Novel catalyst for aldol condensation reactions

A technology of aldol condensation and products, applied in the field of aldol condensation reaction, can solve problems such as negative environmental impact, complex, expensive process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] General conditions: 4 ml saline solution (see Table 3) was stirred continuously and protected from light.

[0036] Reactant concentration: acetaldehyde: 0.1-0.5M; acetone: 0.5-1M.

[0037] Temperature = 25°C (room temperature) or 35°C.

[0038] The degree of conversion of the reaction was determined by UV-visible absorption measurements of the consumption of the reactant acetone, and the formation of the product acetaldehyde: acetone was monitored at 269 nm, the acetaldehyde product (2,4,6-octatrienal) at 320 and 350 nm monitoring.

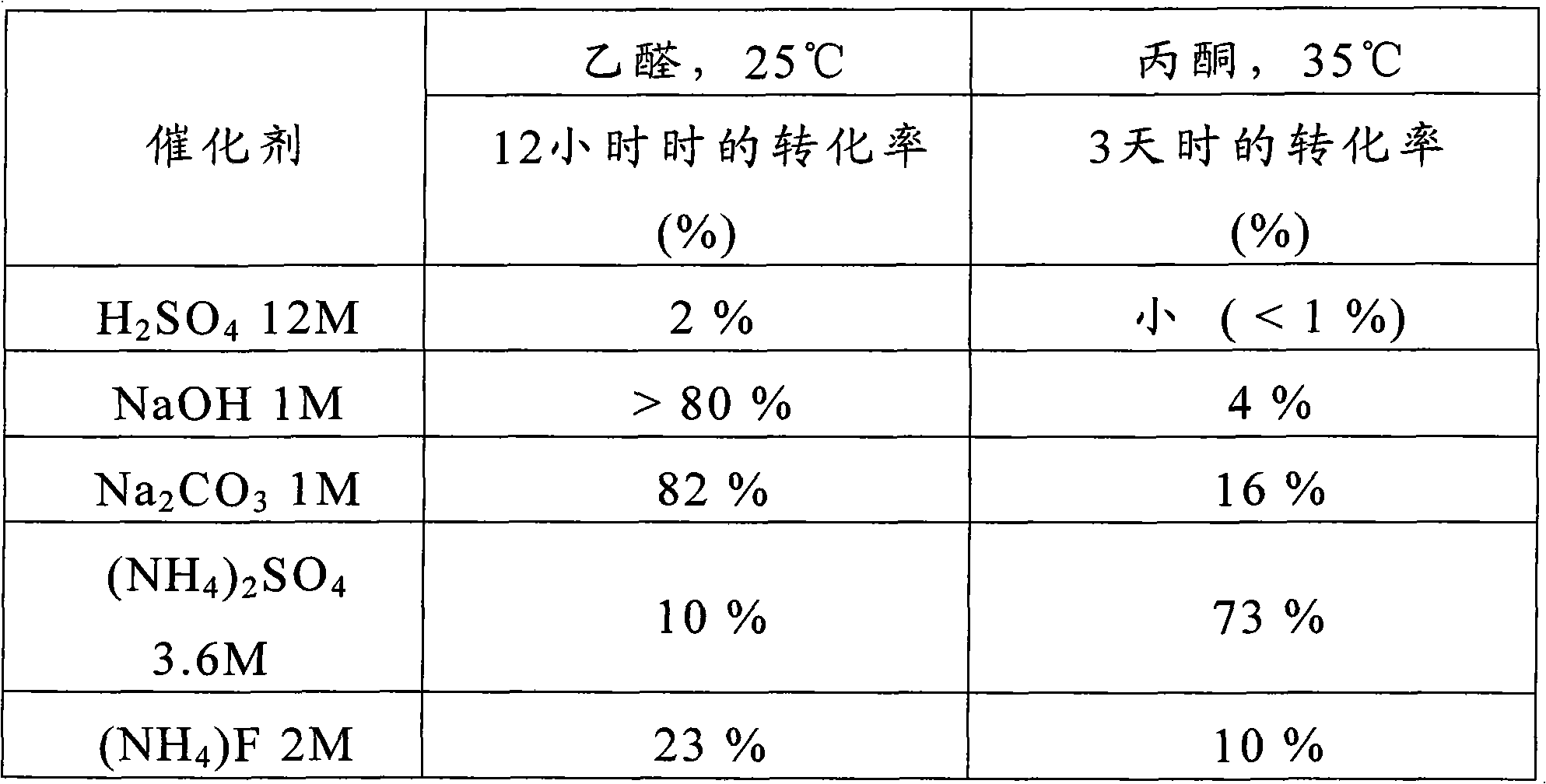

[0039] Table 1 : Comparison between commonly used catalysts and the catalysts mentioned in the present invention for different aldehydes and ketones (all solutions in water)

