Gasification combustion hydrolyzing auxiliary combustion device and method of pulverized coal

A technology of pulverized coal and combustion chamber, which is applied in combustion methods, burners for burning powder fuel, burners, etc., to achieve the effects of reducing flue gas emissions, wide application range, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

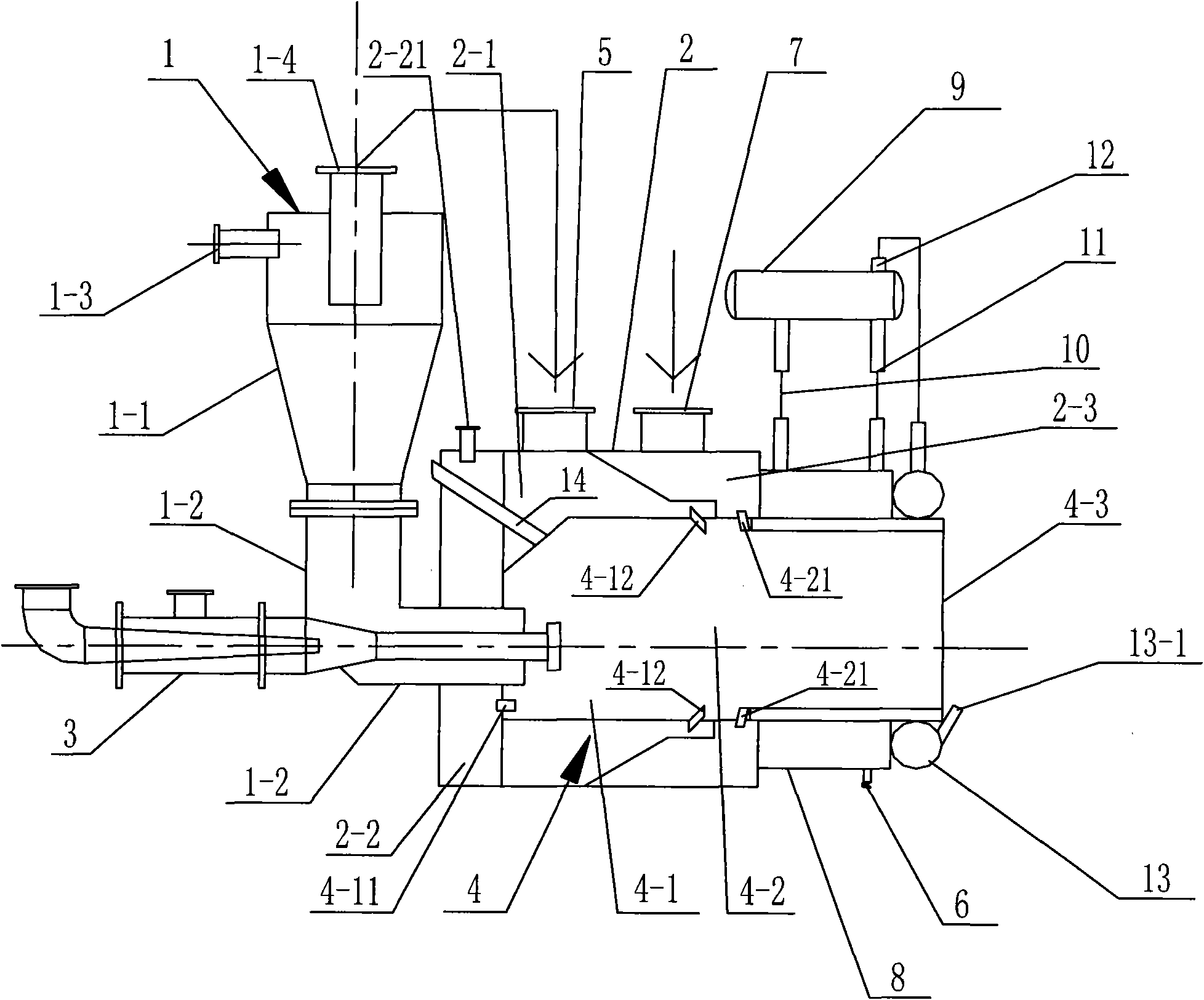

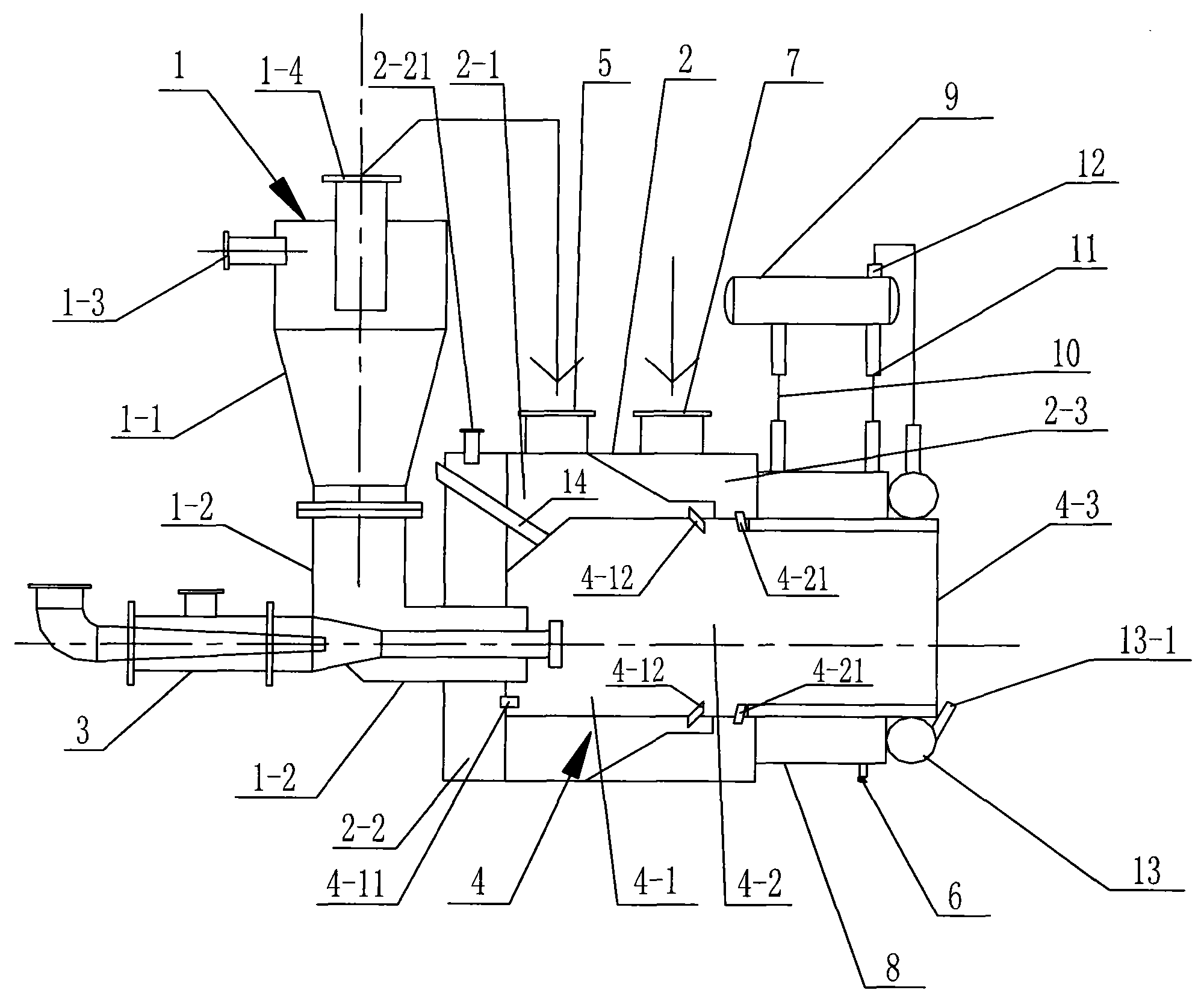

[0042] see figure 1 , a pulverized coal gasification combustion hydrolysis combustion-supporting device, comprising a pulverized coal thick-lean separator 1, a hydrolysis combustion-supporting device, and a gas fuel injector 3. The hydrolysis combustion aid has a housing 2 and a gasification combustion chamber 4, and a light phase pulverized coal chamber 2-1 and two combustion air chambers 2-2 are formed between the housing 2 and the gasification combustion chamber 4 , 2-3. Wherein, one combustion-supporting air chamber 2-2 is arranged at the inlet end of the gasification combustion chamber 4; the other is arranged on the right side of the light-phase pulverized coal chamber 2-1.

[0043] The gasification combustion chamber 4 has a plurality of light-phase pulverized coal channels 4-12 communicating with the light-phase pulverized coal chamber 2-1 and a plurality of channels 4-12 communicating with the combustion-supporting air chambers 2-2, 2-3. The air intake channel 4-11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com