On-line monitoring system for coal-combustion overall process of power station boiler

A technology for power plant boilers and monitoring systems, applied in control systems, combustion control, measurement devices, etc., can solve the problems of inability to adapt to the changeable coal quality, unable to adapt to frequent changes in coal quality, etc. Real-time response and accurate measurement of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

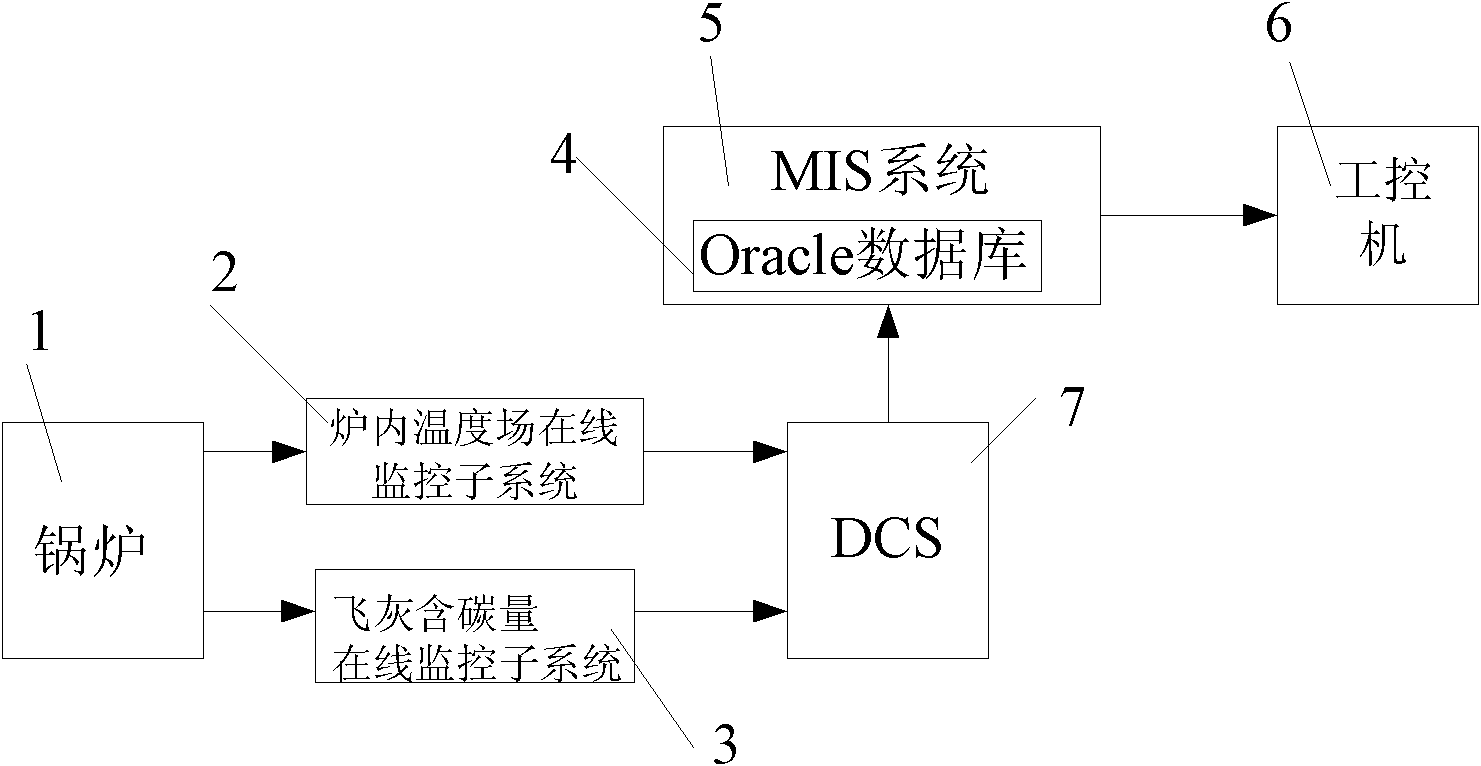

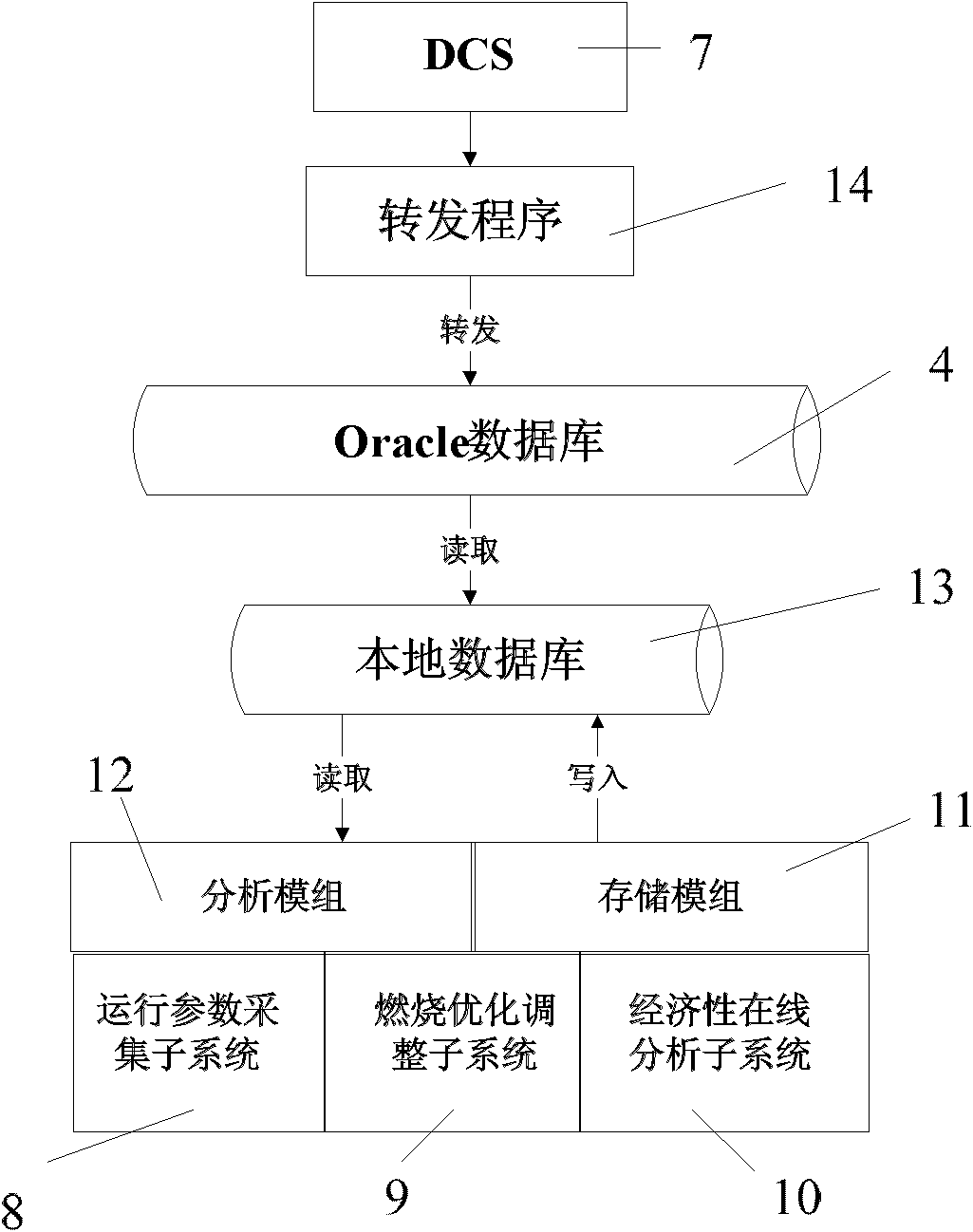

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail: see figure 1 , the present invention is implemented on the basis of the existing power plant boiler control system, so the online monitoring system for the whole process of coal combustion of the power plant boiler includes the DCS system 7 used in the existing power plant boiler control system and the system for downloading operation data from the DCS system 7 MIS system5. Among them, the DCS system 7 is respectively connected with the furnace temperature field monitoring subsystem 2 and the fly ash carbon content monitoring subsystem 3 , and the MIS system 5 is also connected with the industrial computer 6 .

[0019] The temperature field monitoring subsystem 2 in the furnace includes a number of infrared thermometers, each infrared thermometer is fixedly arranged outside the fire viewing hole of the boiler furnace, and 3-5 layers of temperature measuring points are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com