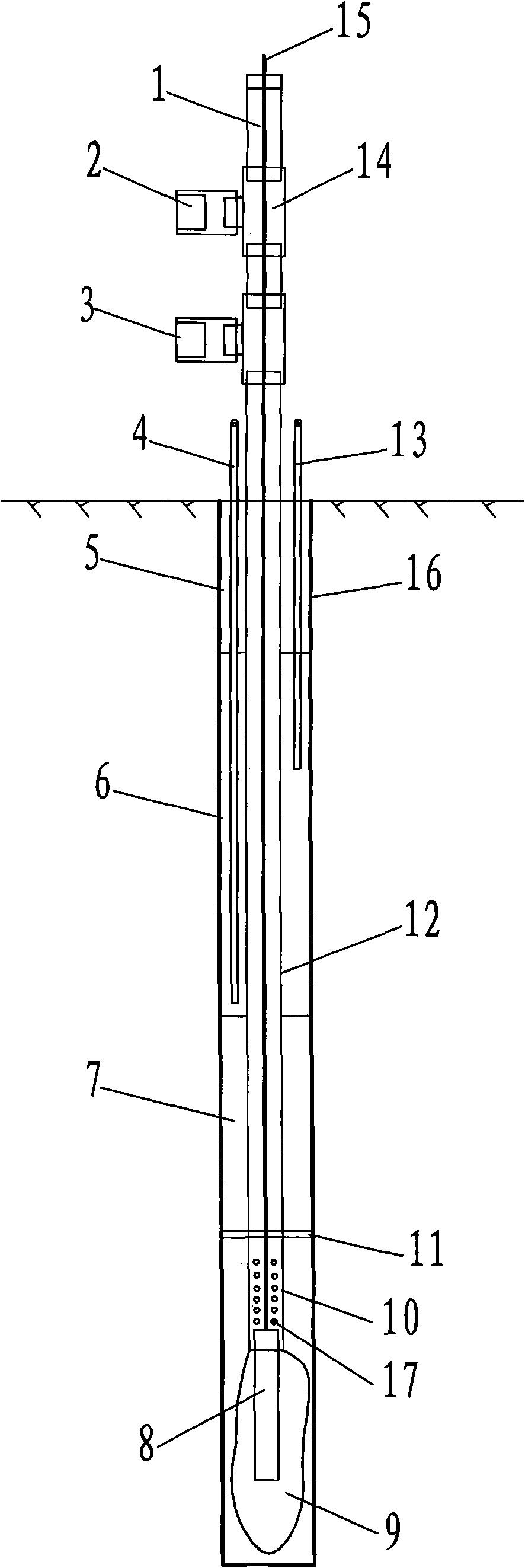

[0016] Such as figure 1 As shown, the present invention includes a seepage hole 16 opened in the rock body, and one end of a seamless steel pipe 12 stretches into the bottom of the seepage hole 16 . A piezometer 8 is fixed on the bottom of the seamless steel pipe 12, and its cable 15 passes through the seamless steel pipe 12 and stretches out of the seepage hole 16, and the outer surface of the piezometer 8 is covered with a protective sand bag 9. Above the seamless steel pipe 12 one end of the fixed piezometer 8, a flower pipe section 10 with a length of 20 cm is set, that is, the flower pipe section 10 is provided with a water hole 17 that runs through inside and outside, so that the water body inside the seamless steel pipe and outside the piezometer 8 connected. A rubber clapboard 11 is set on the outer side of the flower tube section 10 of the seamless steel pipe at 15 cm above, and the water-stop kelp 7 is bound up from the rubber clapboard 11 within the range of 100 cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com