Non-contact type automobile electronic throttle pedal

An accelerator pedal, automotive electronics technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as abnormal fuel loss, sensor failure, affecting personal and property safety, etc., to solve fuel waste, ensure linear accuracy and stability performance, ensure high life and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

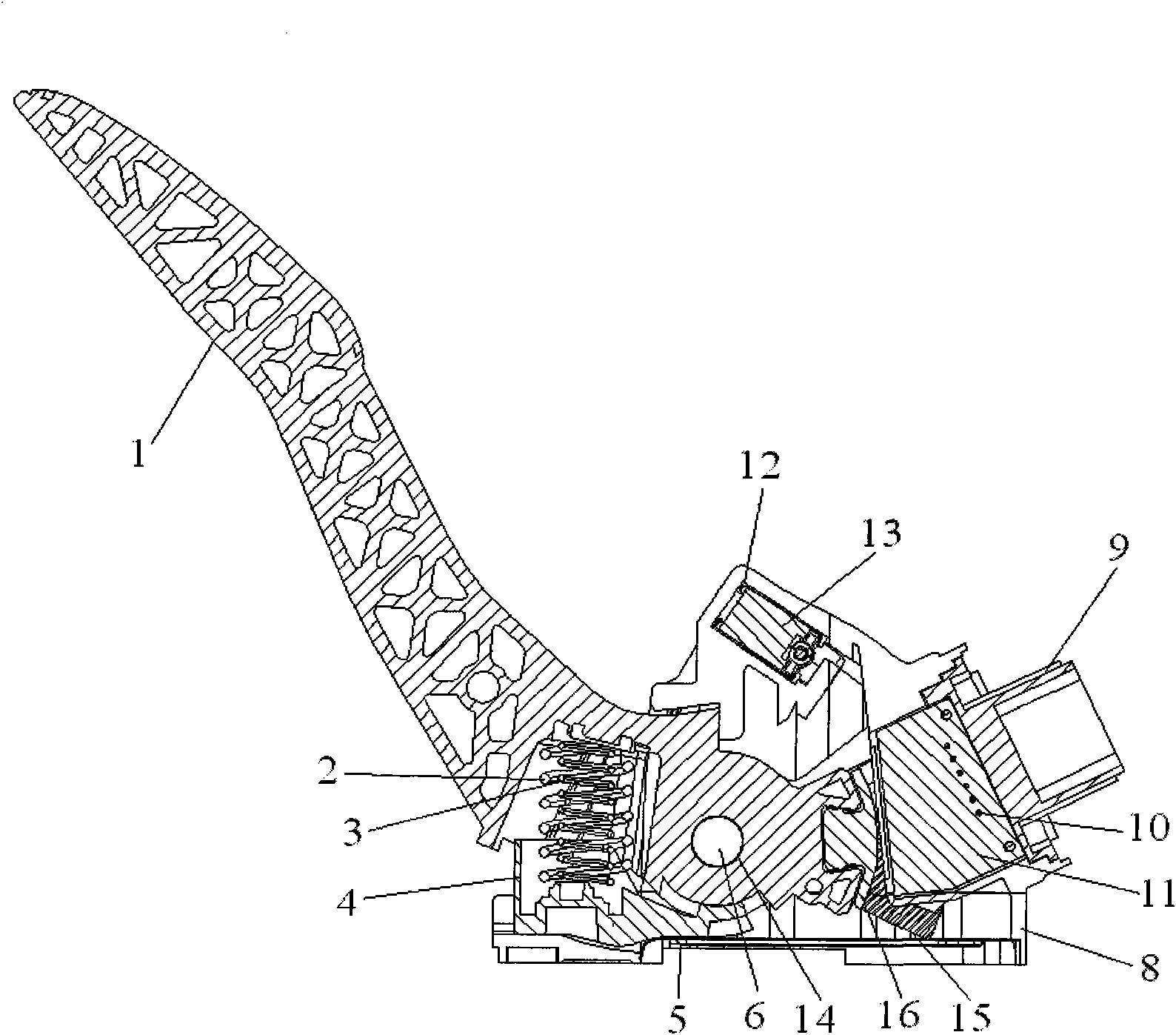

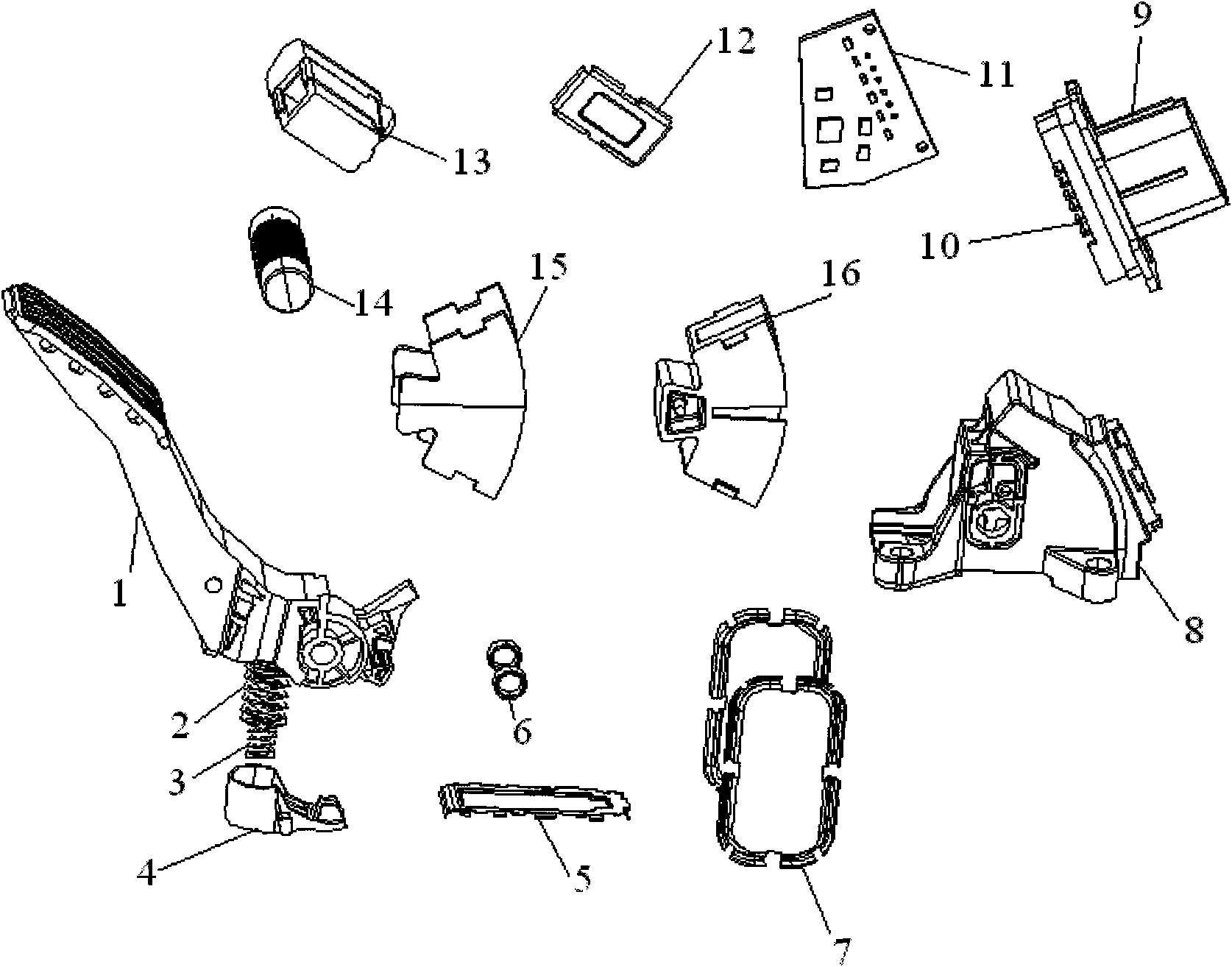

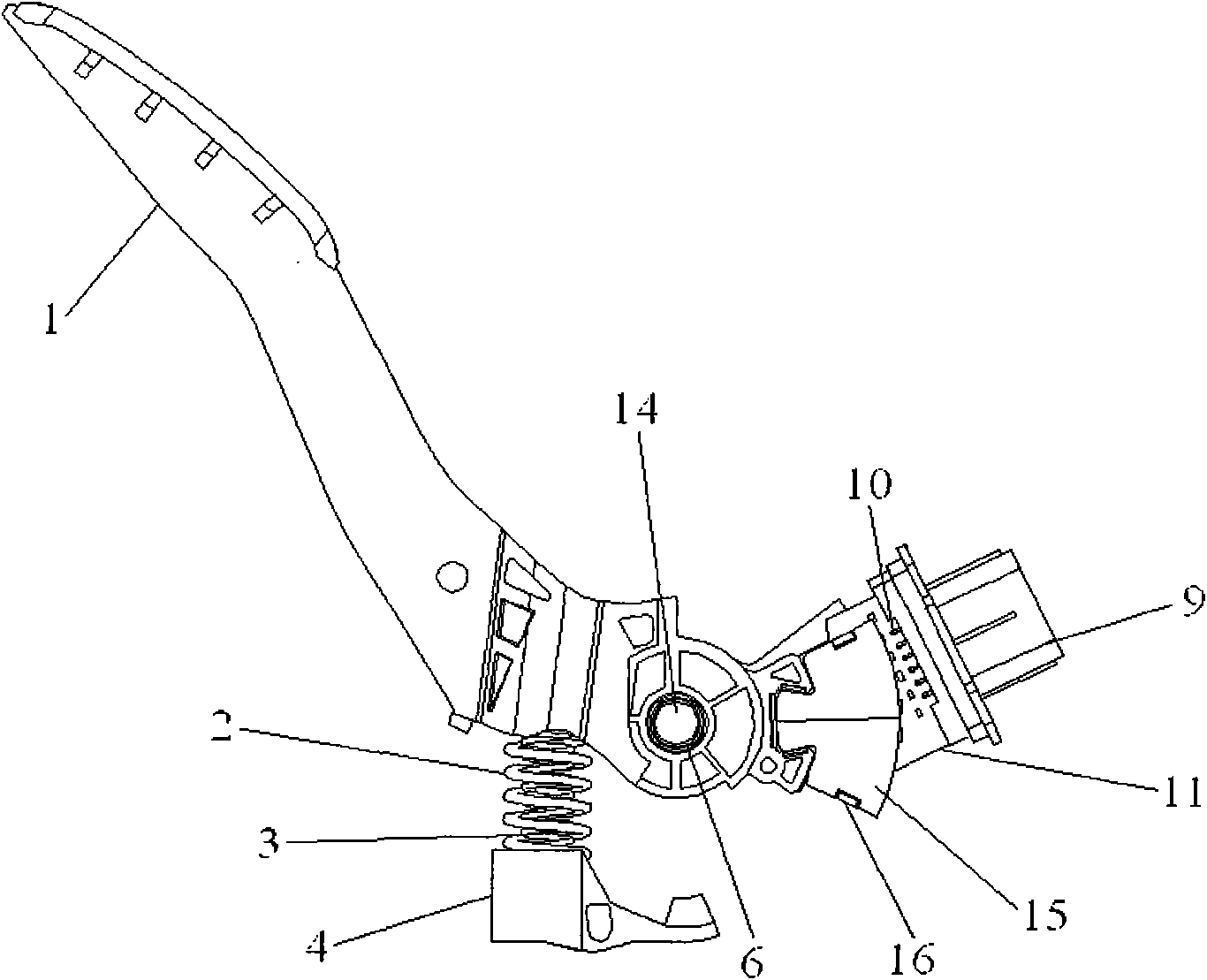

[0025] A kind of non-contact automobile electronic accelerator pedal, its structure is as follows Figure 1-5 As shown, the non-contact automotive electronic accelerator pedal includes a pedal arm 1, an outer spring 2, an inner spring 3, a spring base 4, a bottom plate 5, a shaft sleeve 6, a side cover plate 7, a base 8, a connector 9, and a terminal block 10. Chip 11 , kickdown device 12 , fixed piece 13 , shaft 14 , magnet separator 15 , and magnet 16 . The shaft 14 is arranged at the center of the lower end of the pedal arm 1 , and the shaft sleeve 6 is arranged outside the shaft 1 . One end of the outer spring 2 and the inner spring 3 is connected with the bottom of the pedal arm 1, and the other end is arranged in the spring base 4. part, with the pedal arm 1 through ultrasonic welding or high-temperature welding, the magnet 16 is riveted inside the magnet partition 15, the shapes of the magnet partition 15 and the magnet 16 are fan-shaped, the chip 11 is ultrasonically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com