Vacuum valve quality detection platform

A technology of detection platform and vacuum valve, which is applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems of difficult real-time automatic detection, unsatisfactory detection accuracy, errors, etc., and achieve good real-time automatic detection performance, good Time-sharing control function, friendly man-machine interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further described, not limiting the scope of protection:

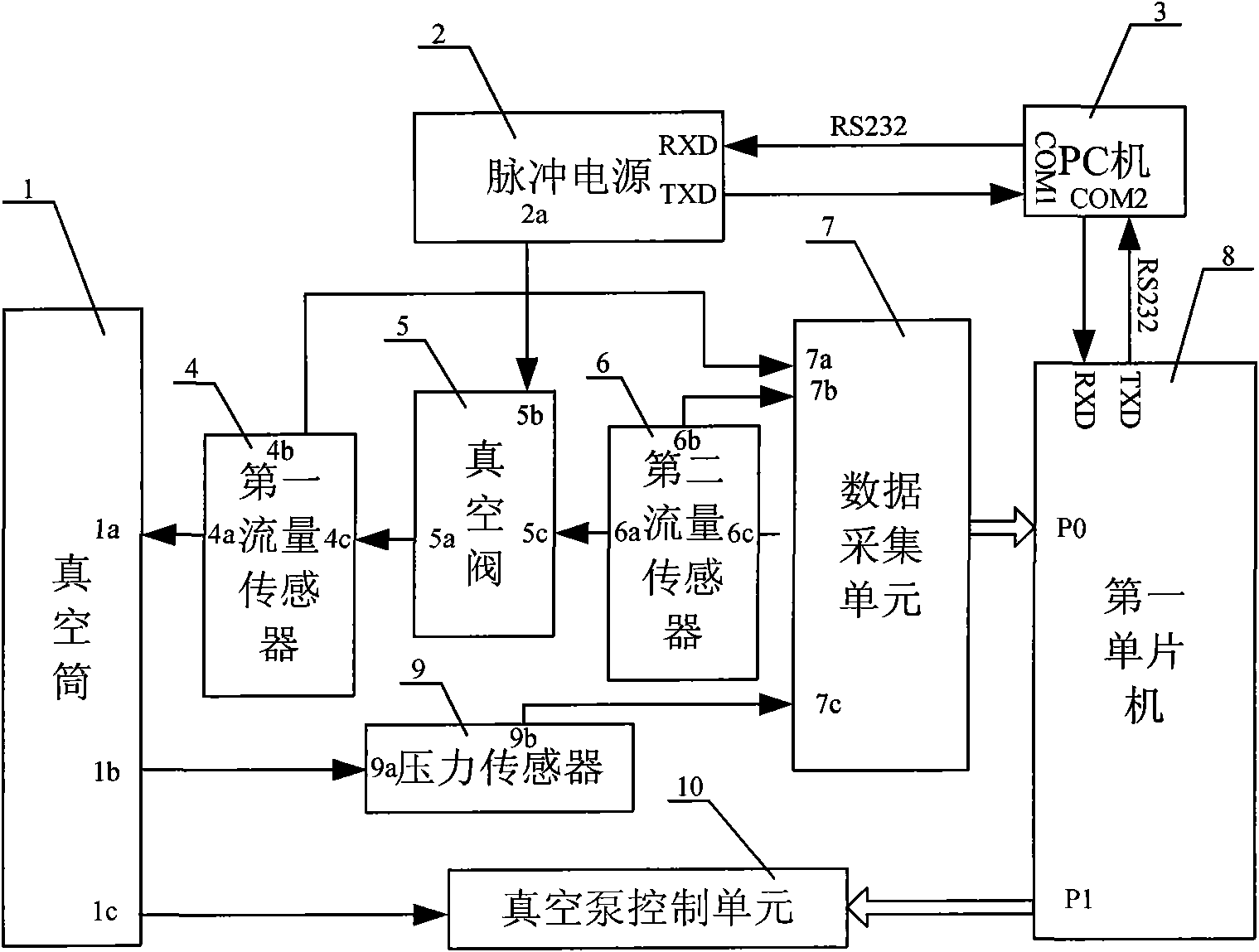

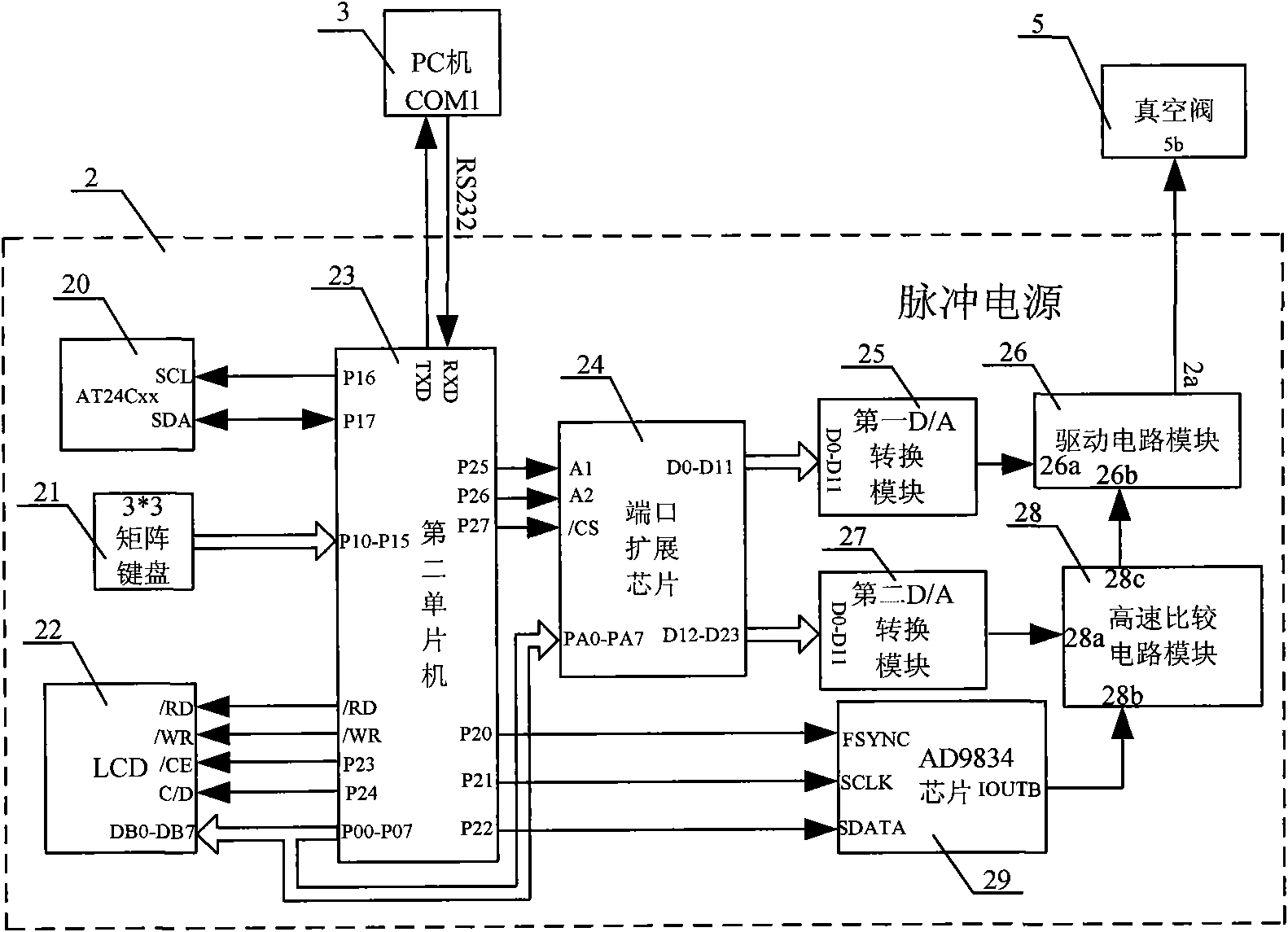

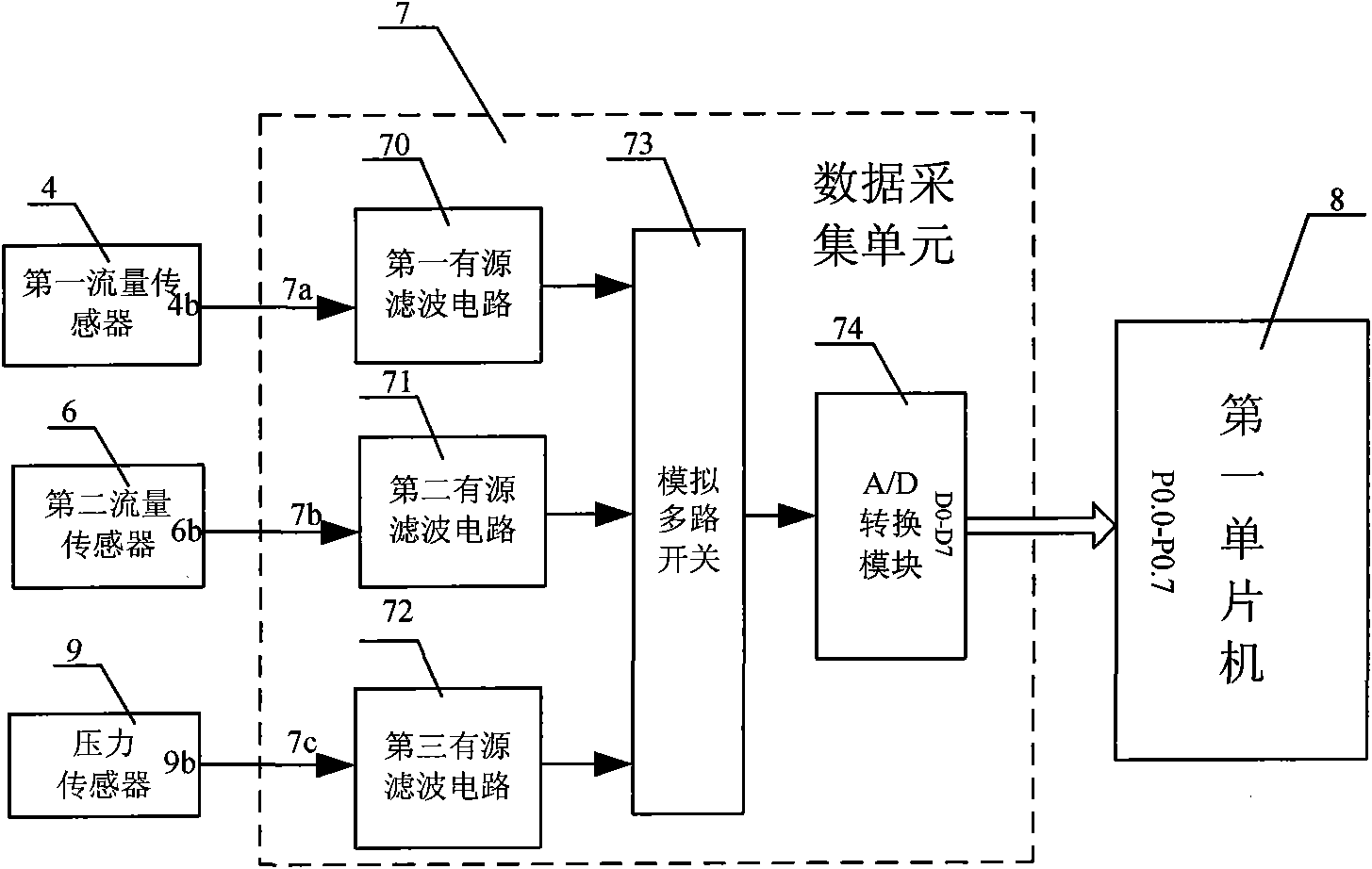

[0036] A quality inspection platform for vacuum valves: the platform is as figure 1 As shown, it includes a vacuum cylinder 1, a pulse power supply 2, a PC 3, a first flow sensor 4, a vacuum valve 5, a second flow sensor 6, a data acquisition unit 7, a first single-chip microcomputer 8, a pressure sensor 9 and a vacuum pump control unit 10 .

[0037] The air inlet 1a of the vacuum cylinder 1 communicates with the air outlet 4a of the first flow sensor 4 through the pipeline, the air outlet 1b of the vacuum cylinder 1 communicates with the air inlet 9a of the pressure sensor 9 through the pipeline, and the air suction port of the vacuum cylinder 1 1c communicates with the suction port of the vacuum pump control unit 10 through a pipeline.

[0038] The air inlet 4c of the first flow sensor 4 communicates with the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com