[0040]

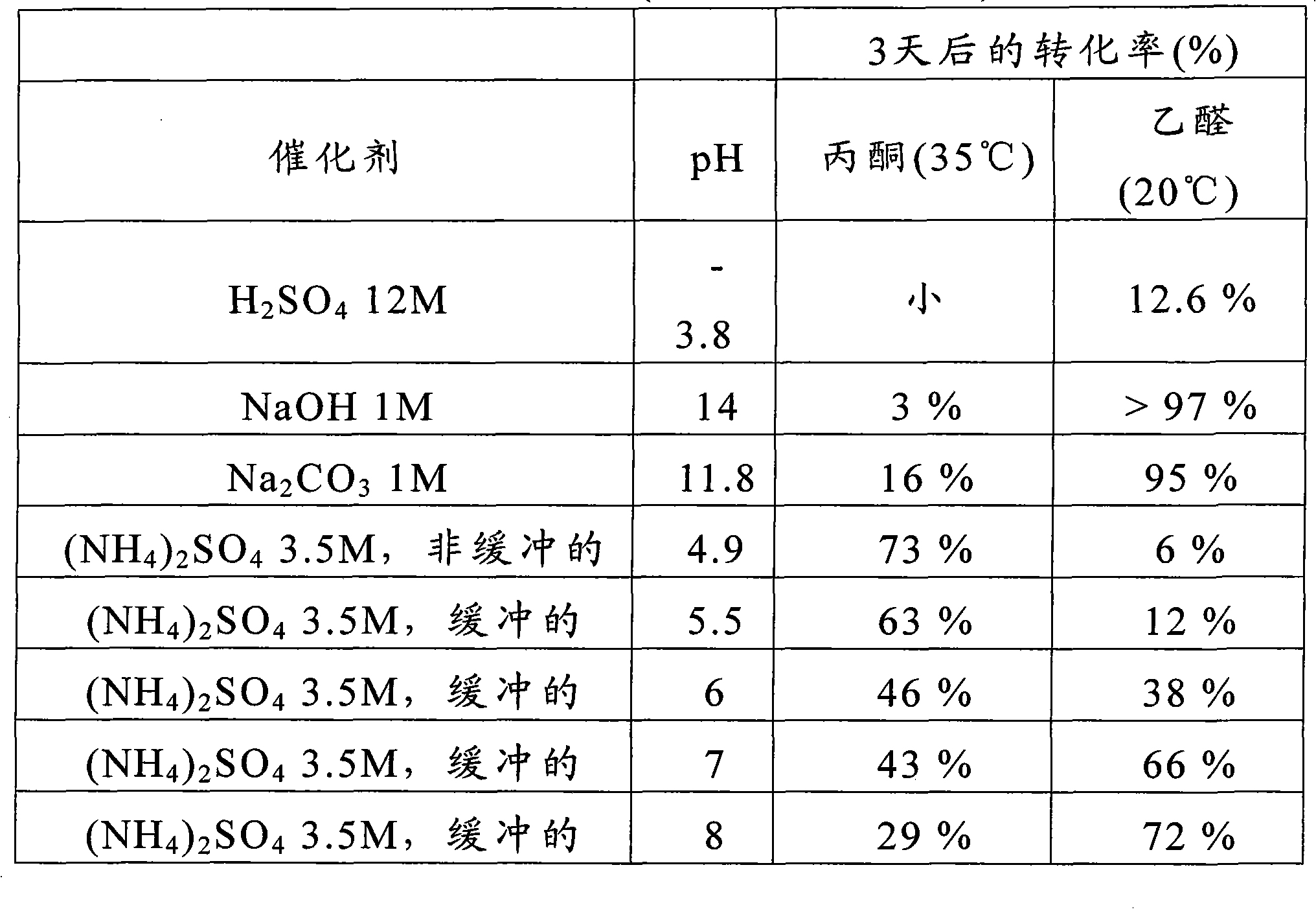

[0041] Table 2: For the reaction of acetaldehyde, the comparison of the catalytic efficiency of various inorganic ammonium salt catalysts mentioned in the present invention (all solutions are in water)

[0042] Catalyst / Temperature

Conversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com