Processing method for hot-dip galvanized sheet used by automobile

A technology of hot-dip galvanized sheet and processing method, which is applied in the direction of hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problems of zinc pump corrosion, unreasonable, and affecting the production efficiency of hot-dip galvanized sheet, and achieve The effect of avoiding missed plating and ensuring surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

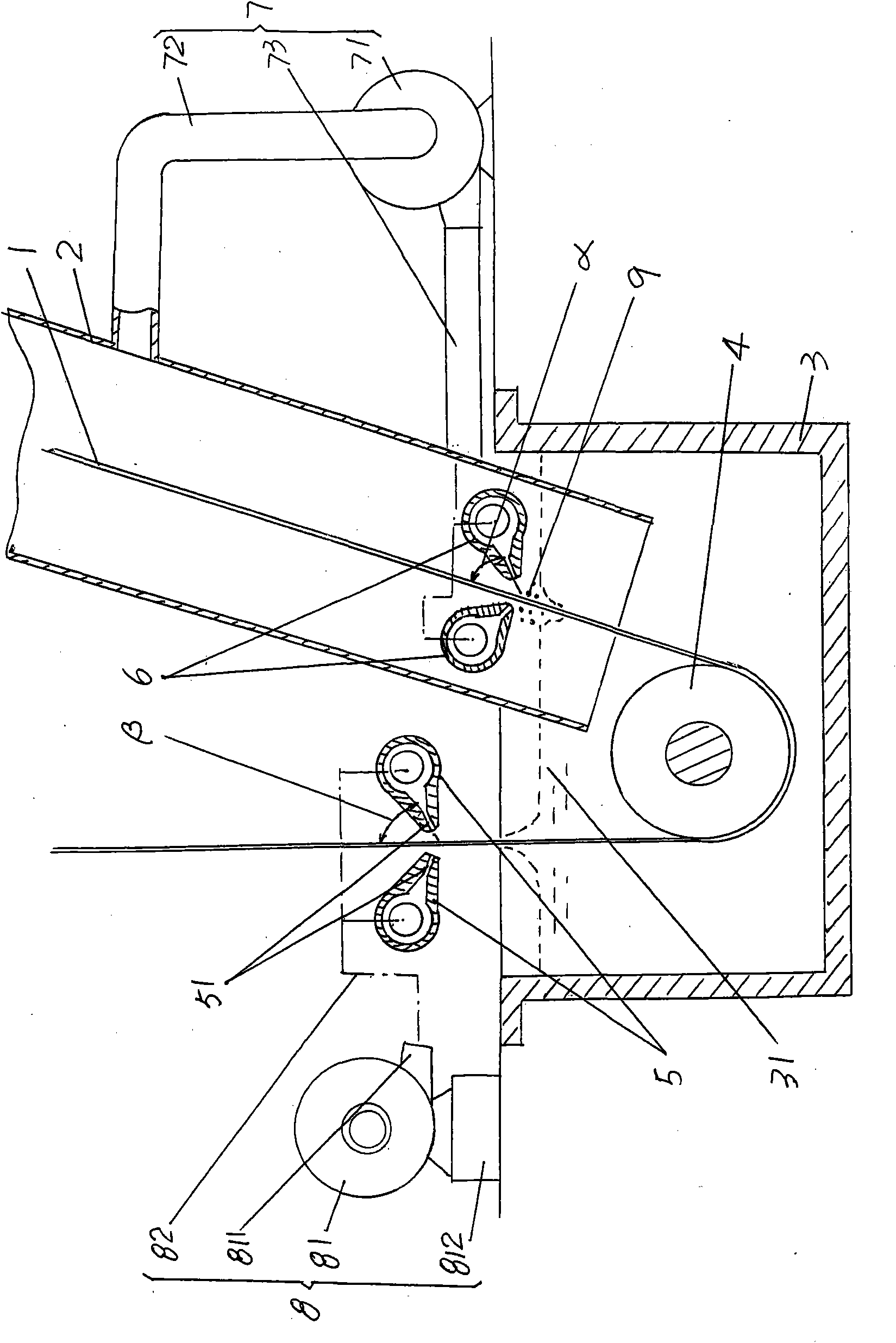

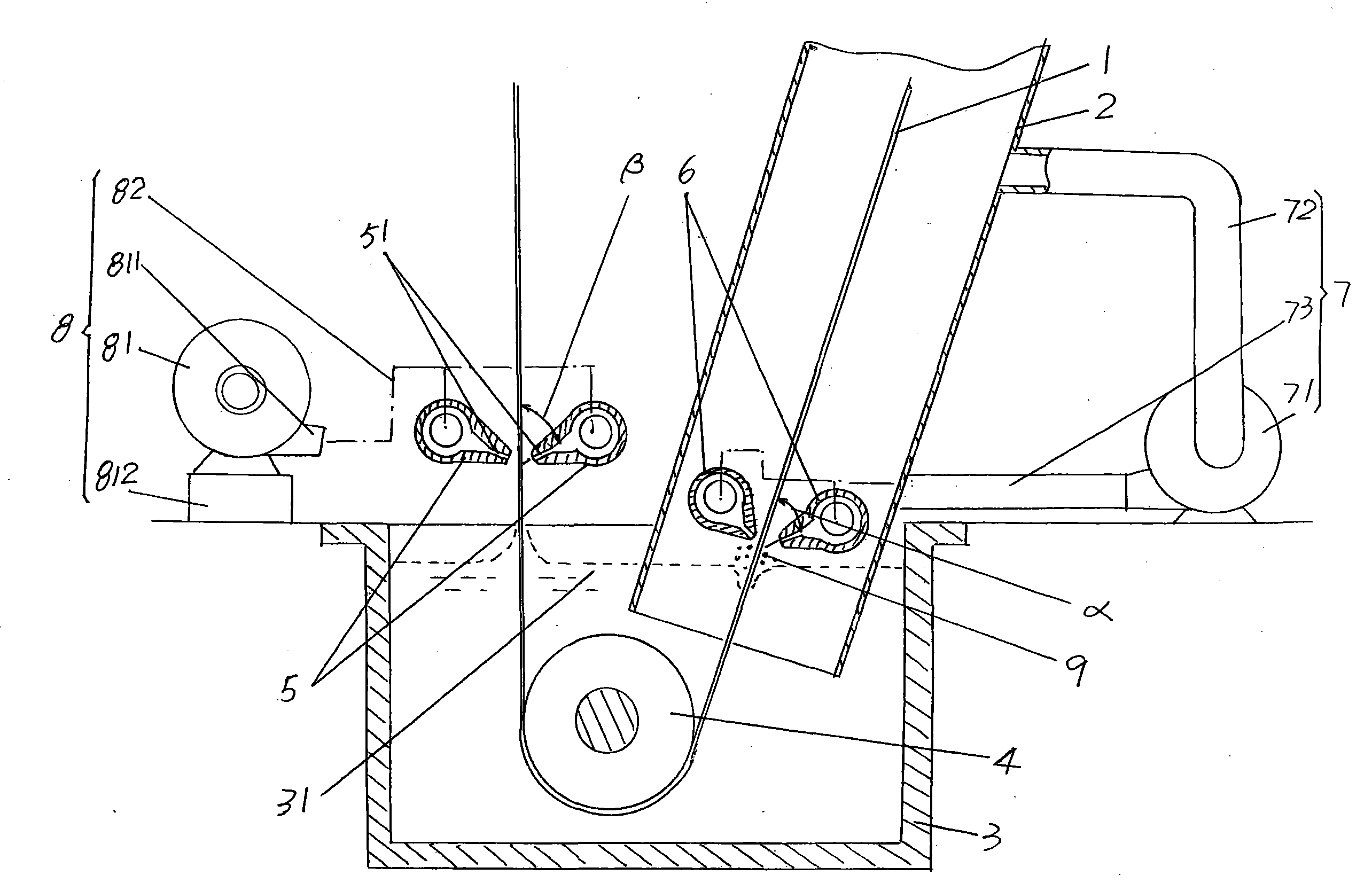

[0021] Please combine figure 1 , first, enter the furnace nose 2 in the zinc pot 3 filled with the zinc liquid 31 under the condition that the steel strip 1 is in a closed state, and set a blower for blowing the zinc liquid surface at a position corresponding to the top of the zinc liquid level. A pair of first air knives 6 each having a first blowing port 61, the length of a pair of first air knives 6 should satisfy the width of ≥ steel strip 1, and the first blowing port 61 of the first air knife 6 is in an inclined state Align the zinc liquid level, more specifically, maintain a first angle α between the first blowing port 61 and the steel strip 1, the degree of the first angle α is preferably 10-60°, preferably 15° -55°, more preferably 30-45°, most preferably 45°, 45° is selected in this embodiment. Then, when a pair of first blowing ports 61 are blowing on the zinc liquid surface at the same time, the impurities on the zinc liquid surface surface can be blown away from ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap