High temperature solar tiled reflecting mirror array architecture

A mirror array and solar energy technology, applied in the field of high-temperature solar energy, can solve the problems of staying in the experimental stage, high cost, and difficulty in popularization and application, and achieve the effects of flexible rotation, long service life, and convenient expansion or reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and example. Parts of the present invention are purchased on the market.

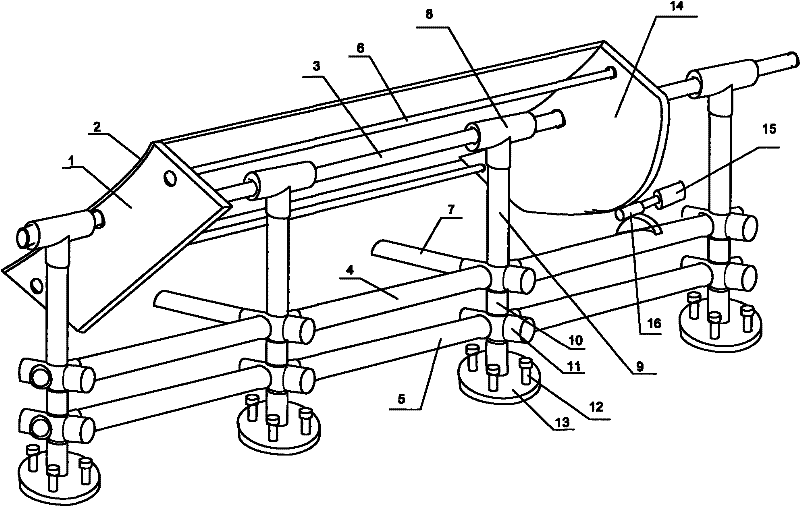

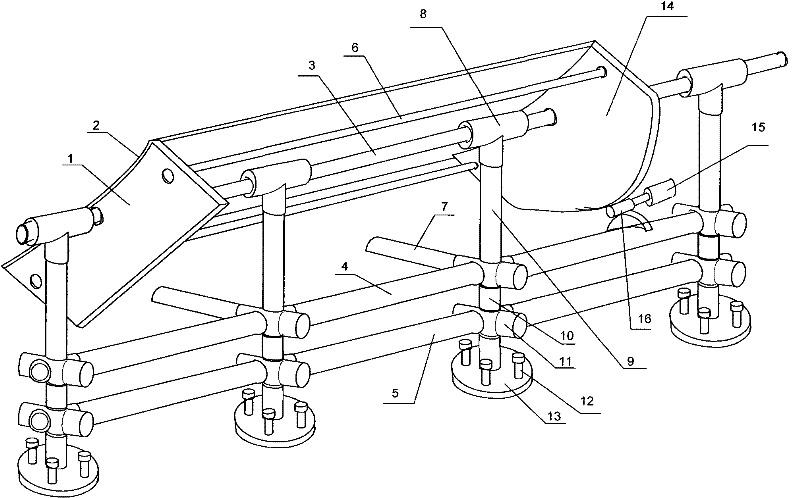

[0019] figure 1 It is a schematic diagram of the structure of a single support structure of the present invention, which is constructed of PVC plastic material pipe profiles.

[0020] The assembly process of the single support structure is as follows: first, install the base leveling fixing bolts 12 into the screw holes of the PVC flange base 13, insert the PVC support pipe 9 into the installation port of the flange base 13, Pack flat four-way connector 11 on the support pipe 9 of base 13, then pack PVC pipe profile flat four-way isolation liner 10 on it, then pack a flat four-way connector 11, and then press into the bearing The solar reflector linkage shaft bearing seat 8 made with the PVC profile plane tee connector is contained in the top, and like this, it is just structured into a reflector supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com