Automatic lifting system

A technology of automatic lifting and lifting device, applied in the direction of lifting frame, lifting device, etc., can solve problems such as increased maintenance cost, complex structure, and device quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with preferred embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

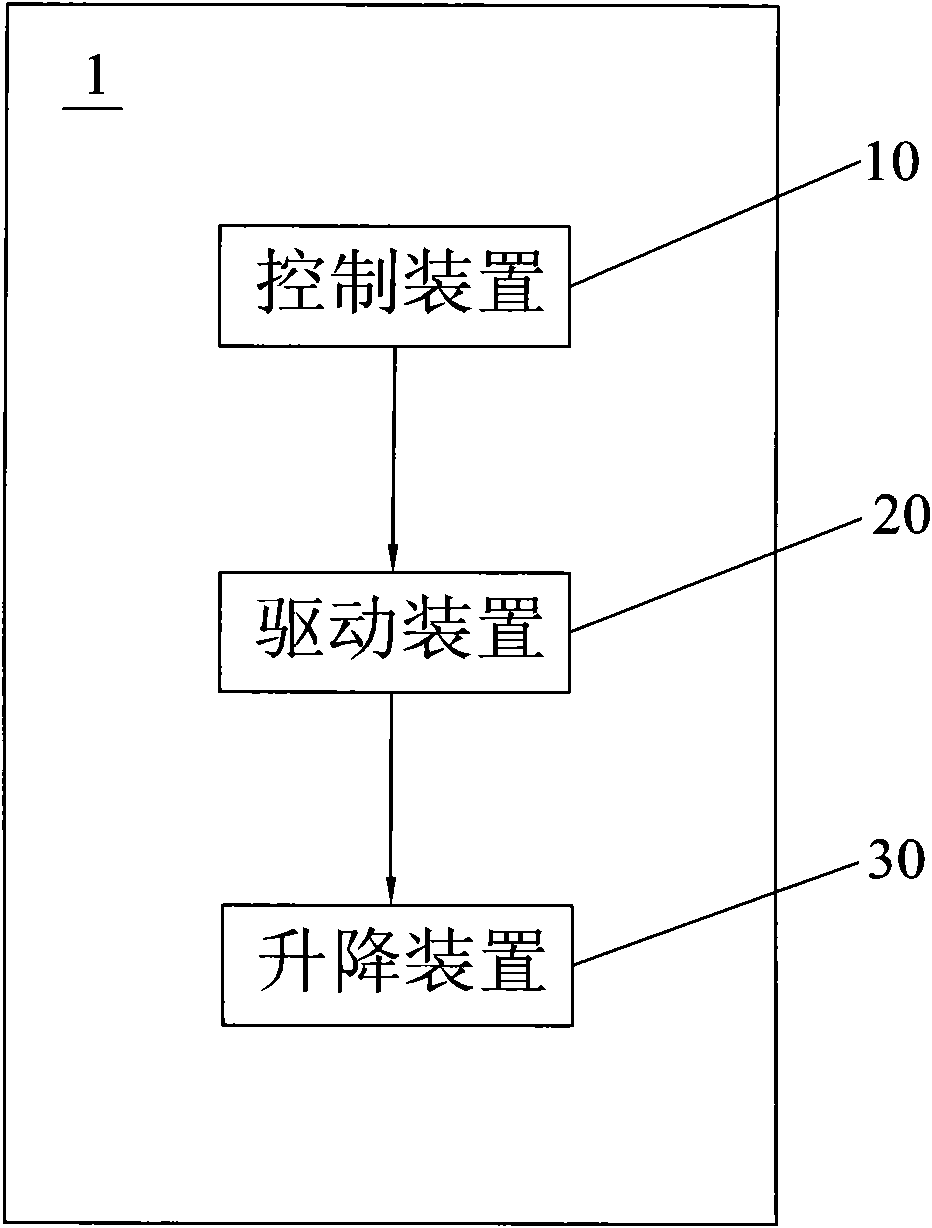

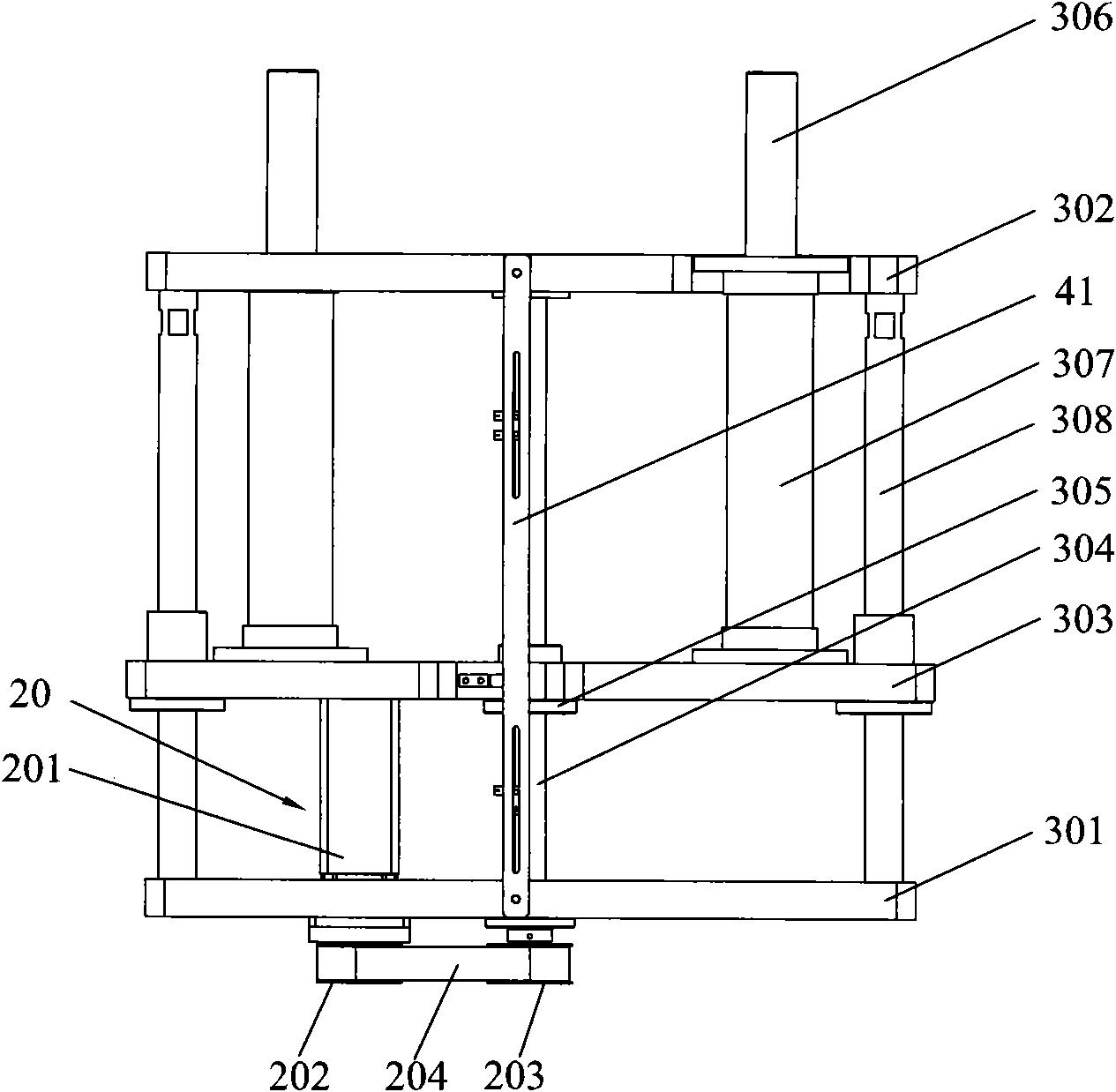

[0018] Please refer to figure 1 and figure 2 , The automatic lifting system 1 of the present invention includes a control device 10 , a driving device 20 and a lifting device 30 . The lifting device 30 is connected to an external workbench (not shown), the control device 10 is electrically connected to the driving device 20, and the control device 10 drives the driving device 20 so that the lifting device 30 drives the external workbench to perform linear reciprocating motion. The components and control methods of the automatic lifting system 1 of the present invention will be described in detail below.

