Method for producing a medical glass container

A glass container and container technology, applied in the field of medical glass containers and their production, can solve problems such as drug deterioration and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0048] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

[0049] [point burner 30]

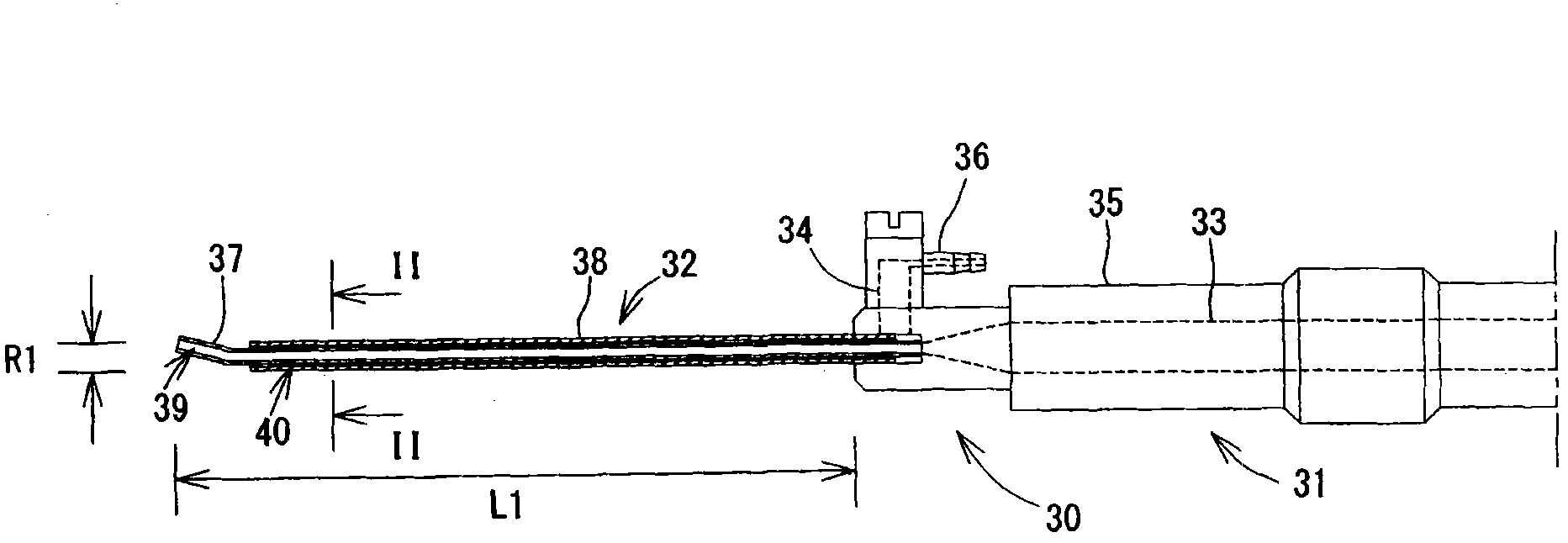

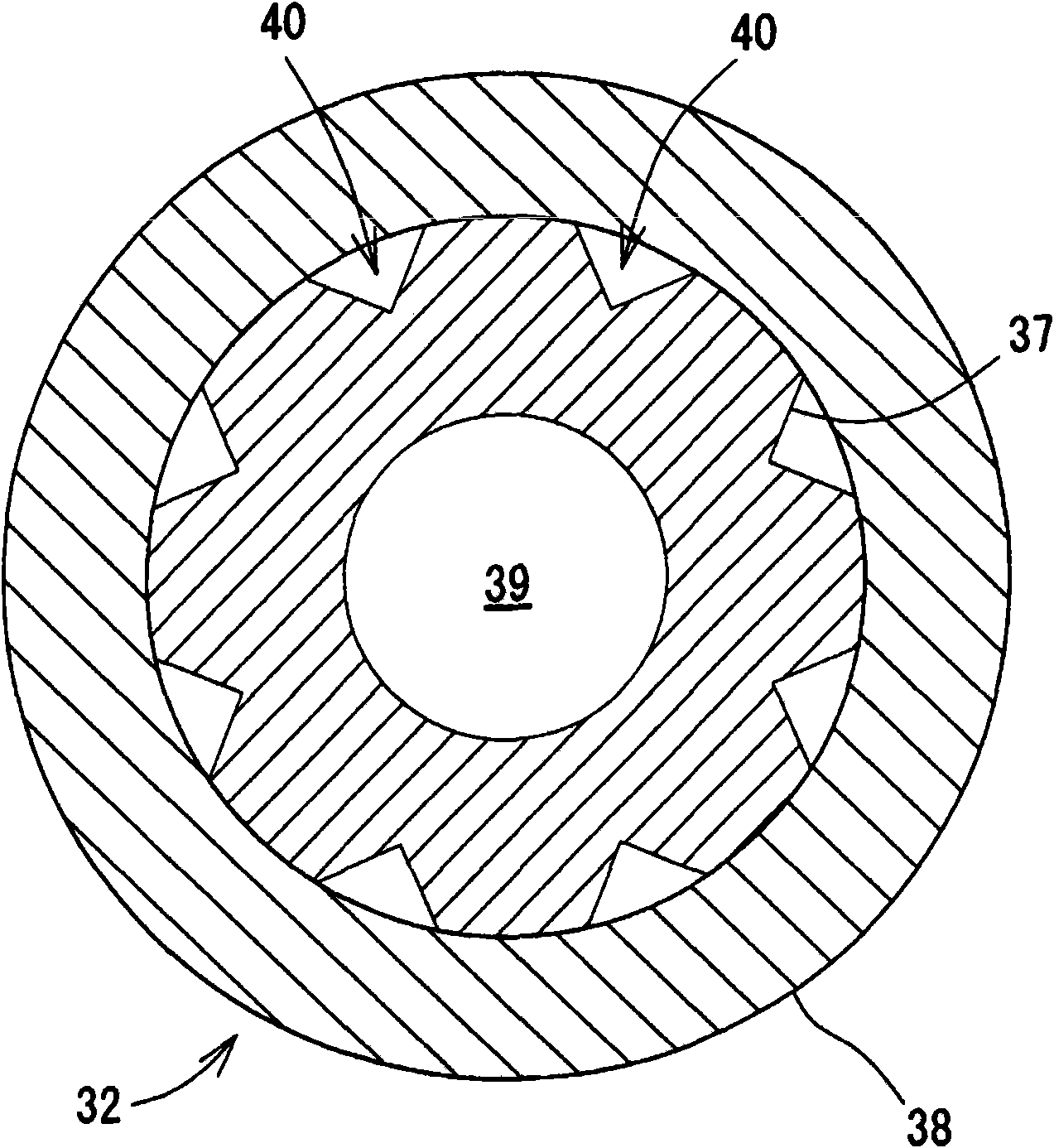

[0050] figure 1 and figure 2 The illustrated point burner 30 is used in the method of producing medical glass containers according to the invention. In the second process of the invention, the spot burner 30 is used to treat the inner surface of the ampoule 70 .

[0051] The point burner 30 is mainly roughly divided into a burner body 31 and a nozzle 32 . The burner body 31 has a first flow channel 33 through which mixed gas flows and a second flow channel 34 through which oxygen flows. Mixed gas is a mixture of gas and oxygen. The first flow passage 33 is formed by a first circular pipe 35 serving as a main part of the combustion body 31 . On the top end (nozzle 32 side) of the first circular pipe 35, the second flow passage 34 extending in the diameter direction is connected to the first flow passage 33, and the second flow passa...

