High-efficiency compact type solid state high-frequency induction welder

A high-frequency welding machine, compact technology, applied in the direction of high-frequency current welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large high-frequency interference factors, affecting welding quality, and low equipment efficiency, so as to reduce equipment volume, improve equipment efficiency, and reduce the effect of long-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

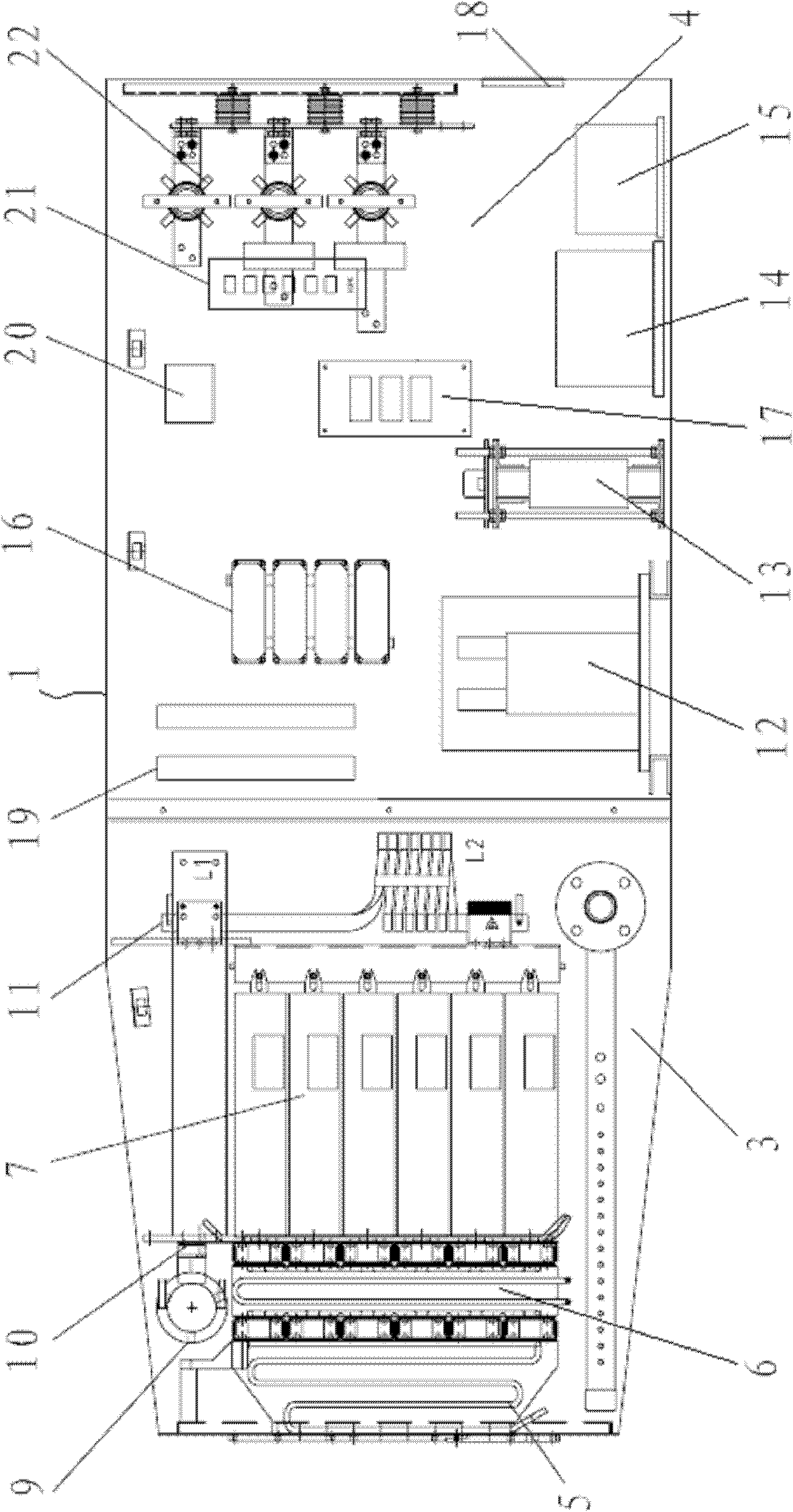

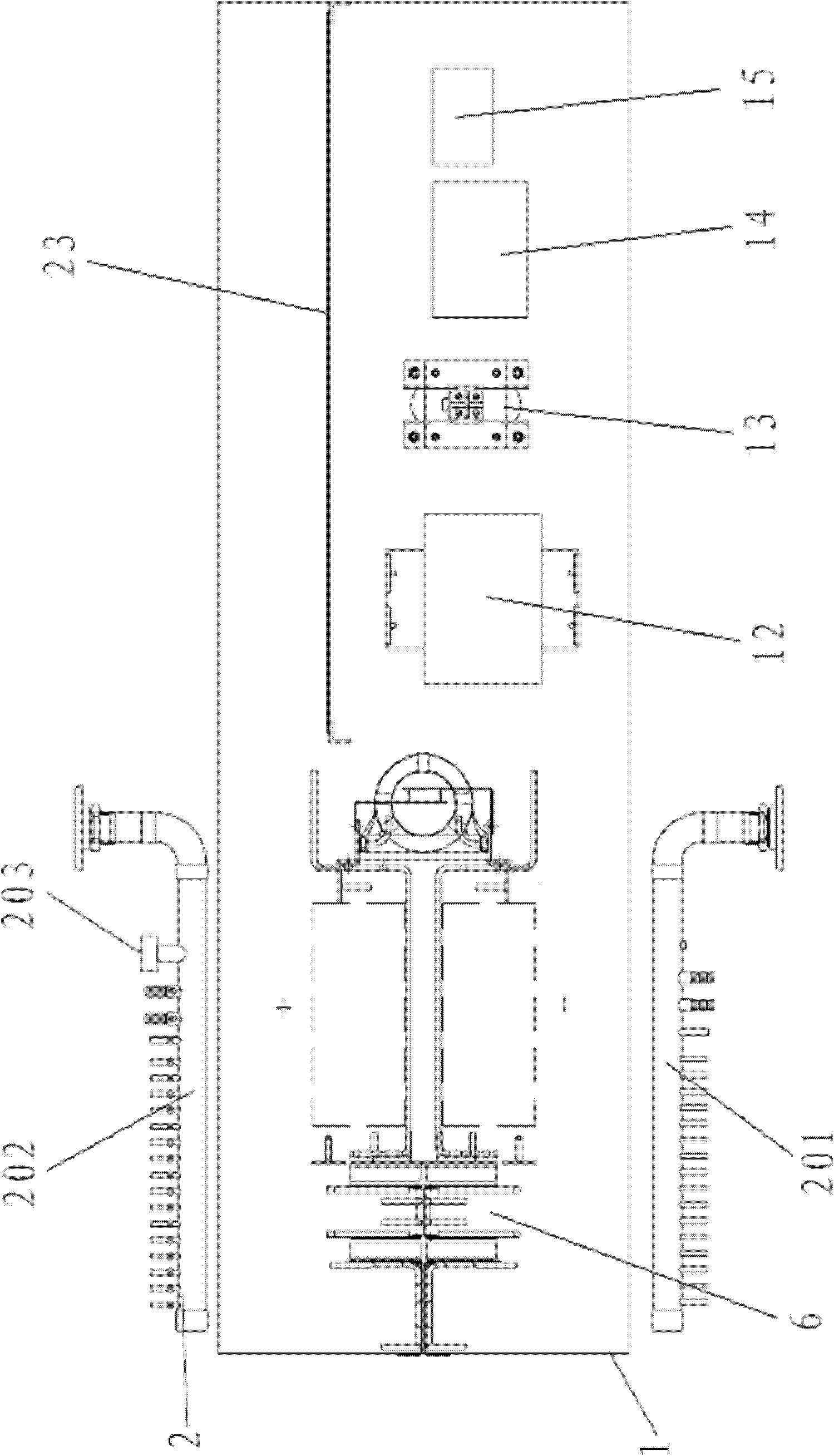

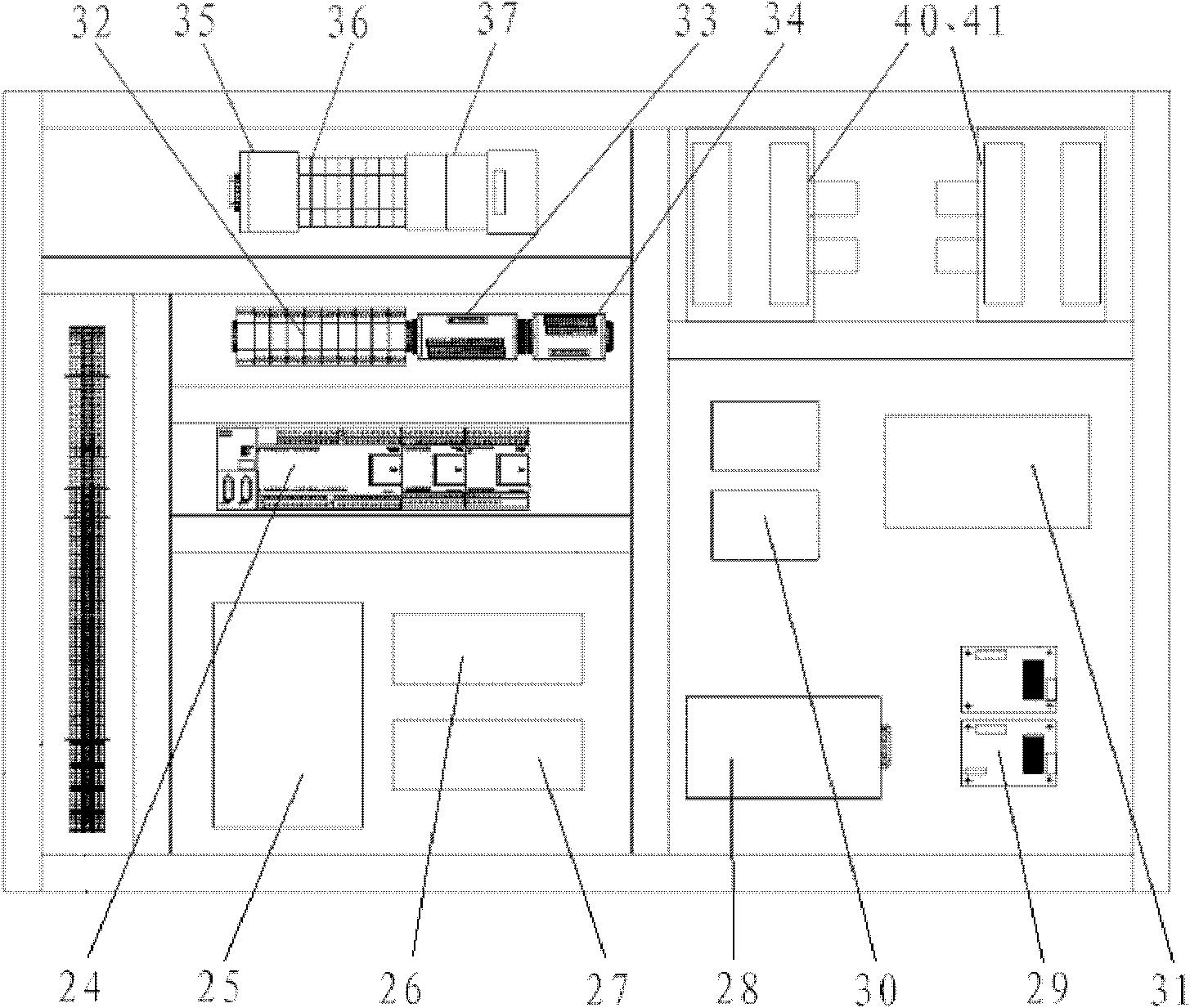

[0028] see figure 1 and figure 2 , the high-efficiency and compact solid-state high-frequency welding machine of the present invention includes a power supply cabinet 1 and a water system 2. The power supply cabinet is an integrated type that integrates power supply, rectification and inverter, wherein: the cabinet body of the power supply cabinet 1 includes a left side cabinet and right cabinet.

[0029] The left cabinet 3 mainly forms the inverter function, and is responsible for inverting the DC signal into a high-frequency signal output. The layout of the electrical components in the left cabinet 3 is as follows: from left to right, there is a tank circuit capacitor assembly 5 and a double-row capacitor row. Component 6, a number of high-frequency power modules 7 and a pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com