Marine transformer poured with epoxy resin

A technology of epoxy resin and transformer, which is applied in the direction of transformer/inductor core, transformer/inductor coil/winding/connection, etc. It can solve the problems of reliable insulation performance and other problems, and achieve good insulation performance, reliable product quality, and smooth operation. no noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

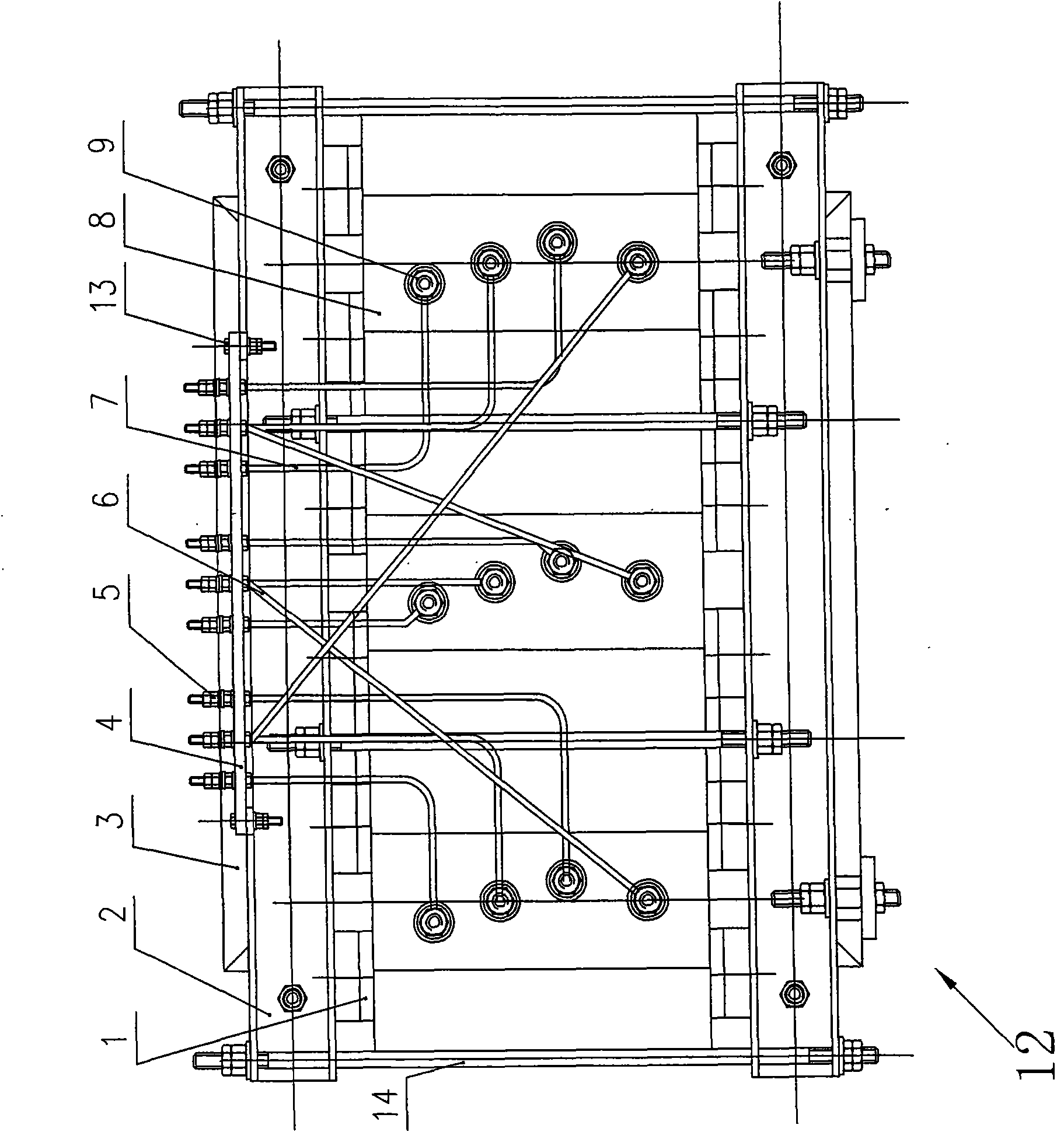

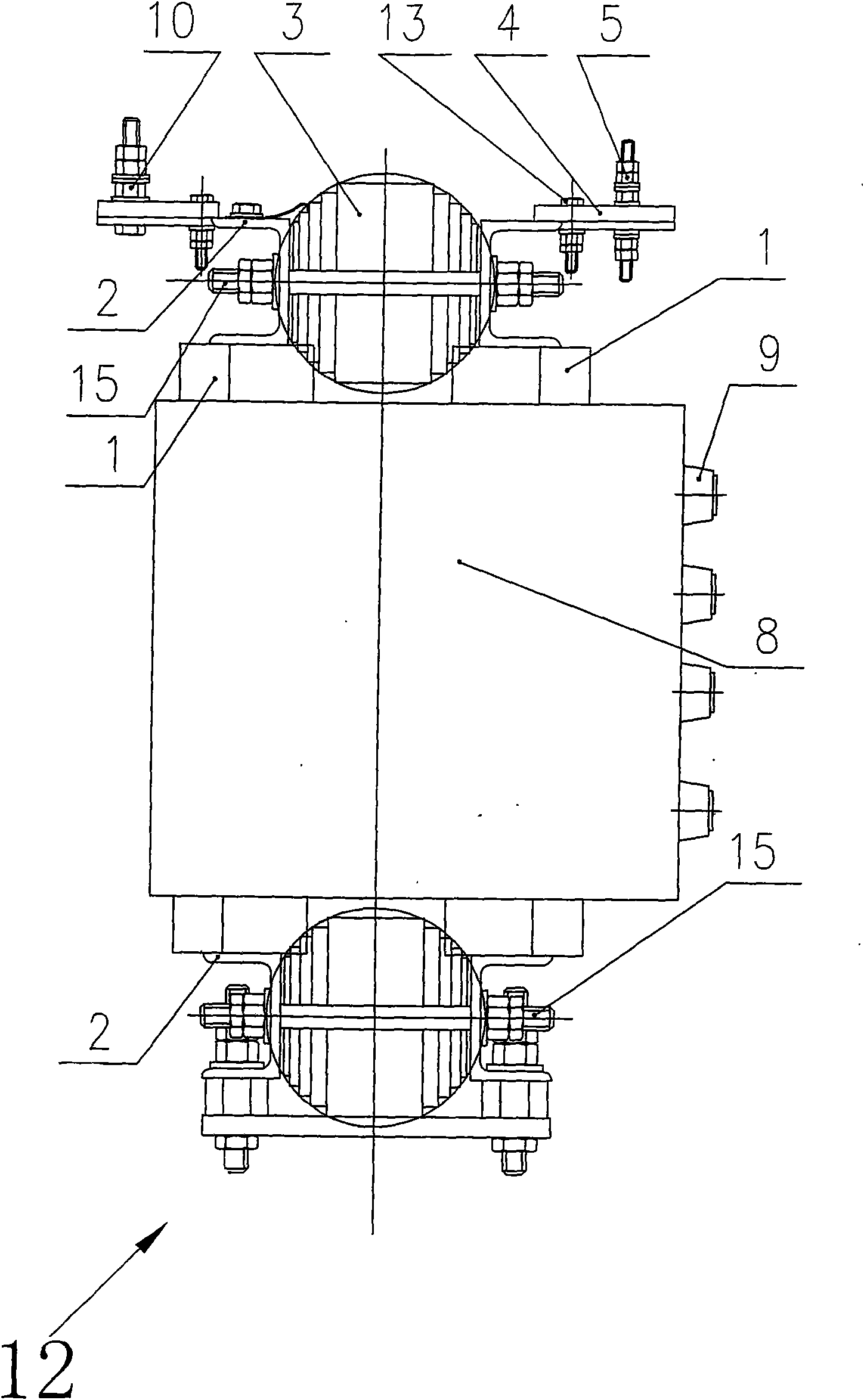

