Nonspherical absolute measuring system based on multiwave front lens compensator

An absolute measurement and compensator technology, which is applied to aspheric absolute measurement systems and measurement fields, and can solve the problems of complex measurement process and data processing of aspheric absolute measurement methods, influence of lithography structure error detection results, and failure to meet common optical path conditions. , to improve the detection accuracy of the system, ensure the calibration accuracy, and achieve the effect of a large scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

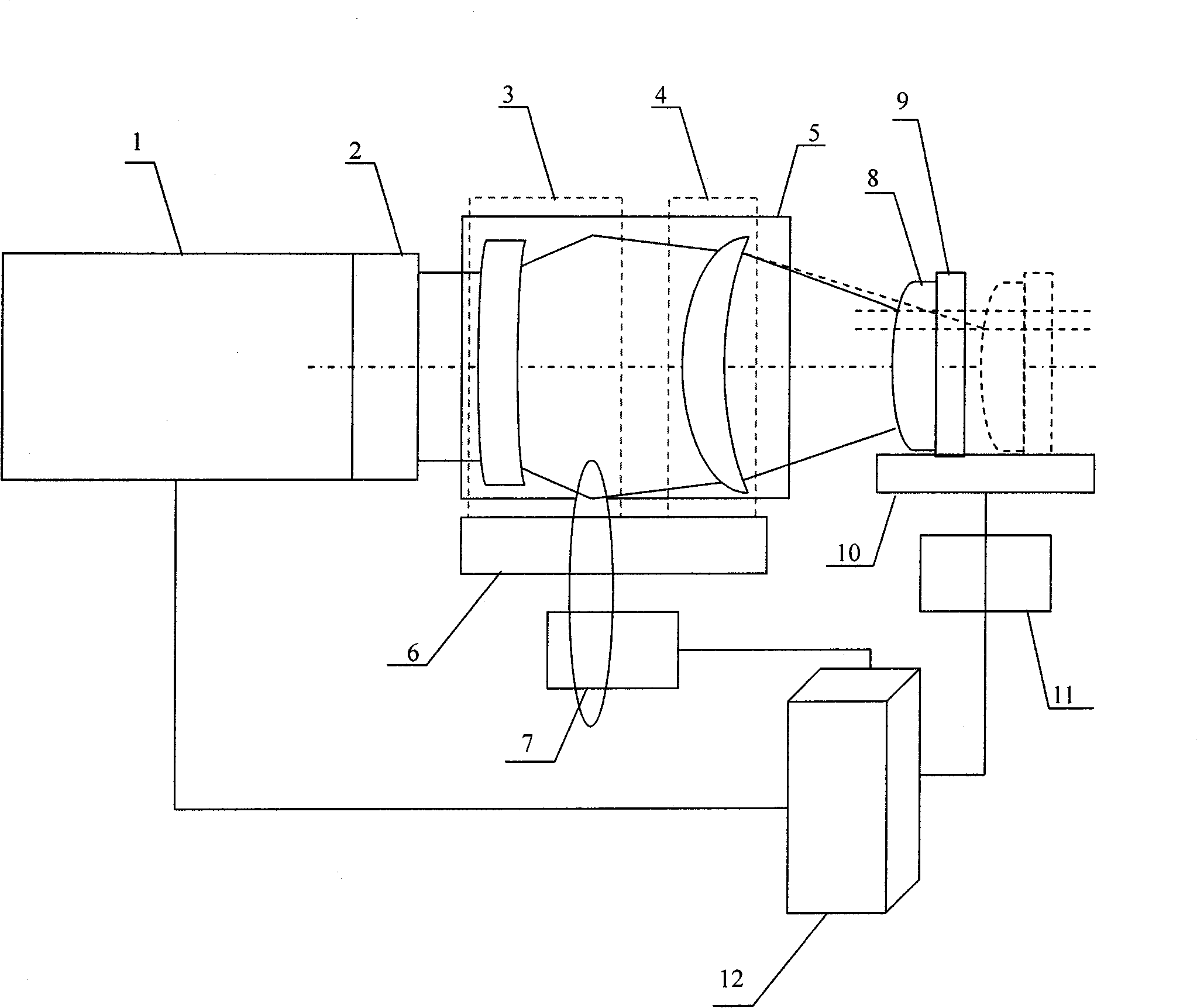

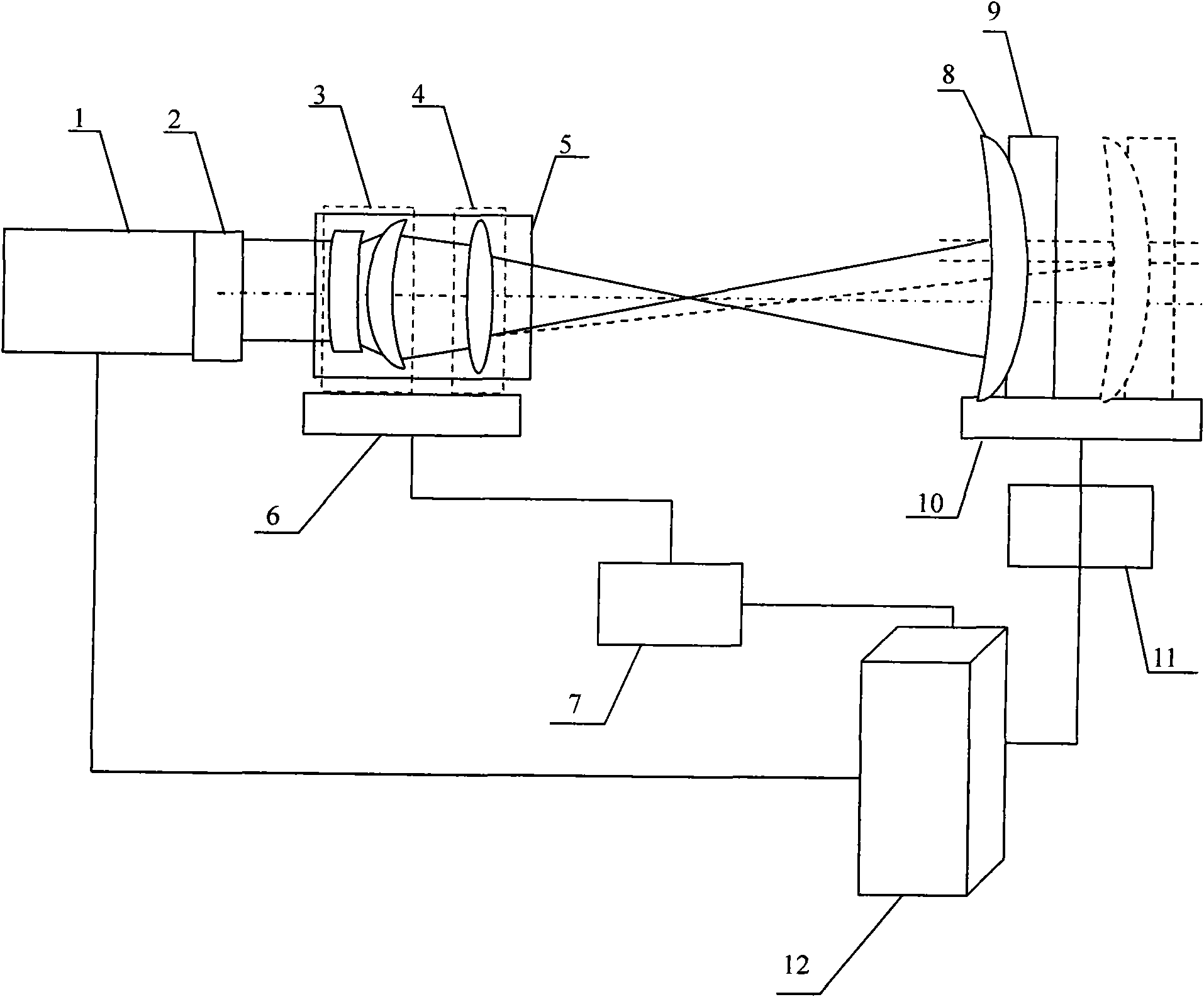

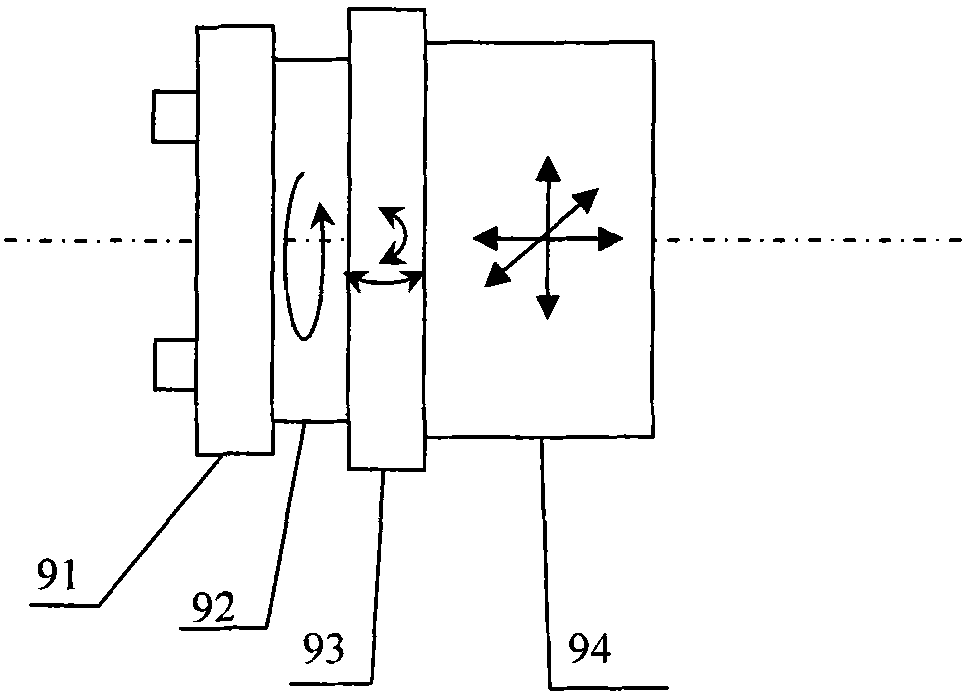

[0020] figure 1 is an absolute measurement system for aspheric surfaces based on multi-wavefront lens compensators for convex aspheric surface detection, figure 2 It is a schematic diagram for detecting a concave aspheric surface, and the absolute measurement system for detecting a concave aspheric surface and a convex aspheric surface of the present invention has the same structure except the multi-wavefront lens compensator. like figure 1 and 2 As shown, the aspheric absolute measurement system based on the multi-wavefront lens compensator includes a phase-shift interferometer 1, a standard lens 2, a multi-wavefront lens compensator 5 composed of multiple optical elements or element groups 3, 4, and an electrical The control adjustment device 6 and the electronic control adjustment device driver 7, the measured aspheric optical element 8, the six-dimensional adjustment frame 9, the electronic control translation stage 10 and the electric control platform driver 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com