no. 2 example

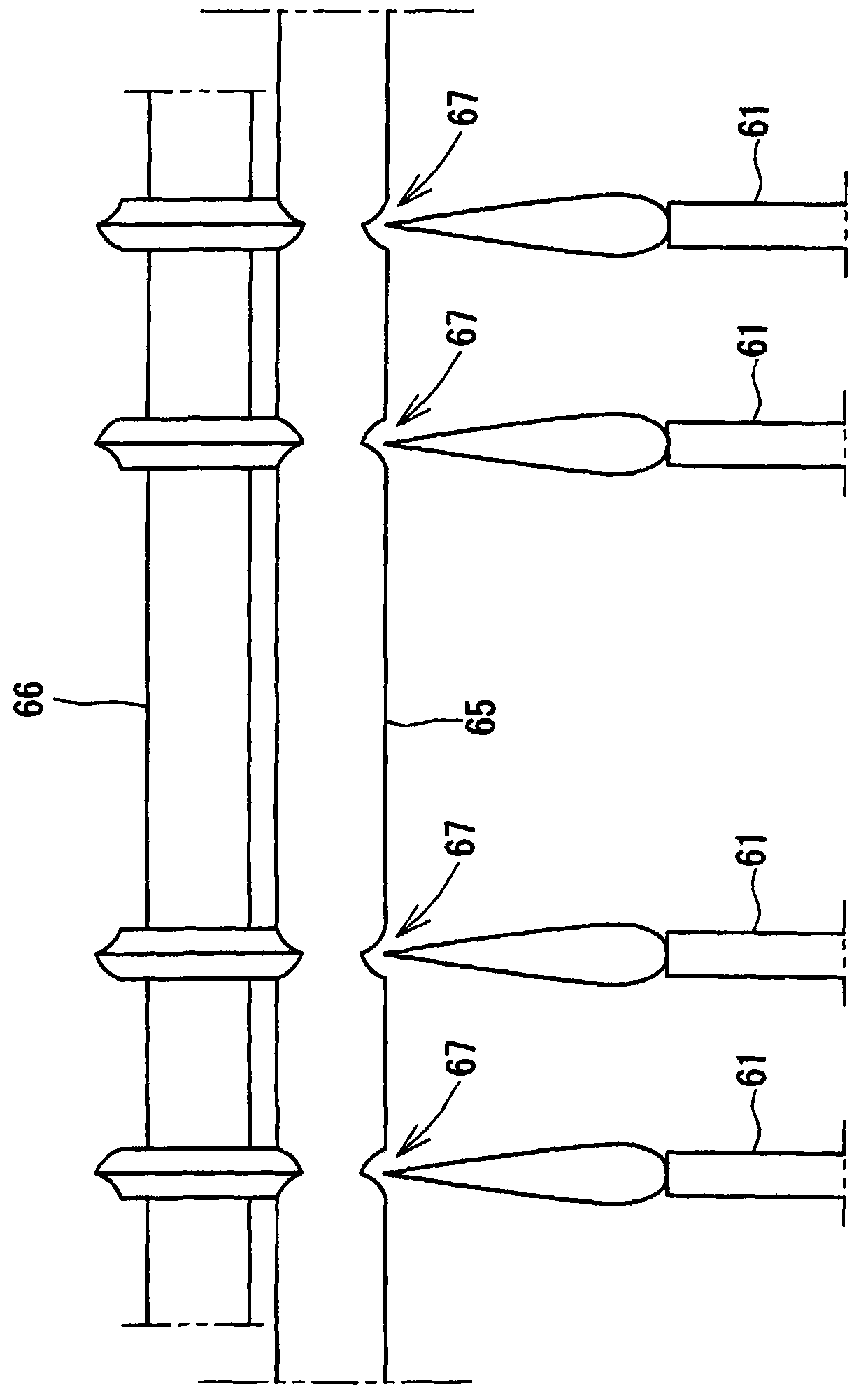

[0082] Hereinafter, a second embodiment of the present invention will be described. In the second embodiment, a vial 50 is used as the glass container of the present invention instead of the aforementioned ampoule 70 . In addition, the spot burner 10 suitable for the second process on the vial 50 is used instead of the spot burner 30 described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com