Method and system for purifying flue gas generated by incinerating waste materials

A purification system and waste technology, applied in the field of flue gas purification, can solve the problems of increasing metal emission concentration, long impact time, easy condensation, etc., and achieve the effect of ensuring full decomposition, eliminating dioxins, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

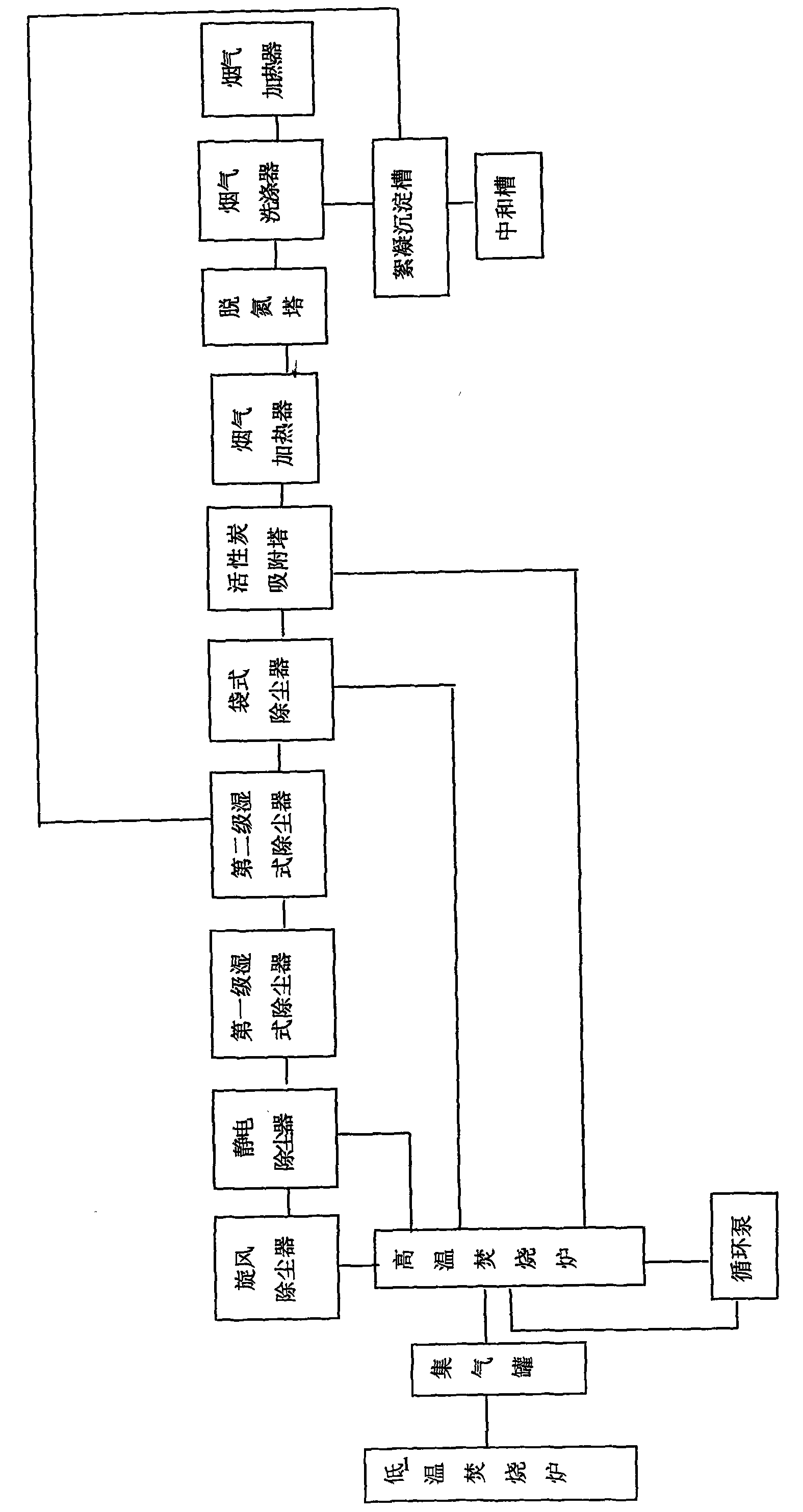

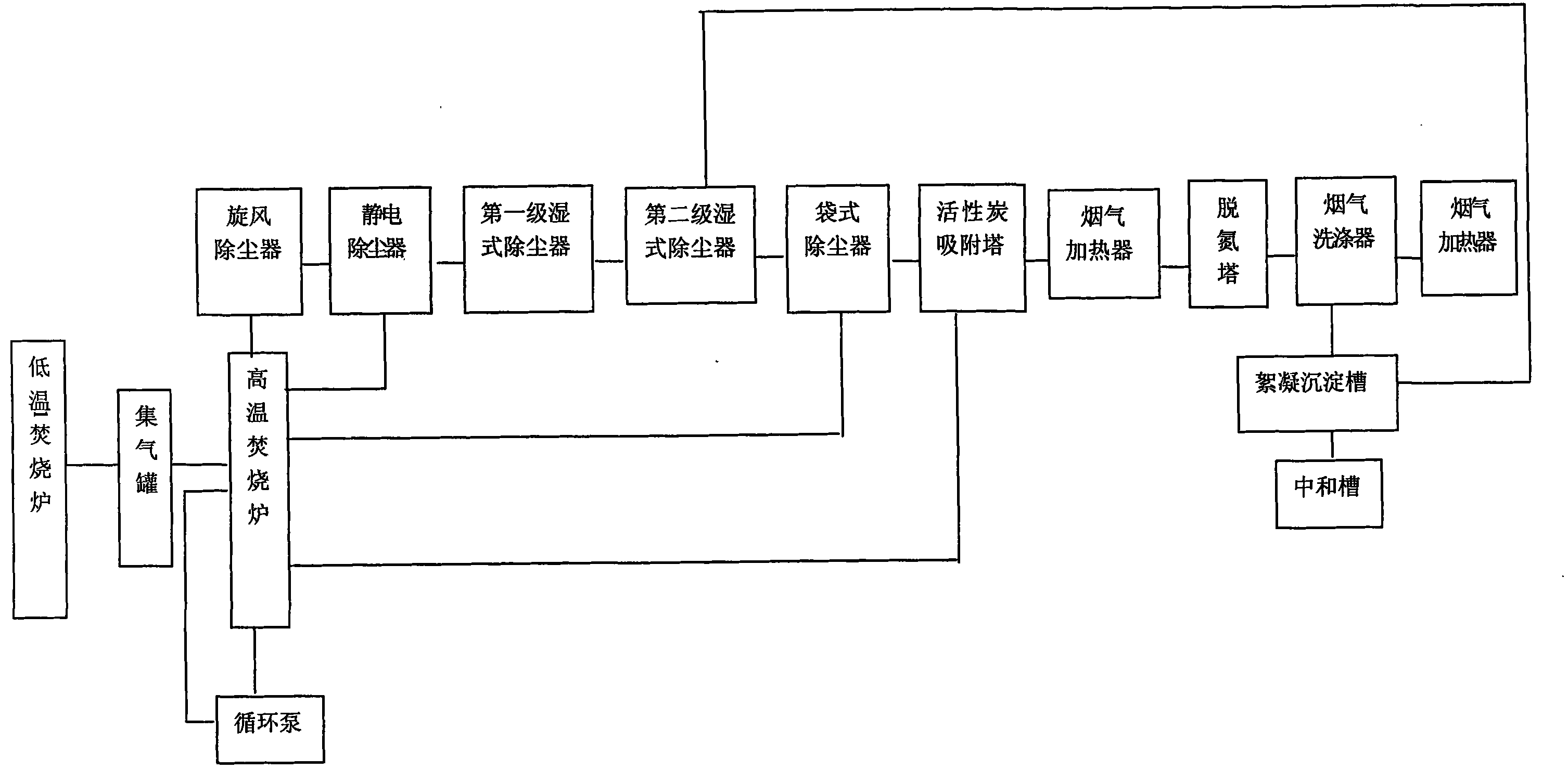

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The purification method of the flue gas produced by waste incineration of the present invention comprises the following steps:

[0031] (1) High-temperature incineration: Send the waste to a high-temperature incinerator at 1000-1200°C for 1.7-3s.

[0032] (2) Dust removal and cooling treatment: After the flue gas generated by the high-temperature incinerator passes through the cyclone dust collector and the electrostatic precipitator in sequence, the temperature of the flue gas drops to 500 ° C, and then it is treated by two-stage wet dust collectors. Inject limestone solution to remove acid gas, spray NaCO solution into the second-stage wet dust collector to destroy dioxins in the flue gas, and reduce the temperature of the flue gas to below 200°C within 2-4s, so that dioxins cannot be generated. The flue gas after cooling is treated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com