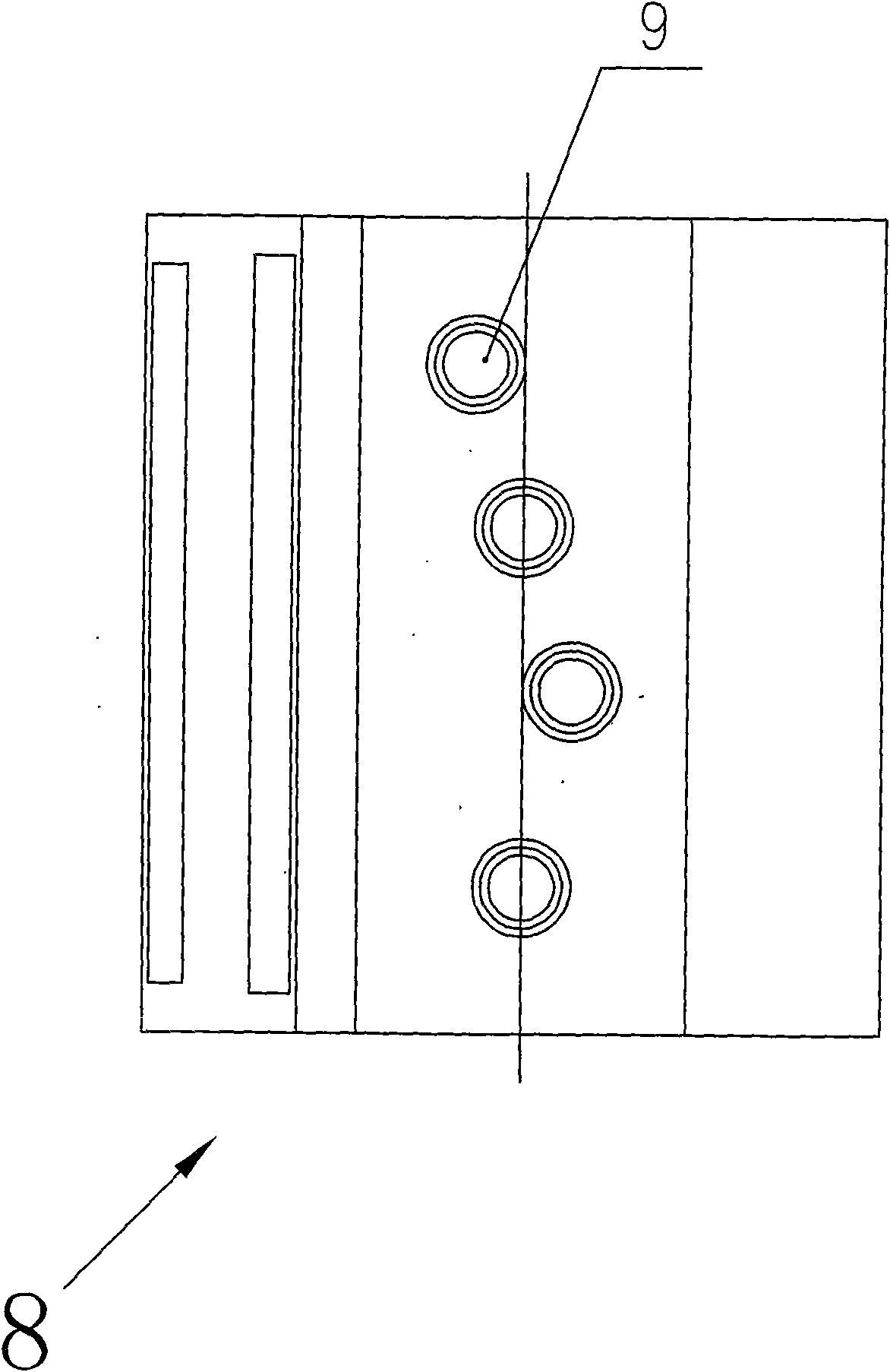

[0025] Referring to the accompanying drawings, the epoxy resin casting marine transformer 12 of the present invention is composed of a transformer pressing block 1, a clip 2, a transformer core 3, a wiring board 4, a primary terminal 5, an internal connecting cable 6, an outlet connecting wire 7, and a transformer coil 8. The coil outlet terminal 9, the secondary terminal 10 and the airway rod 11 are composed. A transformer pressure block 1 is fixed between the transformer coil 8 and the clamp 2. The terminal board 4 is installed and fixed on the clamp 2. The primary terminal 5 and the secondary terminal 10 are installed on the clamp 2 through the terminal board 4; the internal connecting cable 6 is connected between the transformer coils 8, and the outgoing connecting cable 7 is connected between the coil outgoing terminal 9 of the transformer coil 8 and the primary terminal 5 ; The primary coil 16 of the outer layer of the transformer coil 8 on the transformer iron core 3 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com