Wind-assisted braking system for automobile

A technology for auxiliary braking and automobiles, which is applied in the directions of brakes, braking components, vehicle components, etc., can solve the problems of high manufacturing cost, reduce the use space of the vehicle body, and increase the maintenance cost, and achieve low manufacturing cost, reliable operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

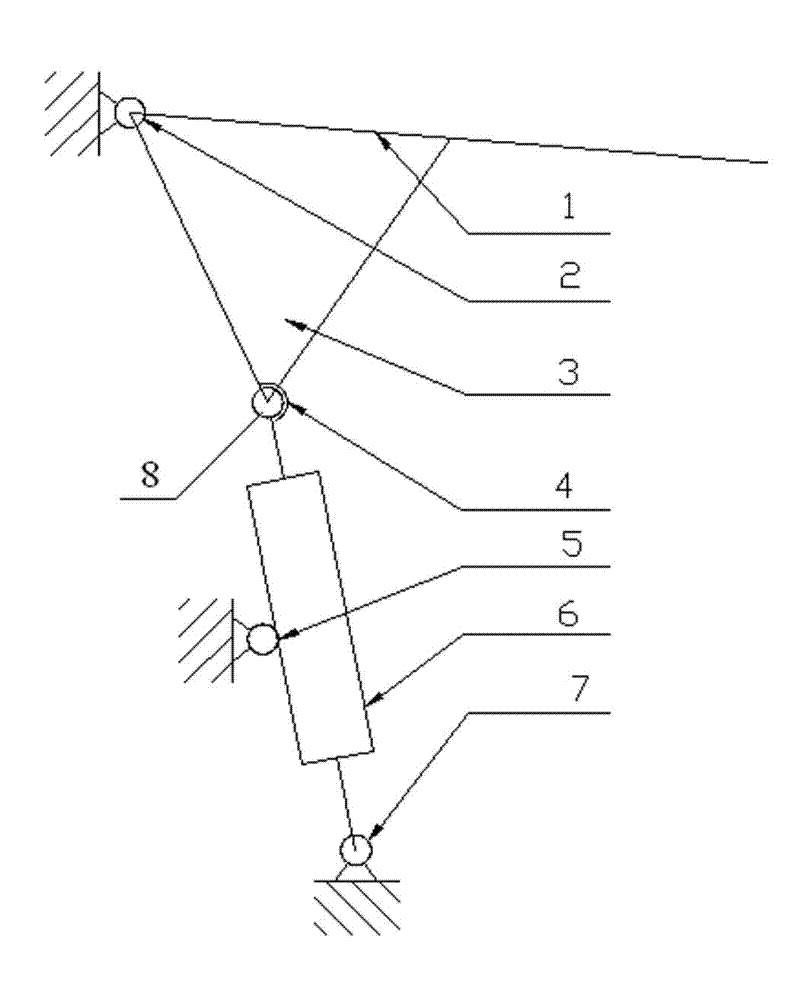

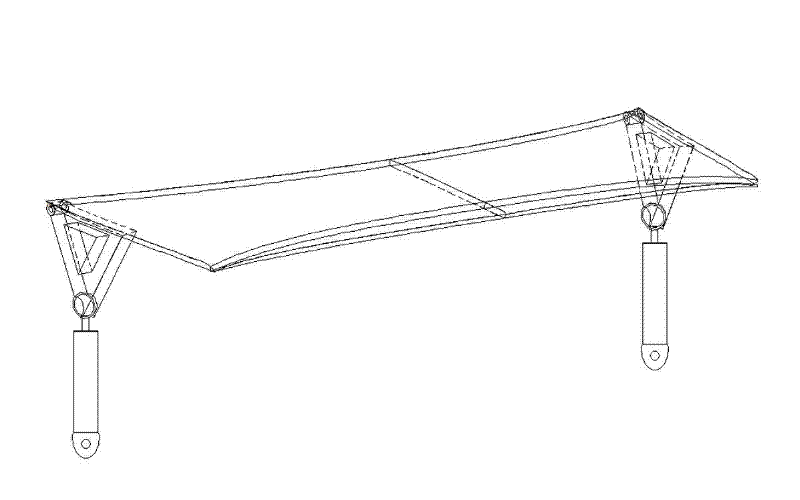

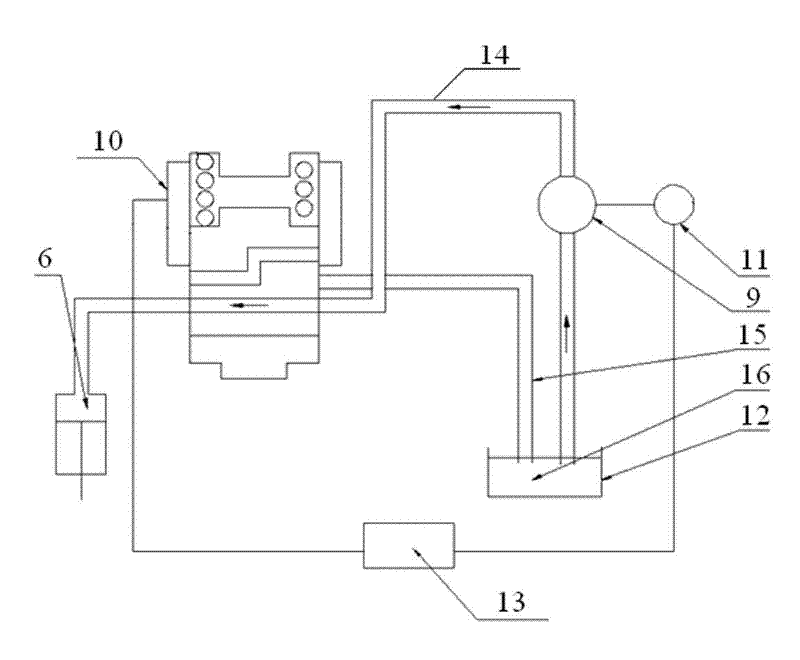

[0020] With reference to the accompanying drawings, this embodiment includes an auxiliary brake flap 1 hidden on the trunk of the car, one end of the auxiliary brake flap 1 is hinged on the lower frame of the rear windshield of the car, and the two sides of the auxiliary brake flap 1 are Fixed on two triangular brackets 3, one side of the triangular bracket 3 is fixedly connected with the auxiliary brake wing 1, the auxiliary brake wing 1 and the triangular bracket 3 share the hinge point I2 with the trunk cover of the car, and are connected with the auxiliary brake wing The hemispherical socket 4 on one corner of the triangular bracket 3 opposite to the plate 1 is connected with the ball head 8 at one end of the piston of the hydraulic cylinder 6, and the lower part of the hydraulic cylinder 6 is fixed and hinged to the bottom of the trunk through the hinge point II7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com