Loader and circular cooling and lubricating system of torque converter thereof

A technology of circulating cooling and lubricating system, applied in lubricating system, transportation and packaging, earth mover/shovel, etc., can solve the problems of reduced working reliability, reduced reliability, difficulty in achieving cooling and lubrication, etc. Effect of cooling lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The core of the present invention is to provide a circulating cooling and lubricating system for the torque converter to perform all-round cooling and lubricating for the internal parts of the torque converter, so that the torque converter can work for a long time under high temperature conditions.

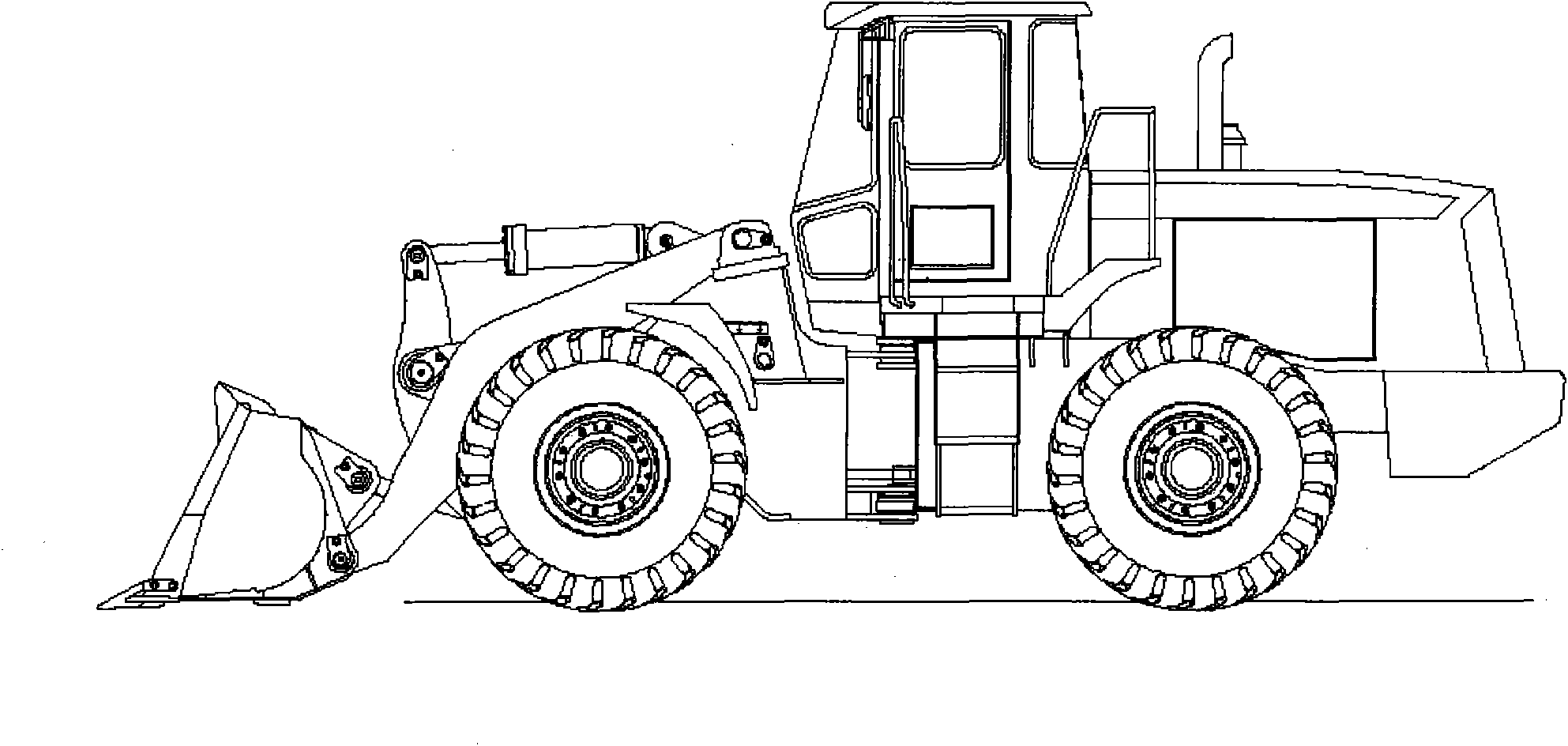

[0044] Without loss of generality, this embodiment will be specifically described below with the loader as the main body.

