Electrothermal cutting machine with automatic voltage-stabilized and constant-current device

A technology of automatic voltage stabilization and cutting machine, which is applied in the direction of output power conversion device, electrical components, AC power input conversion to DC power output, etc., to achieve the effect of good consistency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

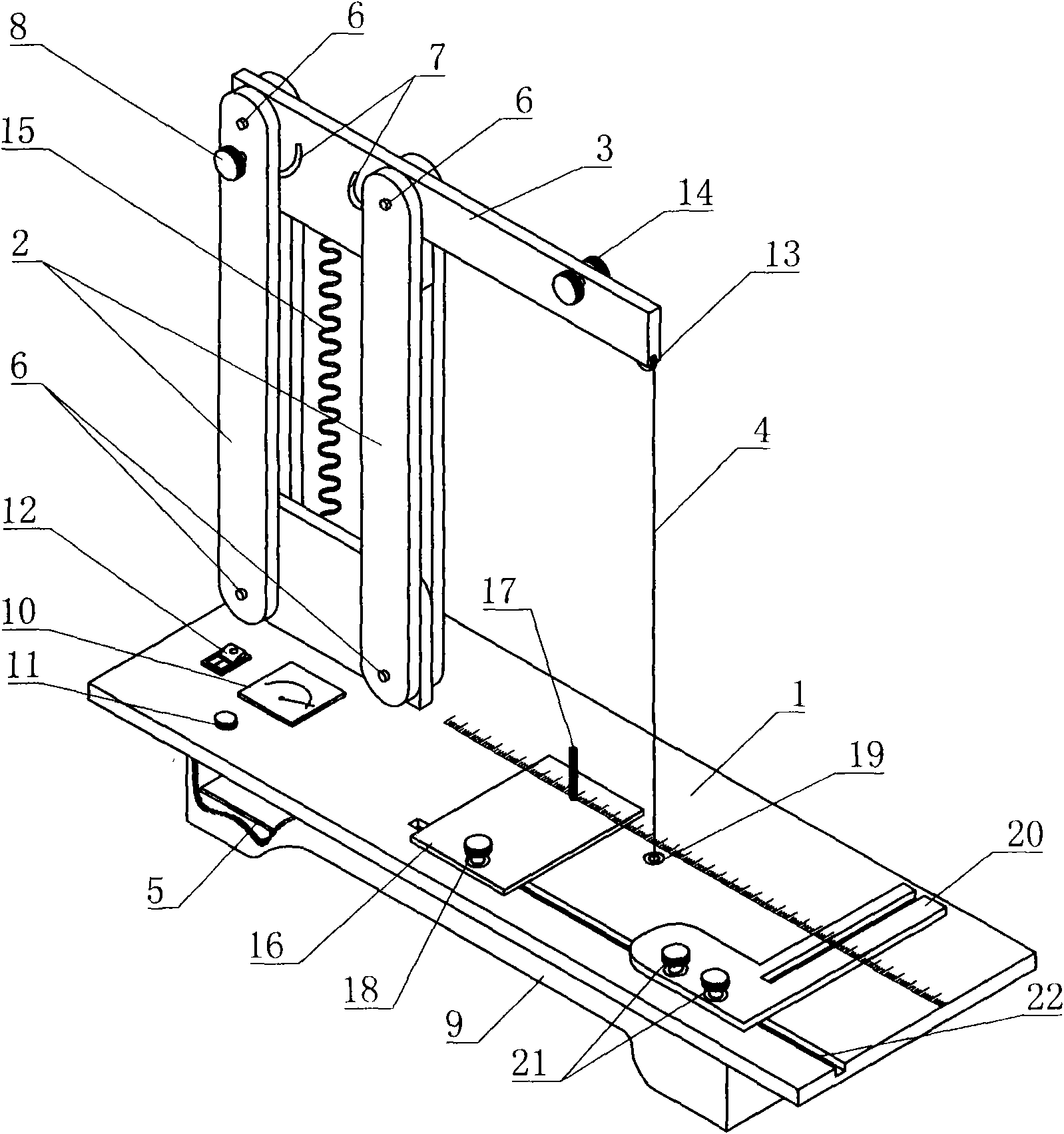

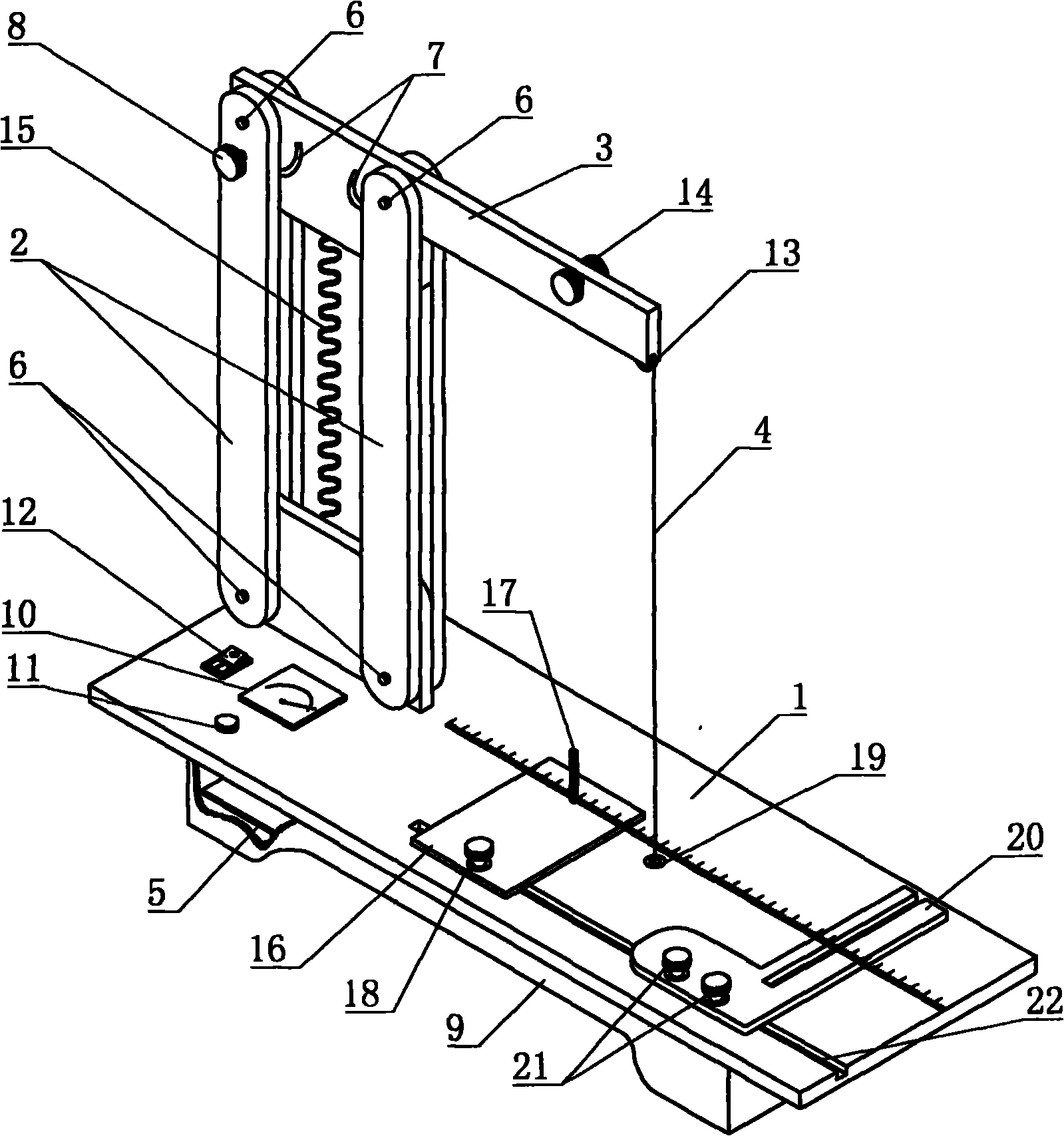

[0023] Embodiment one: figure 1 It is a structural schematic diagram of an electric thermal cutting machine equipped with an automatic voltage stabilizing constant current device in the present invention. The present invention is equipped with the electrothermal cutting machine of automatic voltage stabilizing and constant current device, is made up of work table board 1, vertical arm 2, heating wire support arm 3, heating wire 4 and the circuit board 5 of power supply heating wire working current, is characterized in that The vertical arm 2 described above is composed of two movable vertical arms parallel to each other, and a movable vertical arm shaft 6 is respectively arranged at the upper and lower ends of each movable vertical arm, and the two movable vertical arm shafts 6 at the upper end are connected with the described vertical arm shafts. The left side of the heating wire support arm 3 is movably connected, and the two movable vertical arm shafts 6 at the lower end ar...

Embodiment 2

[0025]Embodiment 2: The right end of the heating wire support arm 3 of the present invention is provided with a heating wire tension spring 13, and the heating wire 4 is tightly pressed on the heating wire tension spring 13, and then the heating wire arranged in the heating wire support arm 3 is wound on the disk 14, and be electrically connected with the helical wire 15 located in the middle of the two movable vertical arms 2, and then be connected to the positive output terminal of the power supply of the said circuit board 5. A power switch 12, a center-of-circle distance adjusting plate 16, a heating wire through hole 19, a moving square 20 and a chute 22 are arranged successively from left to right on the workbench 1. Said center-of-circle distance adjustment plate 16 is provided with a center-of-circle positioning rod 17 and a center-of-circle fixing button 18; two square-square fixing buttons 21 are also installed side by side on the described moving square 20, and the c...

