Manufacturing method of full tantalum shell tantalum electrolytic capacitor and capacitor

A technology for tantalum electrolytic capacitors and a manufacturing method, which is applied to electrolytic capacitors, capacitors, capacitor terminals, etc., can solve the problems of large space required, large volume, and unfavorable miniaturization of electronic equipment, so as to reduce the installation volume and meet the requirements of charging and discharging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

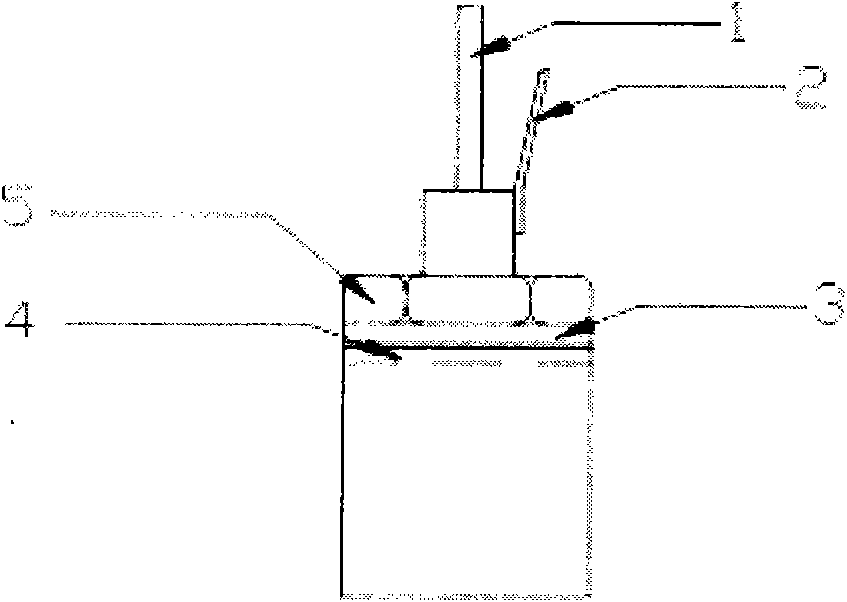

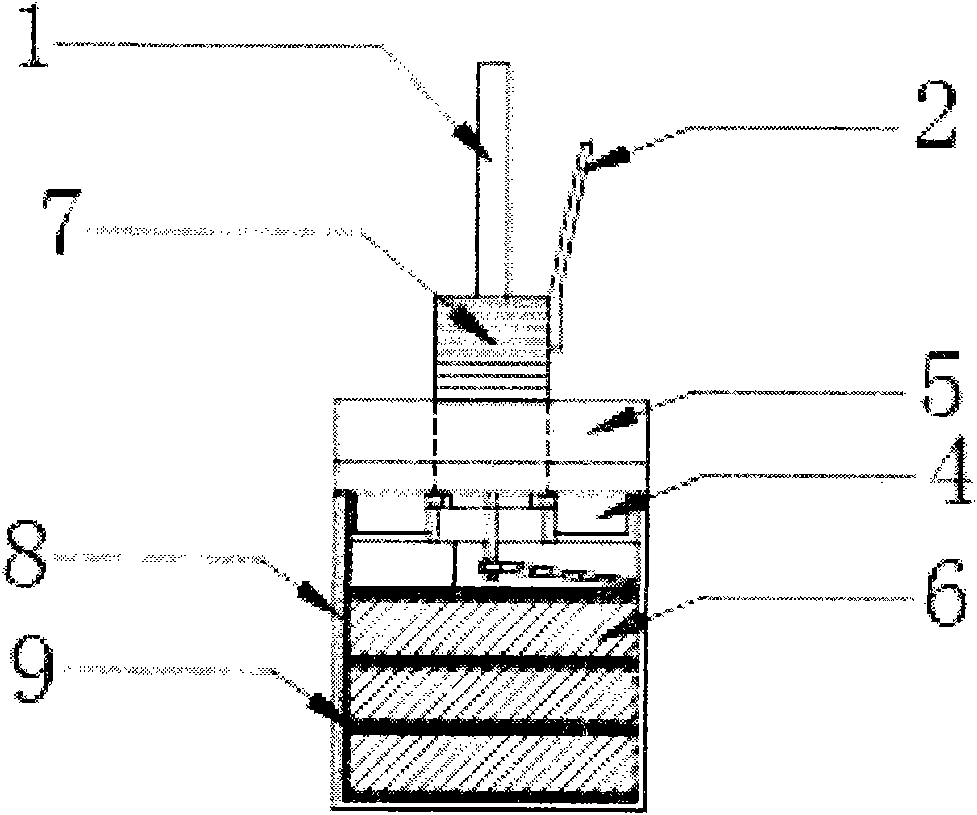

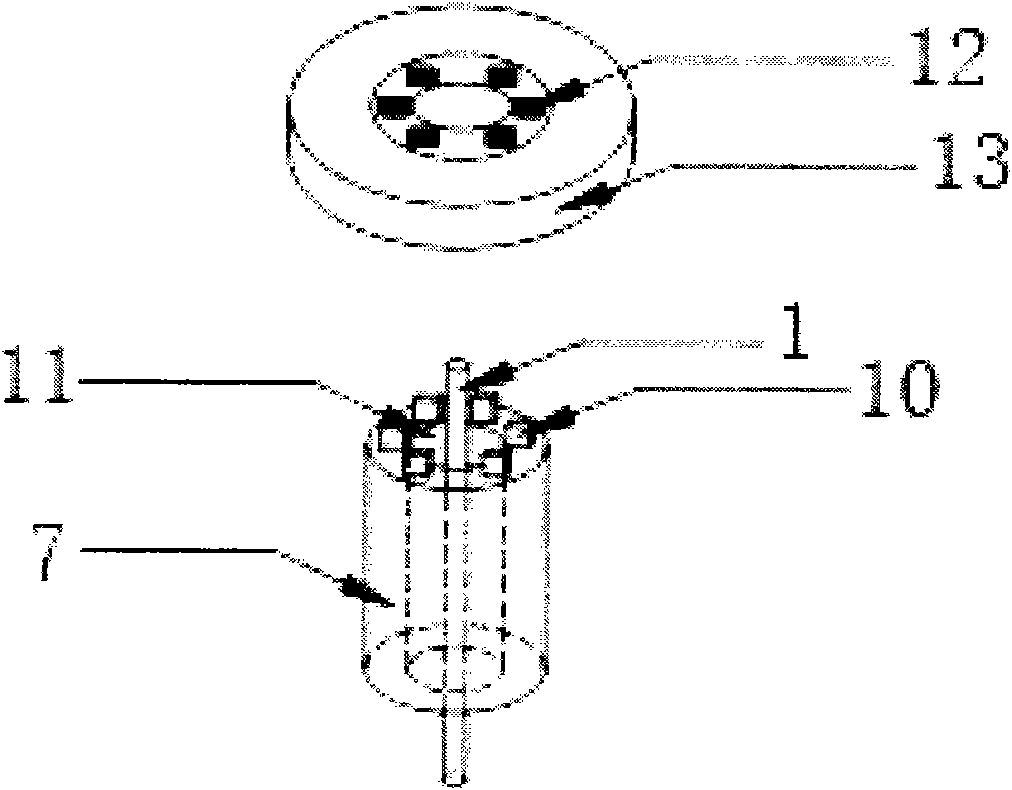

[0016] A method for manufacturing a tantalum electrolytic capacitor with a full tantalum shell, which is packaged in a cylindrical metal tantalum shell, has an airtight structure, and is a single capacitor. The capacitor is a capacitor that uses bolts as a mounting method. First, prepare all-tantalum insulators with bolts. The bolts are made of metal tantalum tubes, with tantalum wires passing through in the middle, and insulating glass powder is sintered between the tantalum wires and tantalum bolts for insulation. First, put the bolts upside down on the fixture, and then Fasten the tantalum cover with six small holes on the six protruding pins of the bolt, and use a laser welding machine or argon arc welding machine to weld and fuse the small holes of the tantalum cover with the six pins on the bolt to complete the whole process. Fabrication of tanta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com