Process for producing rotary embossing plate

A production process, a technology of round pressing and rounding, applied in the field of production technology of embossed plates, can solve the problems such as the quality of embossed plates, the adverse effects of precision, the difficulty of controlling the corrosion range of liquid medicine, and the increase of production processes, etc., so as to achieve clear product patterns, The effect of strong unevenness and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

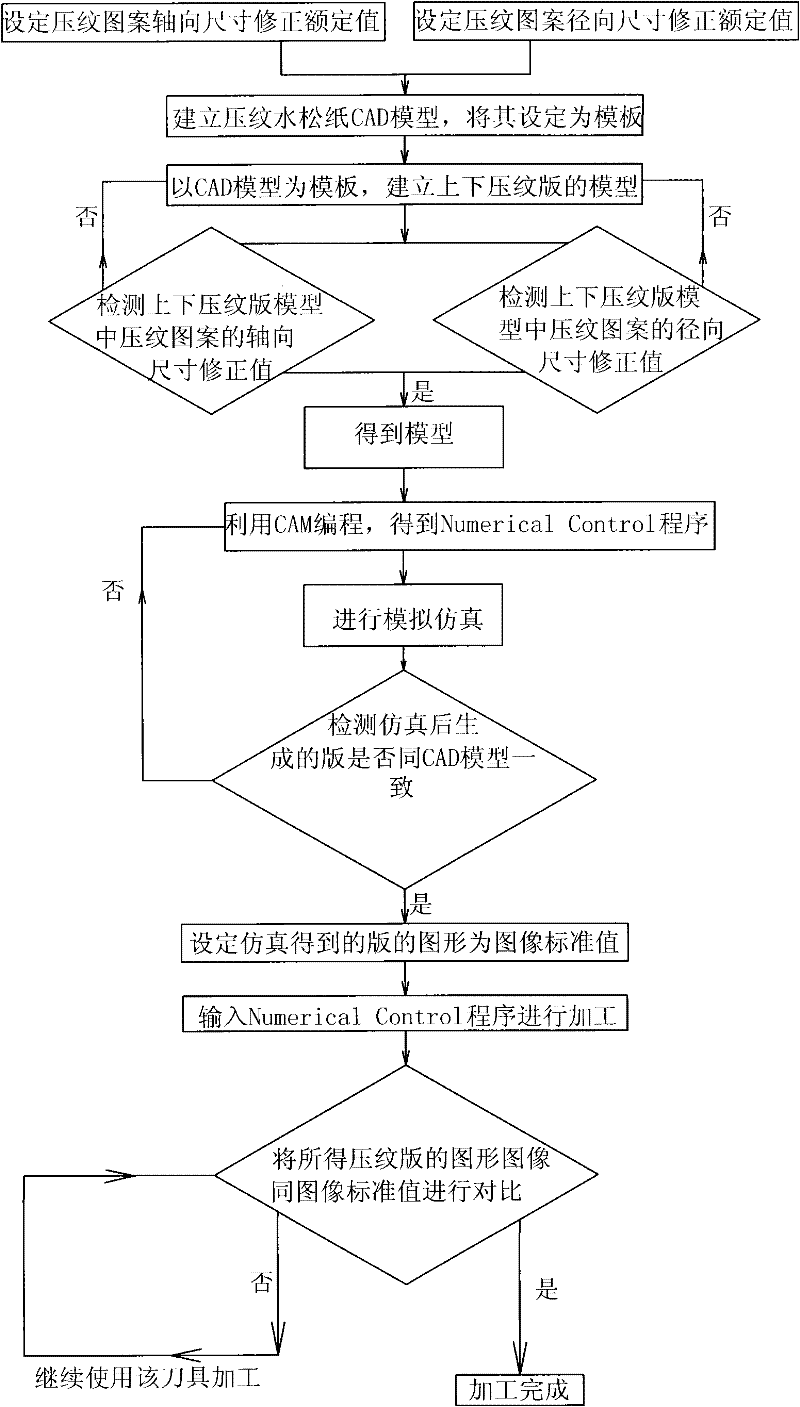

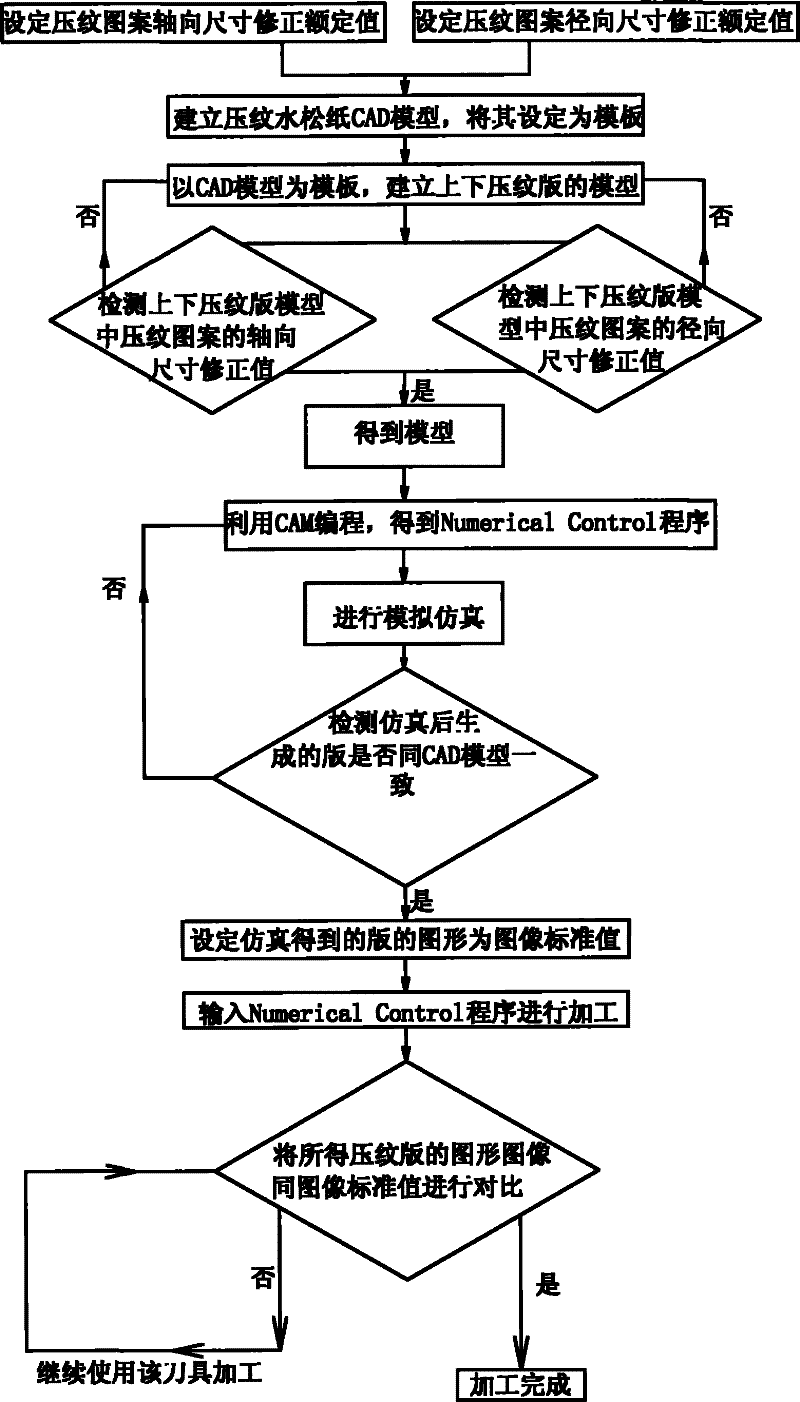

[0022] This embodiment is to prepare an embossed plate with a cubic embossed pattern, and the specific steps are as follows:

[0023] A production process for circularly embossed plates is characterized in that it is manufactured according to the following production process, and the specific steps are:

[0024] a. The superposition value of the installation error of the set plate and the equipment error of the embossing machine is used as the rated value of the axial dimension correction of the embossed pattern of the plate, and the rated value is 75 μm;

[0025] b. Set the processing error of the CNC machine tool and the shrinkage rate of the raw material as the rated value of the radial dimension correction of the embossed plate pattern of the plate, and the rated value is 80 μm;

[0026] c. Establish a CAD model for producing tipping paper with cubic embossed patterns, and set it as a template;

[0027] d. Using the model in step c as a template, establish a CAD model of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com