Embodiment 3

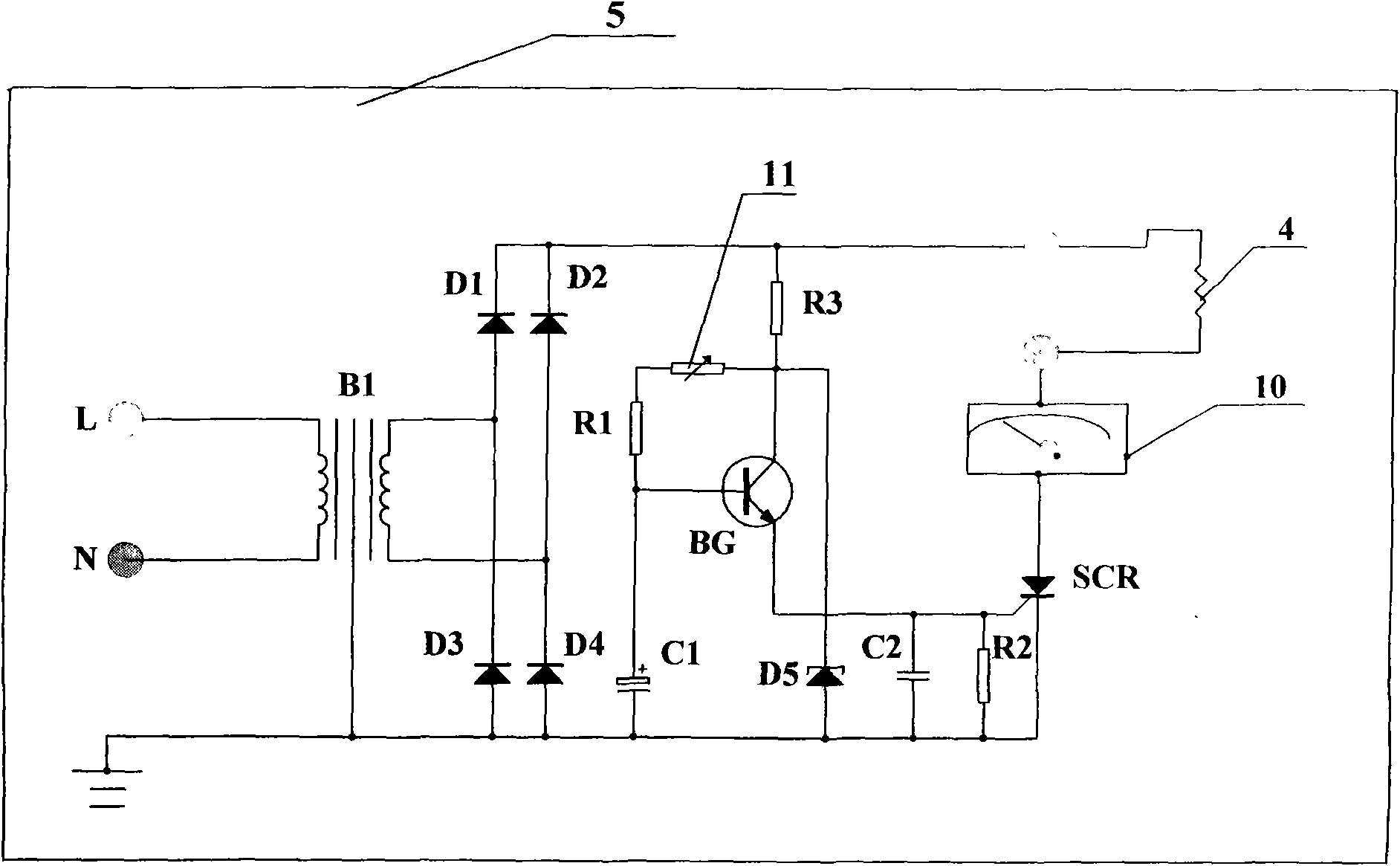

[0027] Embodiment three: the potentiometer 11 in the circuit board 5 of the present invention is also connected in series with a resistor R 1 , when the resistance value of the potentiometer is manually adjusted to the minimum value, it is affected by the series resistor R 1 The trigger current of the control pole of the thyristor SCR is also limited within the set range. The operating current of the heating wire 4 is also regulated within the set range. The base of the triode BG is connected in parallel with the negative output terminal of the power supply C 1 , with potentiometer 11 and series resistor R 1 Form a pulse phase shifting circuit. Power step-down transformer B 1 It is made of iron core inductor winding, with stable performance and low price. Parallel capacitor C between the control pole and the cathode of the thyristor SCR 2 and resistor R 2 , Improve the pulse waveform and improve the anti-jamming performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com