Welding-free cutting bit

A welding-free, pick-picking technology, applied in the field of pick-picking, can solve the problems of energy waste, borax dust and smoke, tearing, etc., to avoid welding process, ensure impact resistance, and facilitate reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

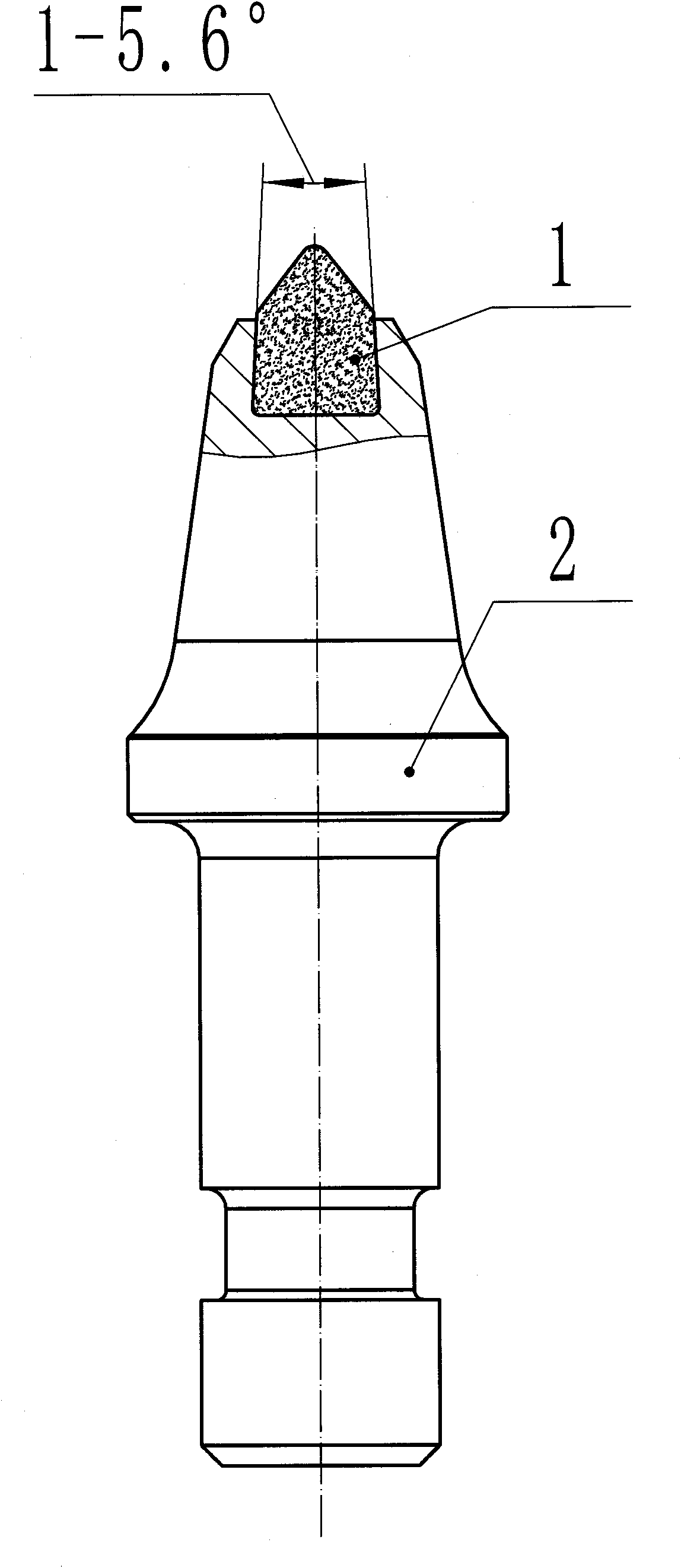

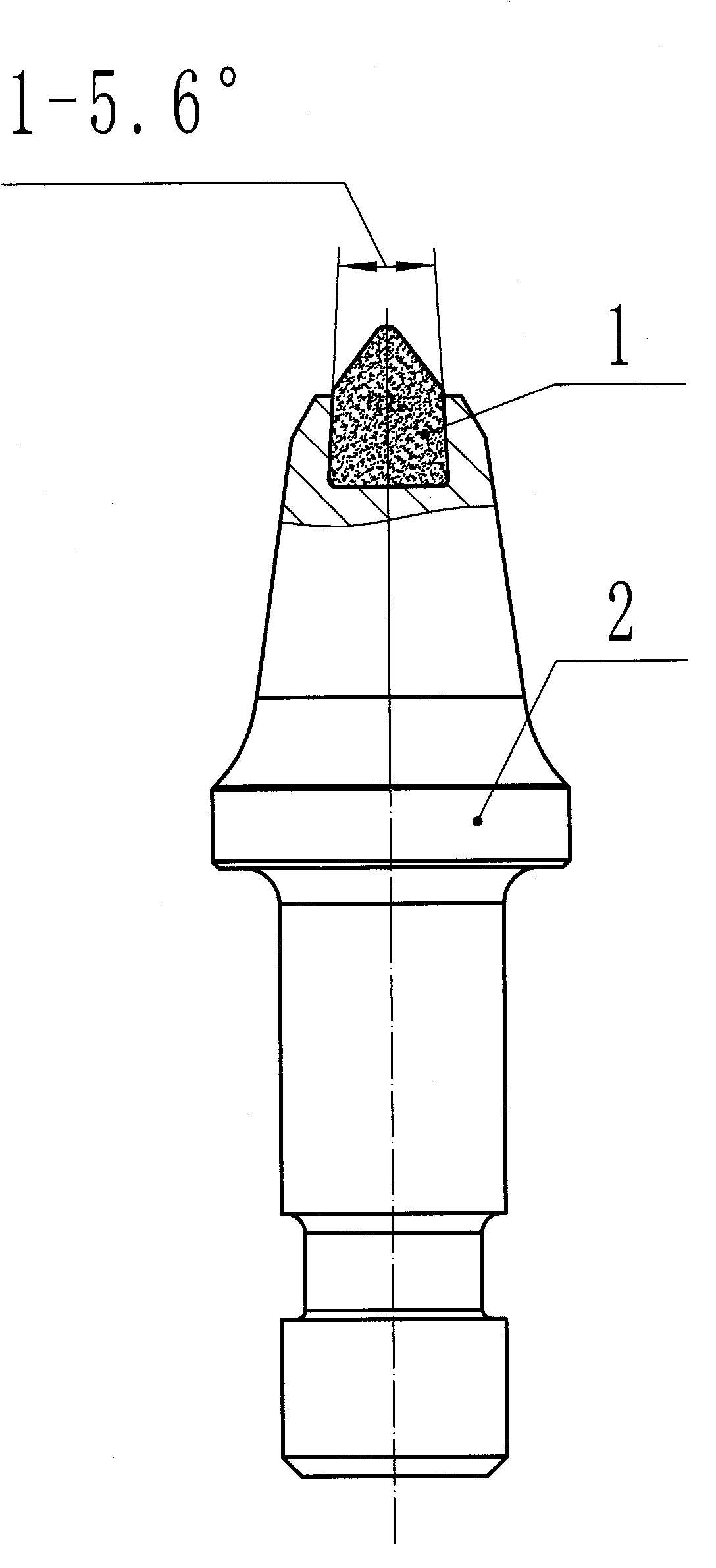

[0010] The welding-free pick consists of 2 pick bodies and 1 carbide head fixed on the head of the pick body; the working part of 1 carbide head is a cone with a cone angle of 130°, and the installation of 1 carbide head The pressing part is a cone, the cone angle is 1.0°, the bottom plane of the 1 carbide head is smooth, and its surface roughness is ≤Ra1.6μm. 2. The mounting hole on the head of the pick body is a conical hole with the same shape as the mounting and pressing part of the 1 carbide head, and all surfaces of the mounting hole are in close contact with all surfaces of the mounting and pressing part of the 1 cemented carbide head.

Embodiment 2

[0012] The welding-free pick consists of 2 pick bodies and 1 carbide head fixed on the head of the pick body; the working part of 1 carbide head is a cone with a cone angle of 60°, and the installation of 1 carbide head The pressing part is a cone with a cone angle of 5.6°; the mounting hole on the head of the 1 pick body is a conical hole with the same shape as the mounting pressing part of the 2 hard alloy head, and all surfaces of the mounting hole are consistent with the 1 hard alloy head All sides of the mounting press fit snugly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com