Automotive wire bundle punching die

An automotive wiring harness and die technology, applied in the field of die and die, can solve the problems of low degree of processing automation, high production cost, unsuitable for processing site requirements, etc., so as to reduce processing and manufacturing workload, simplify manufacturing, and reduce design and manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

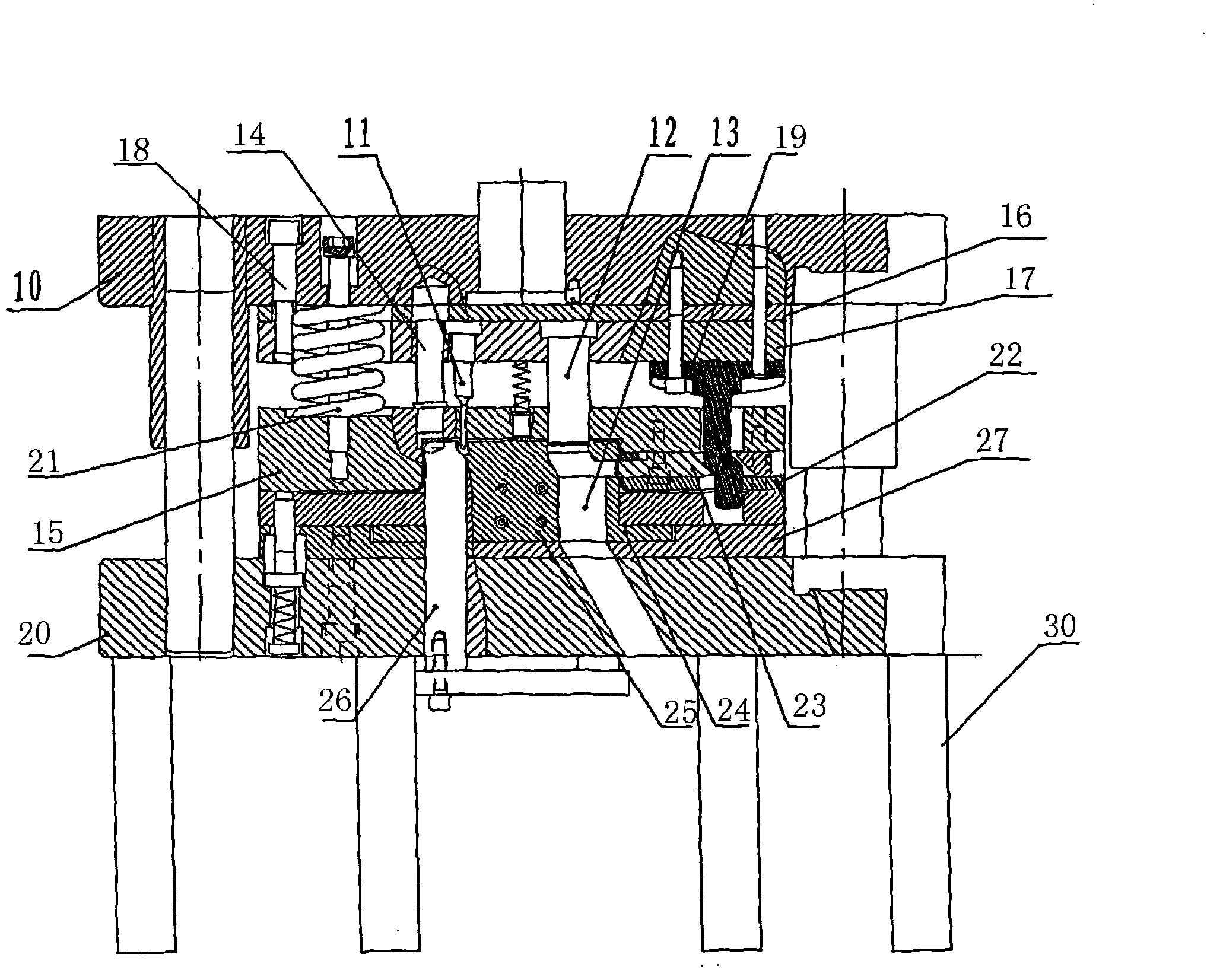

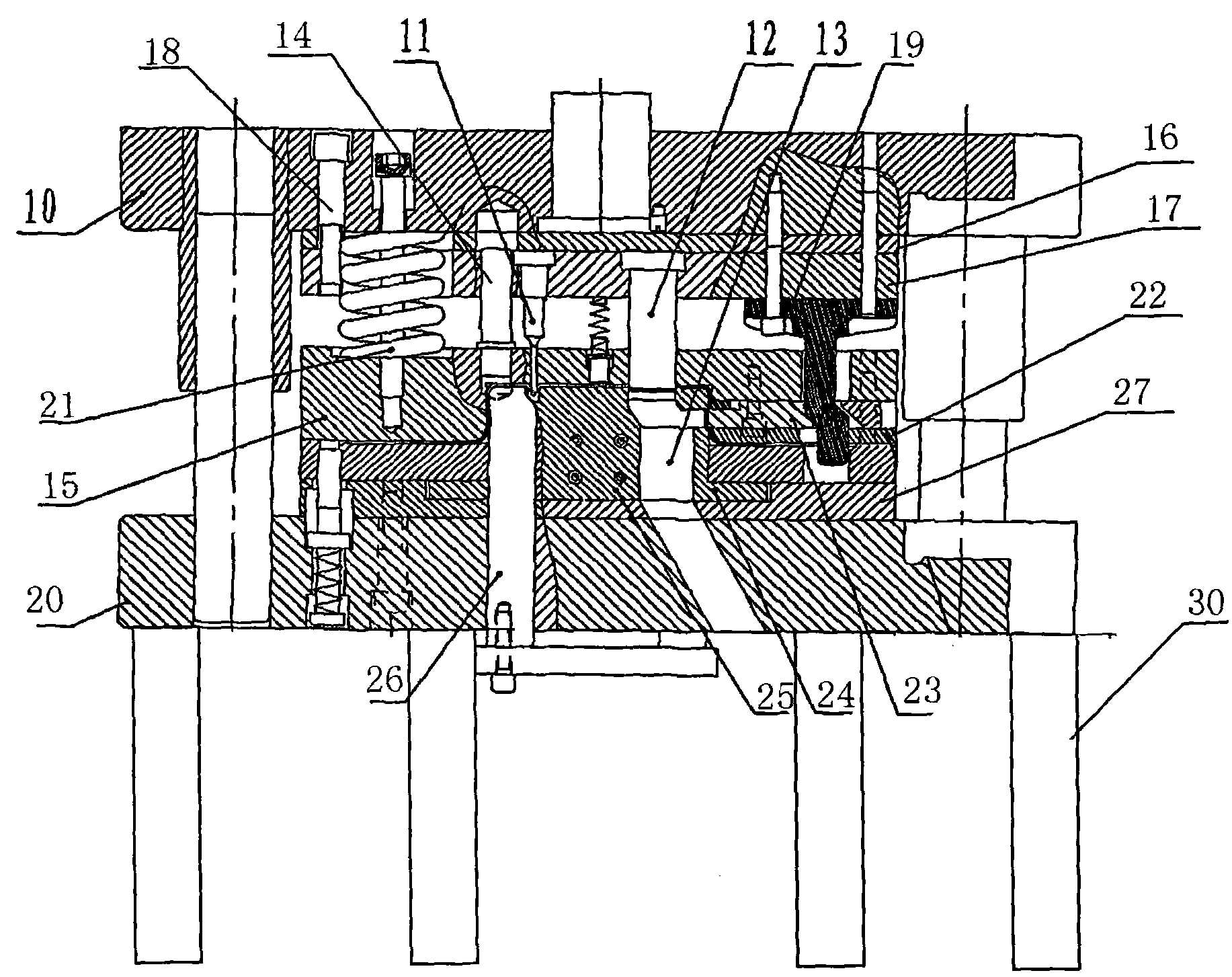

[0019] Referring to the figure, the automotive wire harness stamping die of the present invention includes an upper mold base 10 connected to a punch press and a lower mold base 20, a punch fixed on the lower mold base 20 and a die 15 fixed on the upper mold base 10, and a lower mold base 15. Die foot 30 is installed at the bottom of 20, and described punch is by punch insert 25 and the shaping punch 26 that is used for molding head U-shape to form the mosaic structure, after finishing deep-drawing, shaping punch 26 passes through with The air cushion device is connected, relying on the air cushion of the press to realize the shaping of each fillet of the part; the force required for its work is provided by the air cushion at the bottom of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com