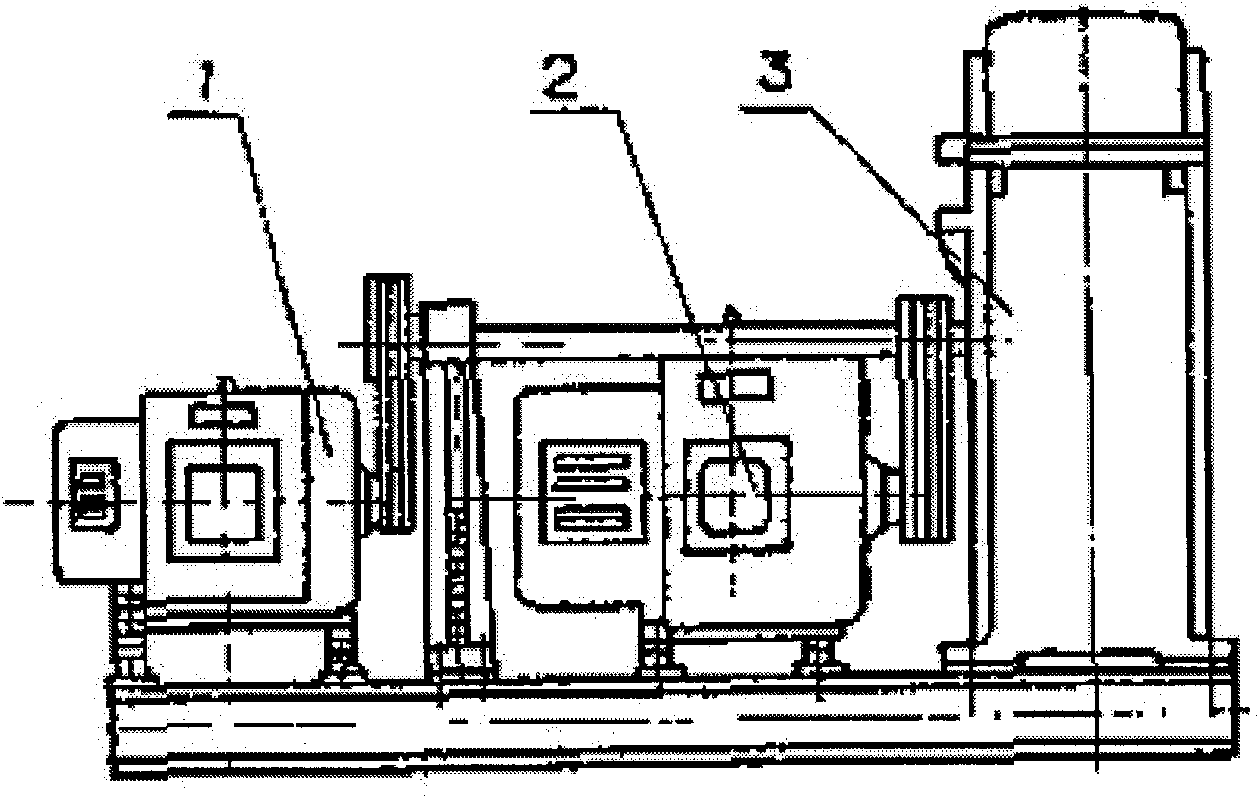

Tube blank feeding system of multiroll large-caliber cold pilgering mill

A cold-rolled pipe mill and large-diameter technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of uneven feeding, reduce auxiliary time, improve production efficiency, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