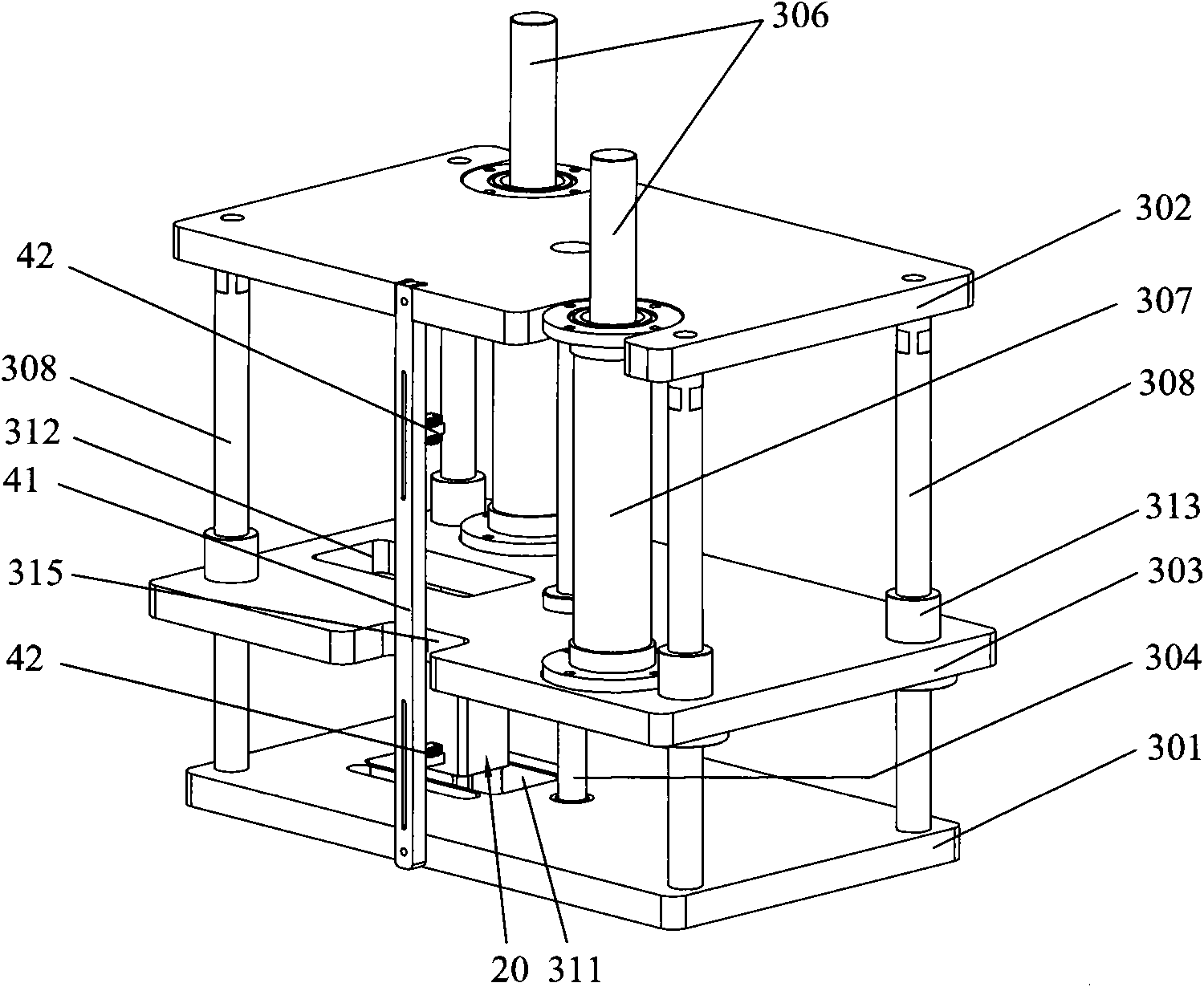

[0019] Such as Figure 2-4 As shown, the lifting device 30 includes a first fixed plate 301 , a second fixed plate 302 , a movable plate 303 , a lead screw 304 , a lead scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com