Satellite-type helical multi-core fiber optical micro-tweezers capable of achieving rotation of small particles and preparation method thereof

A multi-core optical fiber and tiny particle technology, applied in the field of optical fiber technology research, to achieve the effect of improving practicability, reducing damage, and capturing flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

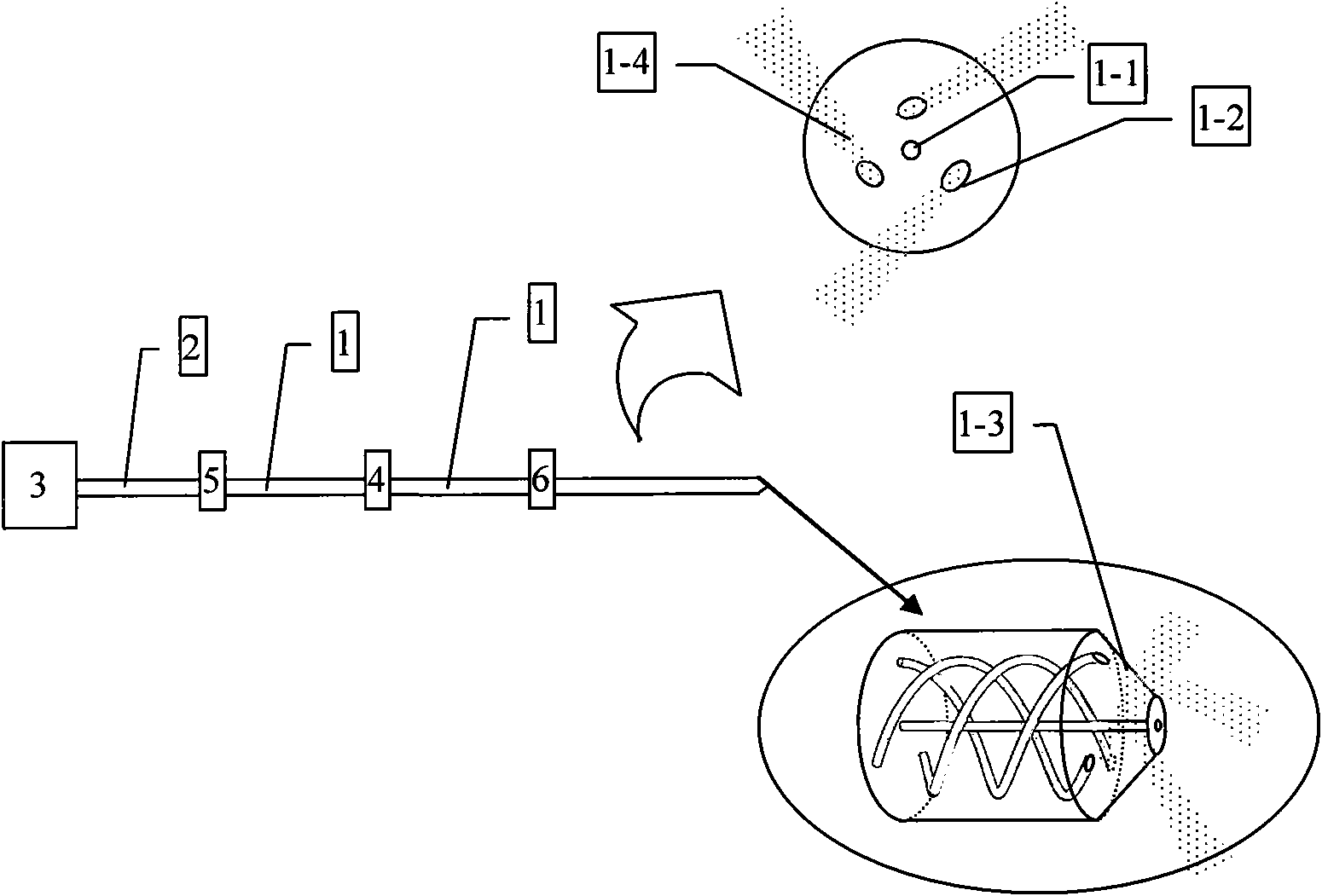

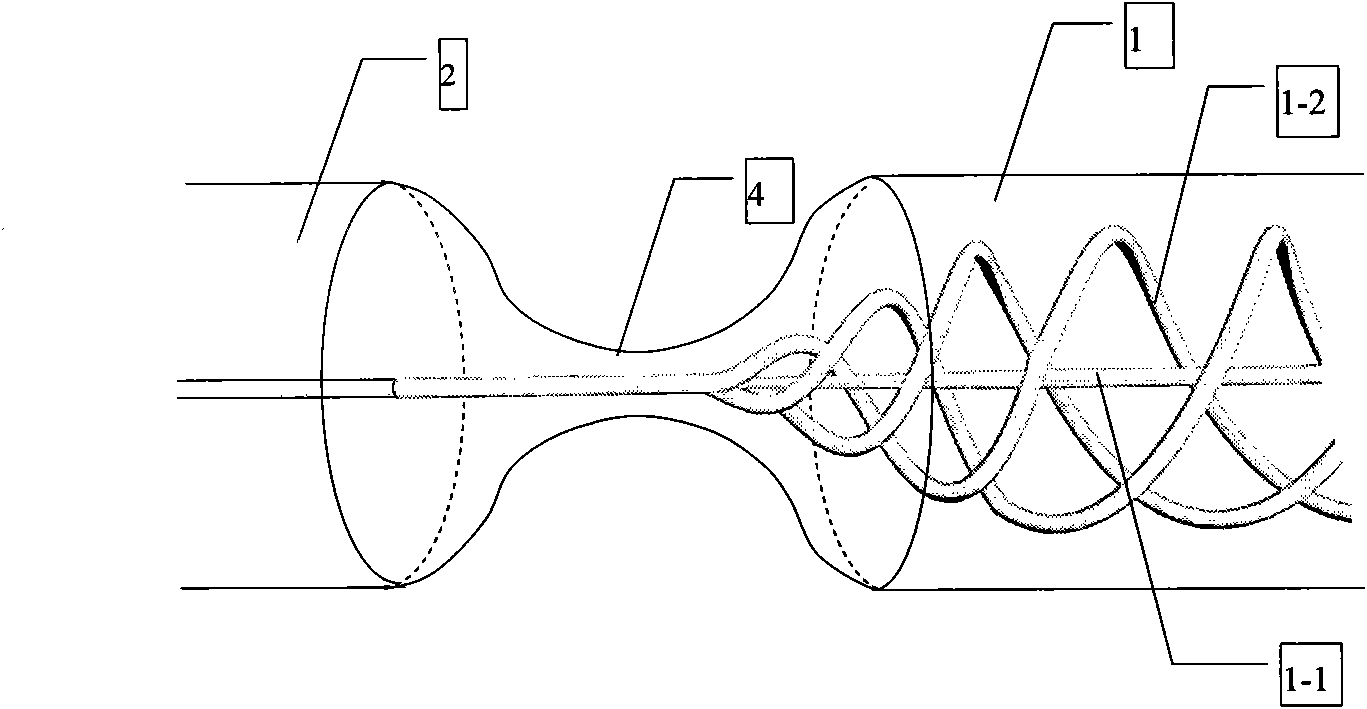

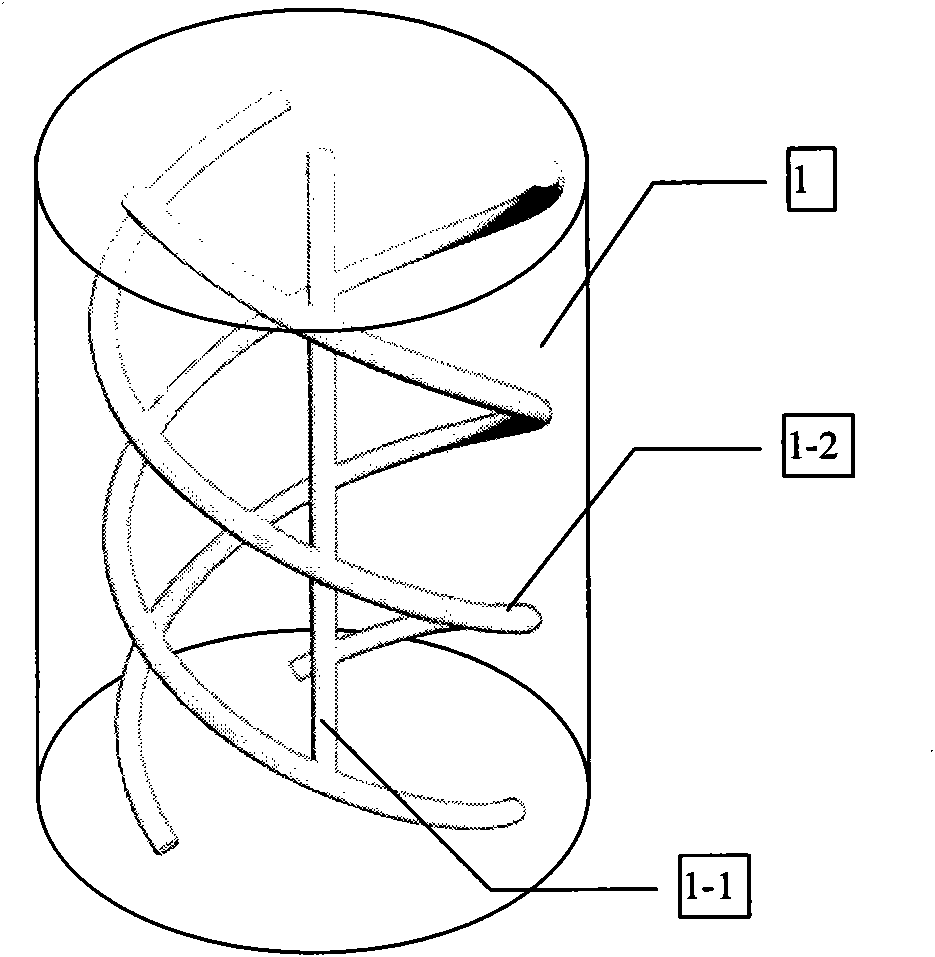

[0026] figure 1 Among them, 1 is the satellite spiral multi-core optical fiber, 1-1 is the core at the axis of the optical fiber, 1-2 is the satellite core of the optical fiber, and 1-3 is the cone prepared by the end of the satellite spiral multi-core optical fiber structure, the semi-cone angle α is controlled at π / 2-arcsin(n liquid / n core )<α<π / 2, 2 is the standard single-mode fiber, 3 is the laser light source, 4 is the optical path changing device, 5 is the direct coupling connection position between the standard single-mode fiber and the satellite spiral multi-core fiber, 6 is the satellite The position of the spiral multi-core optical fiber is thermally melted to pull the cone, so that a Mach-Zehnder interferometer is formed between 5 and 6, and the optical path difference between different fiber cores is changed by adjusting the optical path changing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com