Hydraulic static blasting expansion tube

A technology of static blasting and expansion tubes, applied in blasting and other directions, can solve the problems of large amount of expansion agent, pollution of the environment by waste residue, high production cost, etc., and achieve the effects of low production cost, mature technology and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

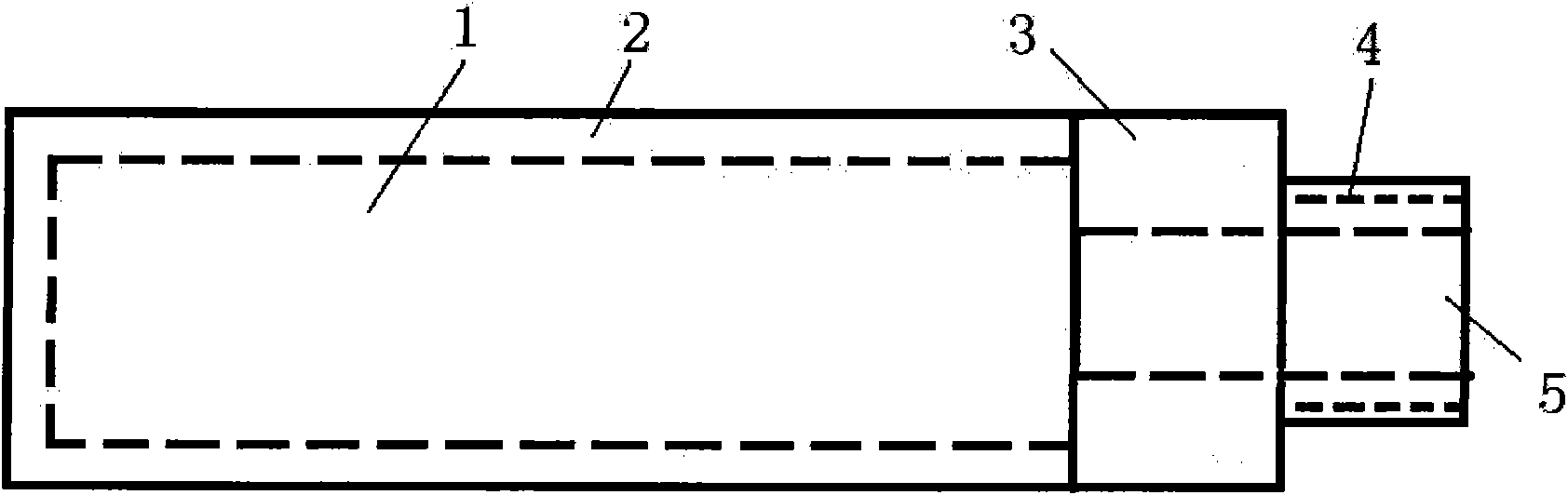

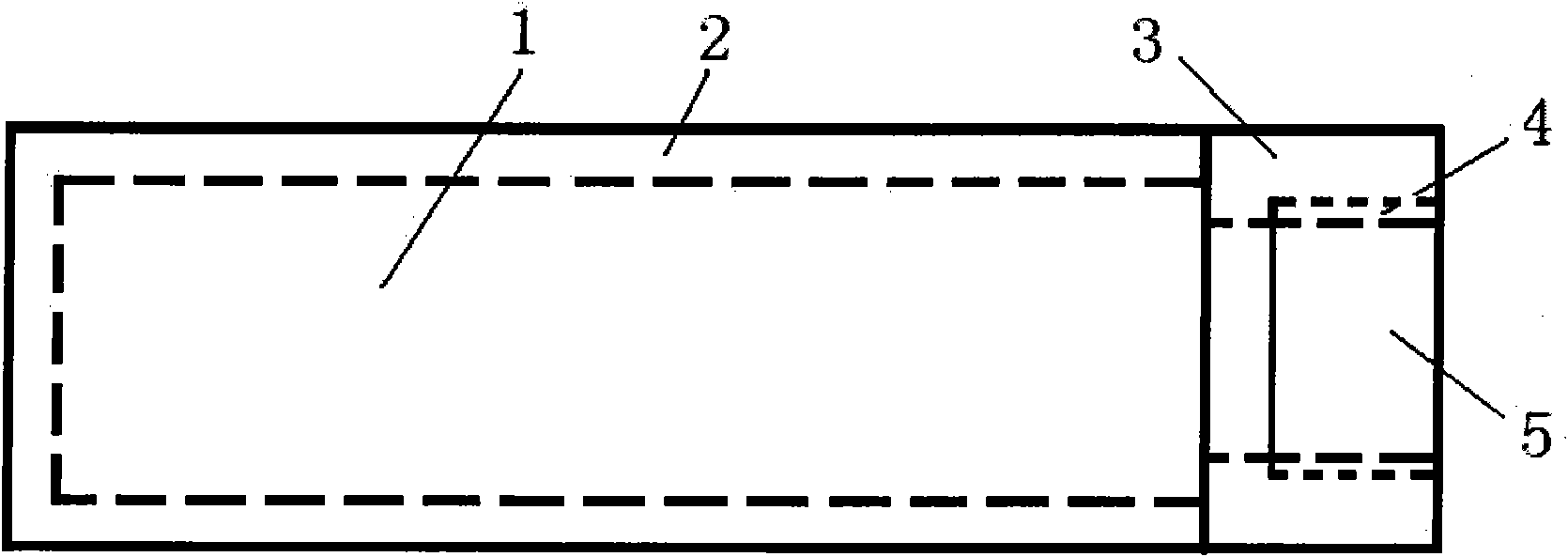

[0022] Such as figure 1 , figure 2 Shown: hydraulic static blasting expansion pipe (A) of the present invention, expansion pipe lumen (1), expansion hose body (2), expansion pipe joint (3) constitute, its pipe joint or pipe interface (4) can be designed as Inscribed or inscribed form structures. The