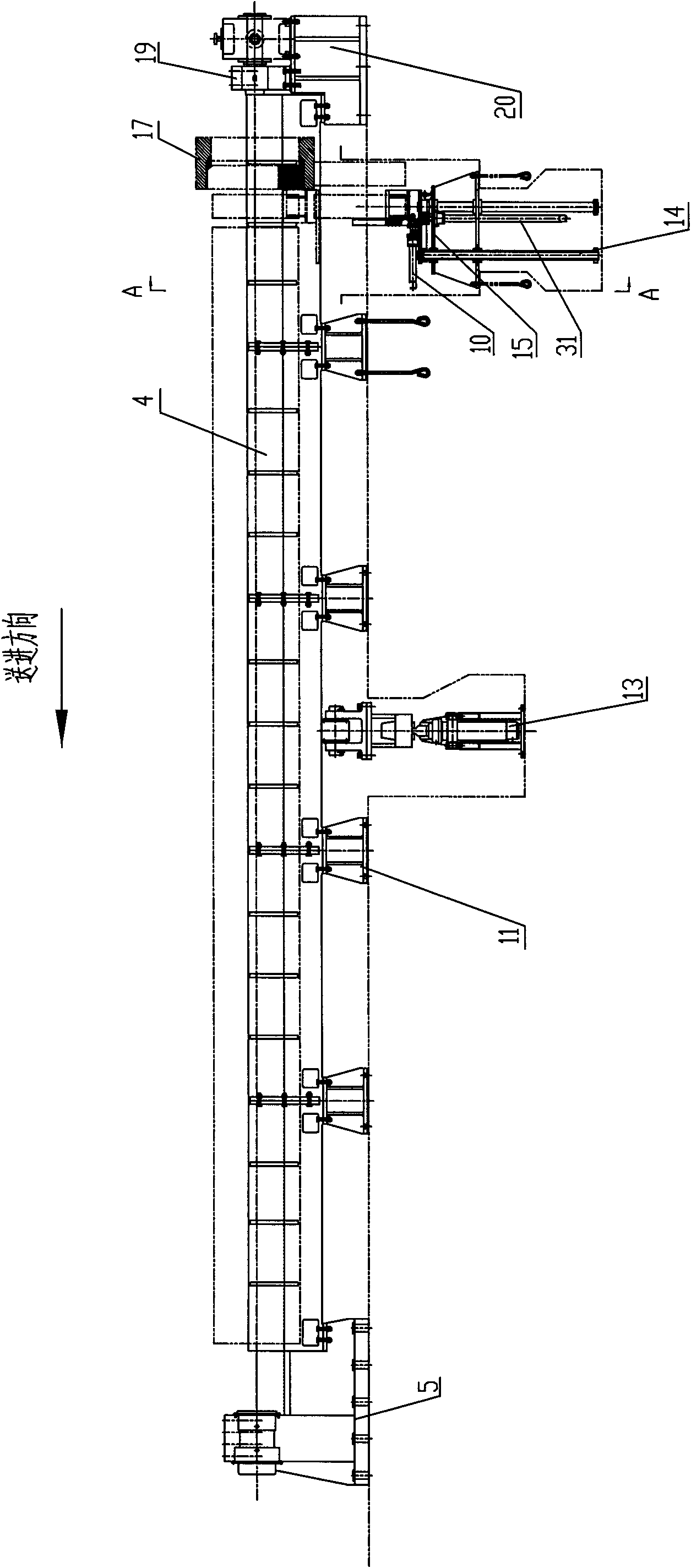

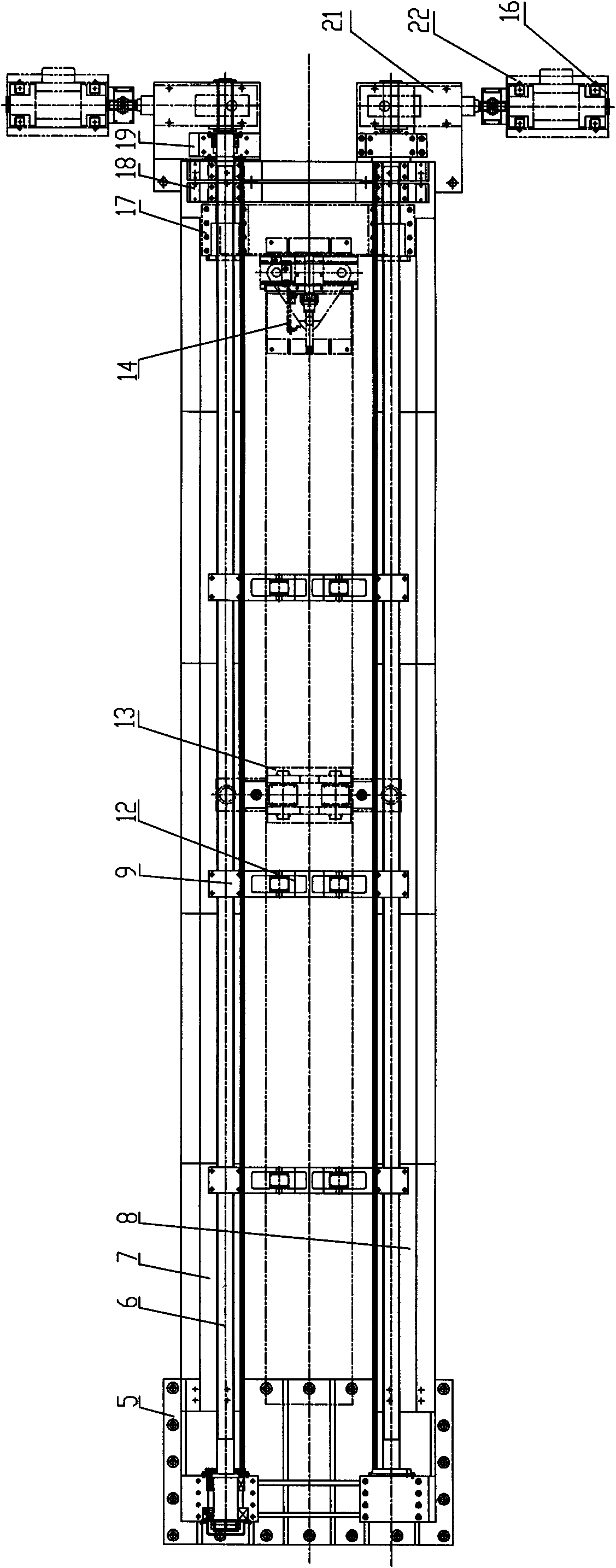

[0024] Such as figure 2 , 3 , 4, 5, 6, 7, and 8 are the billet feeding system of the multi-roller large-diameter cold-rolled pipe mill, including the bed 4, and the bed 4 includes two screw front supports 5 arranged at the front end And the two bases 20 that are arranged on the rear end, the two bases 20 are also fixedly connected to the rear support 19 of the leading screw respectively. The bed 4 also includes a left crossbeam 8 and a right crossbeam 7 , the two ends of the left crossbeam 8 and the right crossbeam 7 are respectively fixedly connected with the corresponding screw front support 5 and the base 20 . The bottom of the left beam 8 and the right beam 7 is fixedly connected with the beam support 11 .

[0025] Lead screw 6 is arranged in the leading screw support 5 and the leading screw rear support 19 on the same side, and two sets of lead screw brackets 18 are arranged at the rear ends of the two lead screw 6, and the rear ends of each lead screw 6 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com