Exposing machine and exposing method thereof

An exposure machine and exposure chamber technology, applied in the field of exposure and development technology, can solve the problems of short bulb life, increased production cost, and increased bulb replacement frequency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

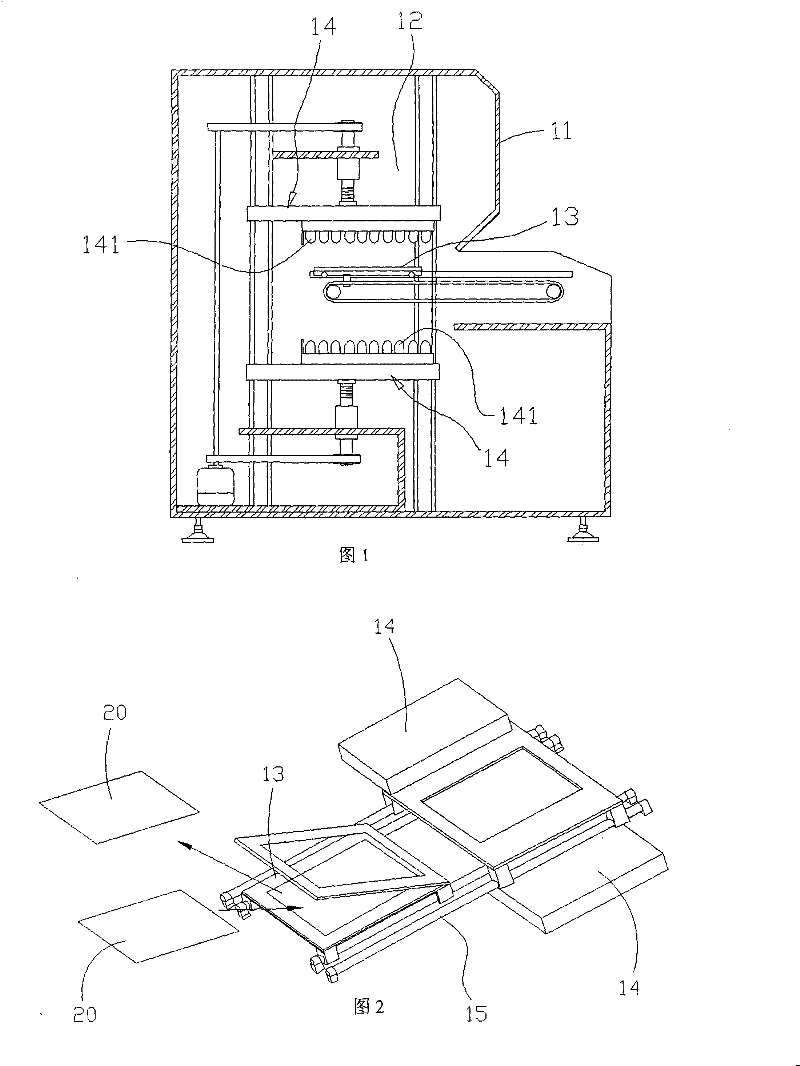

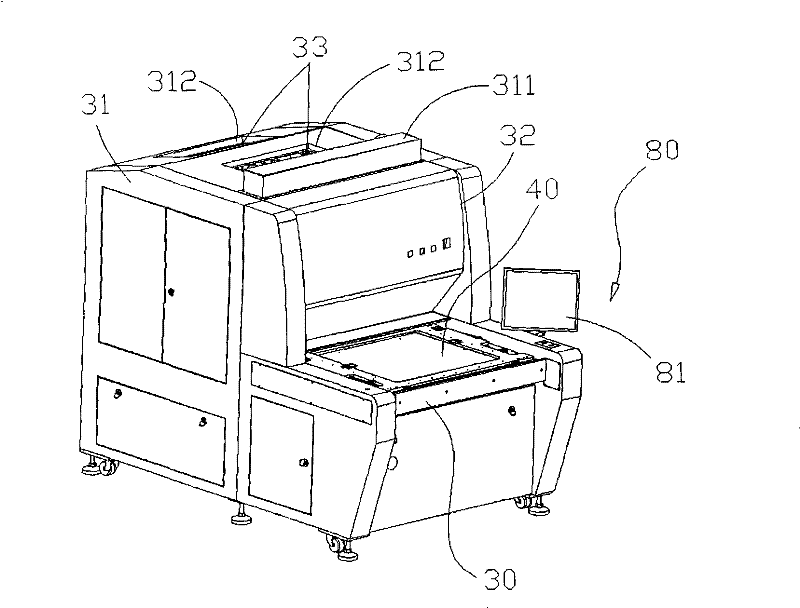

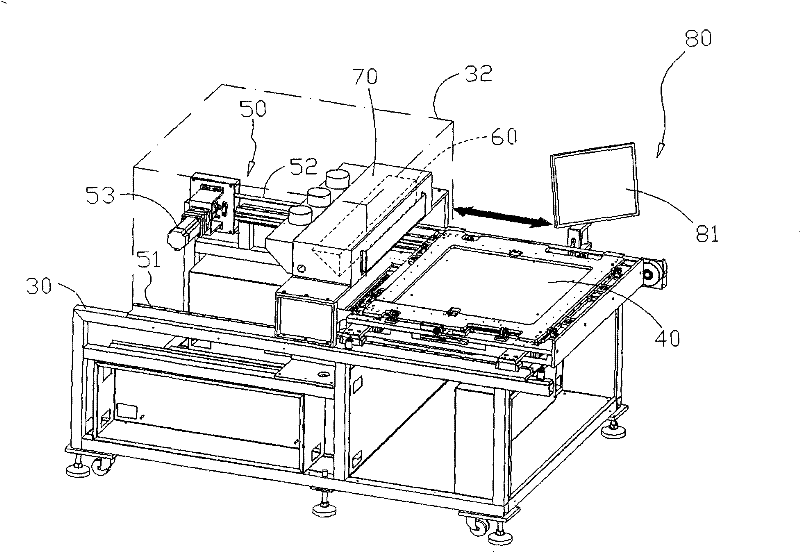

[0043] The features of the present invention can be clearly understood by referring to the detailed description of the drawings and embodiments of the present invention.

[0044] The present invention aims to provide an exposure machine that is less likely to generate heat accumulation and can relatively reduce equipment volume and cost, and an exposure method related thereto; the exposure method first generates at least one self-exposure inside an exposure chamber of the exposure machine The strip light source illuminated above the moving stroke of the platform or from the bottom of the moving stroke of the exposure platform toward the moving stroke of the exposure platform; and then equipped with the exposure platform of the exposure machine to receive the at least one strip light source in a way of relative displacement with the at least one strip light source at a predetermined speed. The irradiation of the light source further completes the exposure and development of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com