connection and fixation of the expansion hose body (2) and the joint (3) can be completed by prior art; its external or internal structure is a threaded structure or other structures of the prior art. Its expansion hose body (2) adopts durable pressure-resistant elastic material (such as rubber etc.) to make, in order to avoid expansion tube elongation under hydraulic pressure, can be designed to add high-strength fiber method to solve longitudinally. When it is hydraulic, its elongation can be limited, and its direction can produce lateral expansion. Generally, it is required that the expansion volume should be 1-2 times or more to obtain the most ideal use effect.

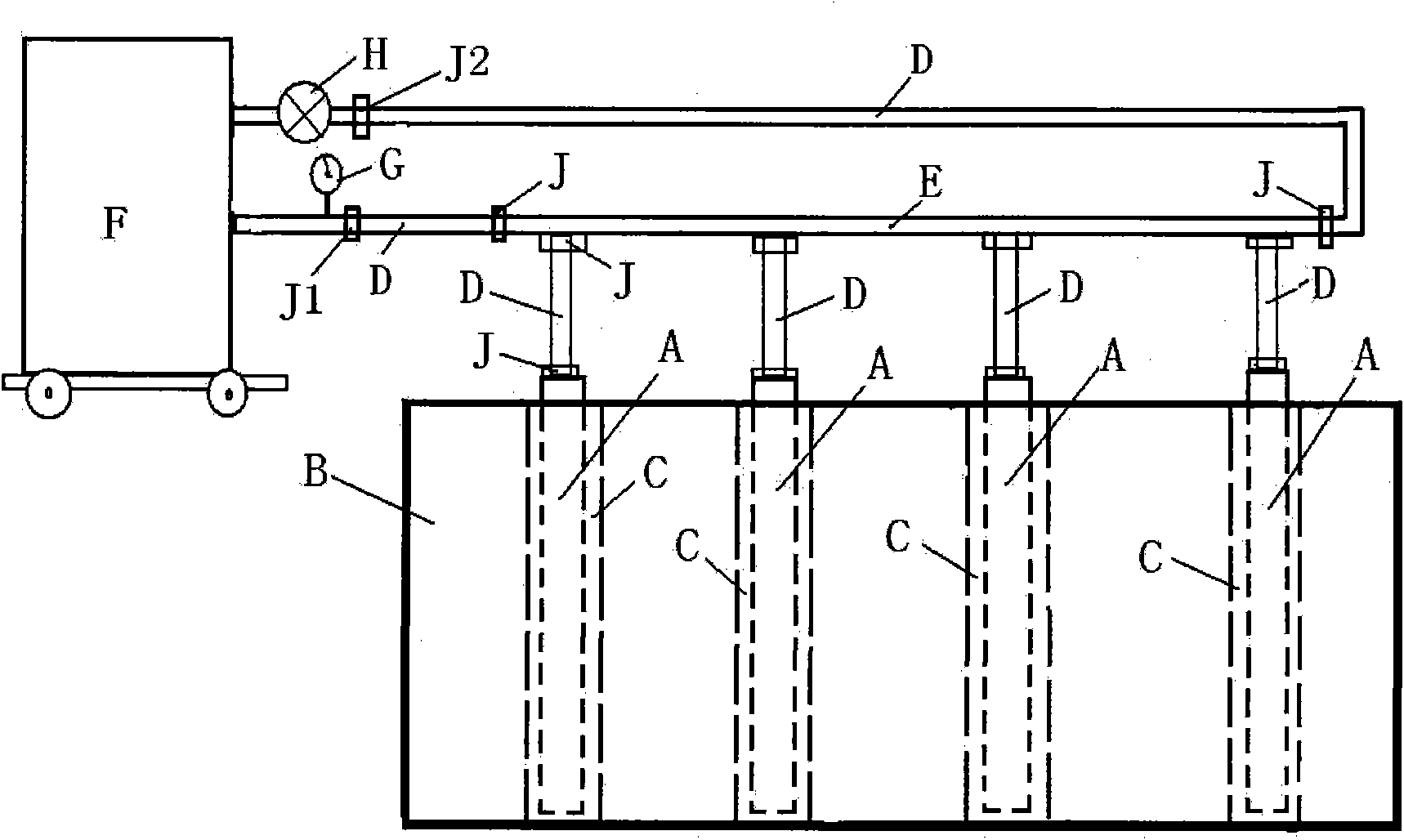

[0023] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com