Method for preparing super hydrophobic timber

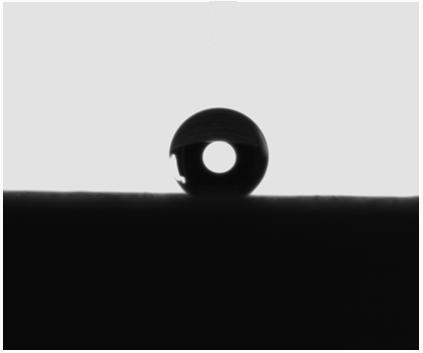

A super-hydrophobic, wood technology, applied in the direction of wood impregnation, wood impregnation, wood processing appliances, etc., can solve the problems of high energy consumption, high cost, complex process, etc., and achieve low energy consumption, low production cost, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0007] Embodiment 1: A method for preparing superhydrophobic wood in this embodiment is carried out according to the following steps: 1. Prepare potassium methyl silicate aqueous solution according to the concentration of potassium methyl silicate at 0.1% to 20% (mass); 2. Submerge the wood in the potassium methyl silicate aqueous solution prepared in step 1 for 5h to 30h; 3. Under the condition that the temperature of the potassium methyl silicate aqueous solution is kept at 10°C to 80°C, adjust the methyl silicate The pH value of the aqueous potassium solution is 9 to 13.5; 4. Pass carbon dioxide gas into the potassium methyl silicate aqueous solution, and stop feeding carbon dioxide gas when the pH value of the potassium methyl silicate aqueous solution is 7 to 8.8; 5. Stand still After 0.1h to 30h, put the wood in a vacuum drying oven, and dry it for 10min to 10h at a vacuum degree of 0.070MPa to 0.095MPa and a temperature of 40°C to 140°C to obtain superhydrophobic wood. ...

specific Embodiment approach 2

[0009] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the concentration of potassium methyl silicate in step 1 is 1%-18% (mass). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of potassium methyl silicate in step 1 is 10% (by mass). Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com