[0045] See image 3 , which is a schematic diagram of the overall structure of the loader according to this embodiment.

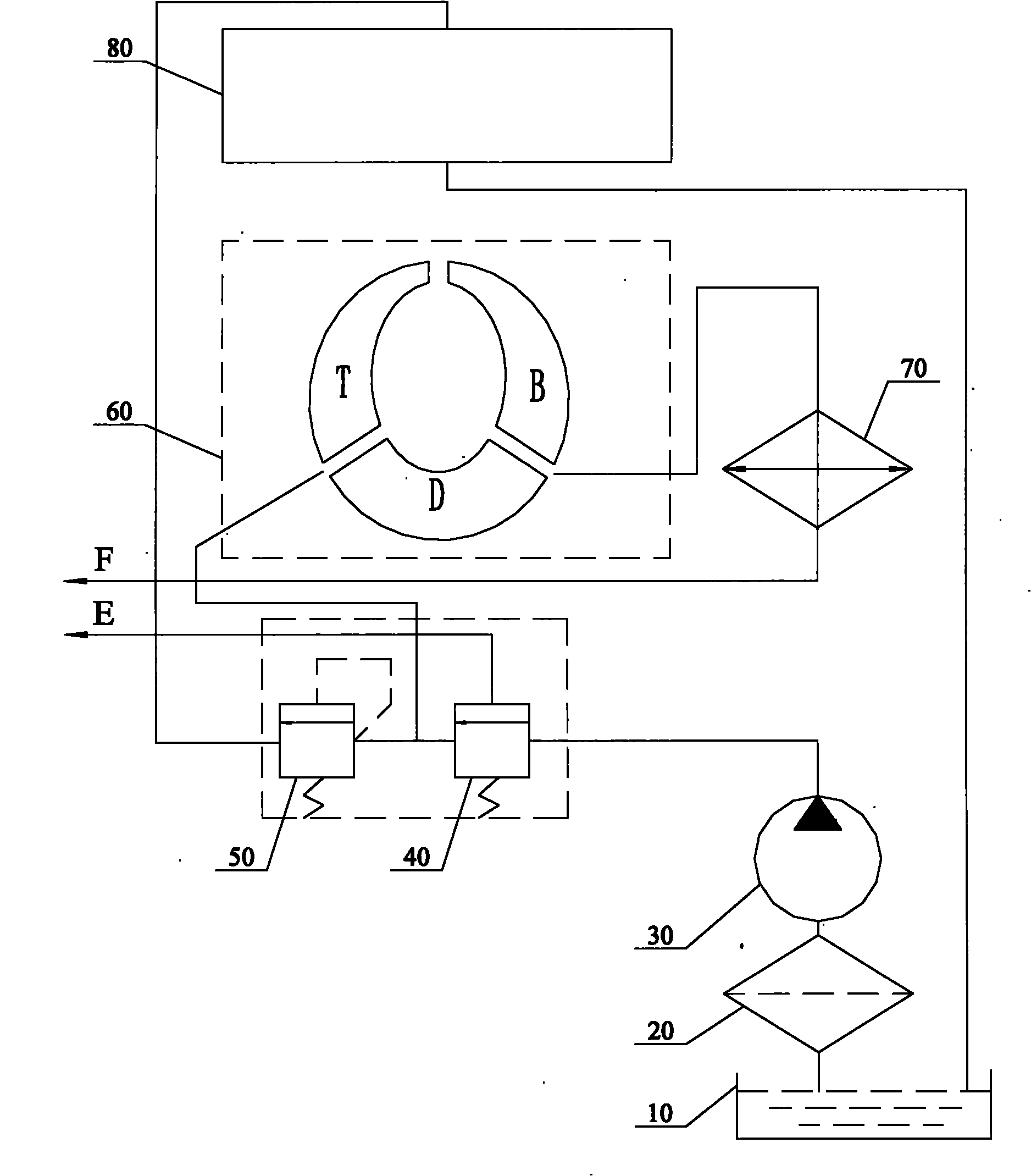

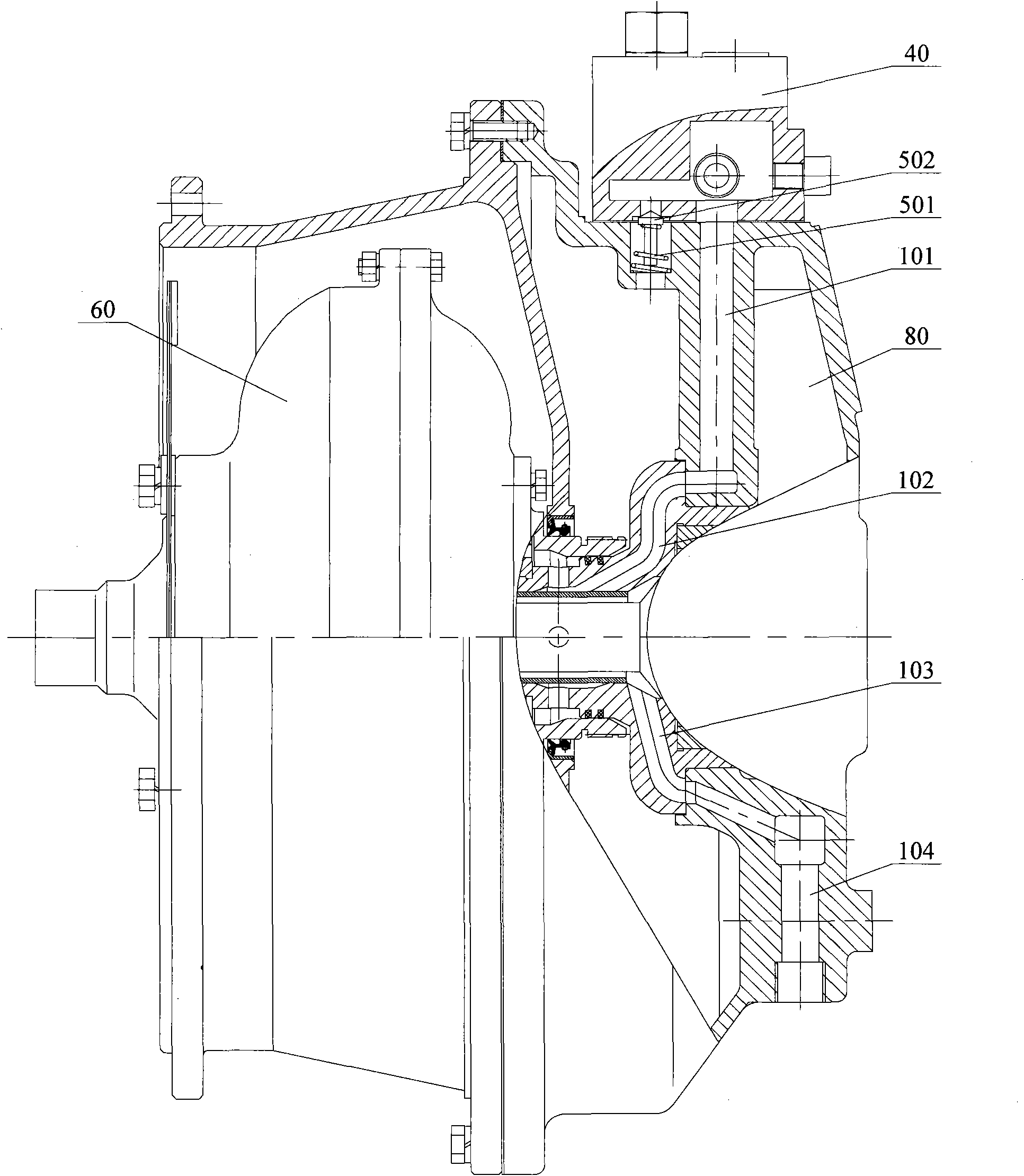

[0046] The main functional components of the loader, such as the working device, power transmission system, control system, hydraulic system and electrical system, are basically the same as those of the prior art, and those skilled in the art can fully realize them based on the prior art, so this article will not repeat them here. See Figure 4 , which is a schematic diagram of the torque converter circulating cooling and lubricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com