Ultra-pure nonlinear control system and method for internal thermally coupled distillation column

An internal thermal coupling and nonlinear control technology, applied in the field of ultra-high-purity nonlinear control systems, can solve problems such as poor control effect and poor ability to suppress interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

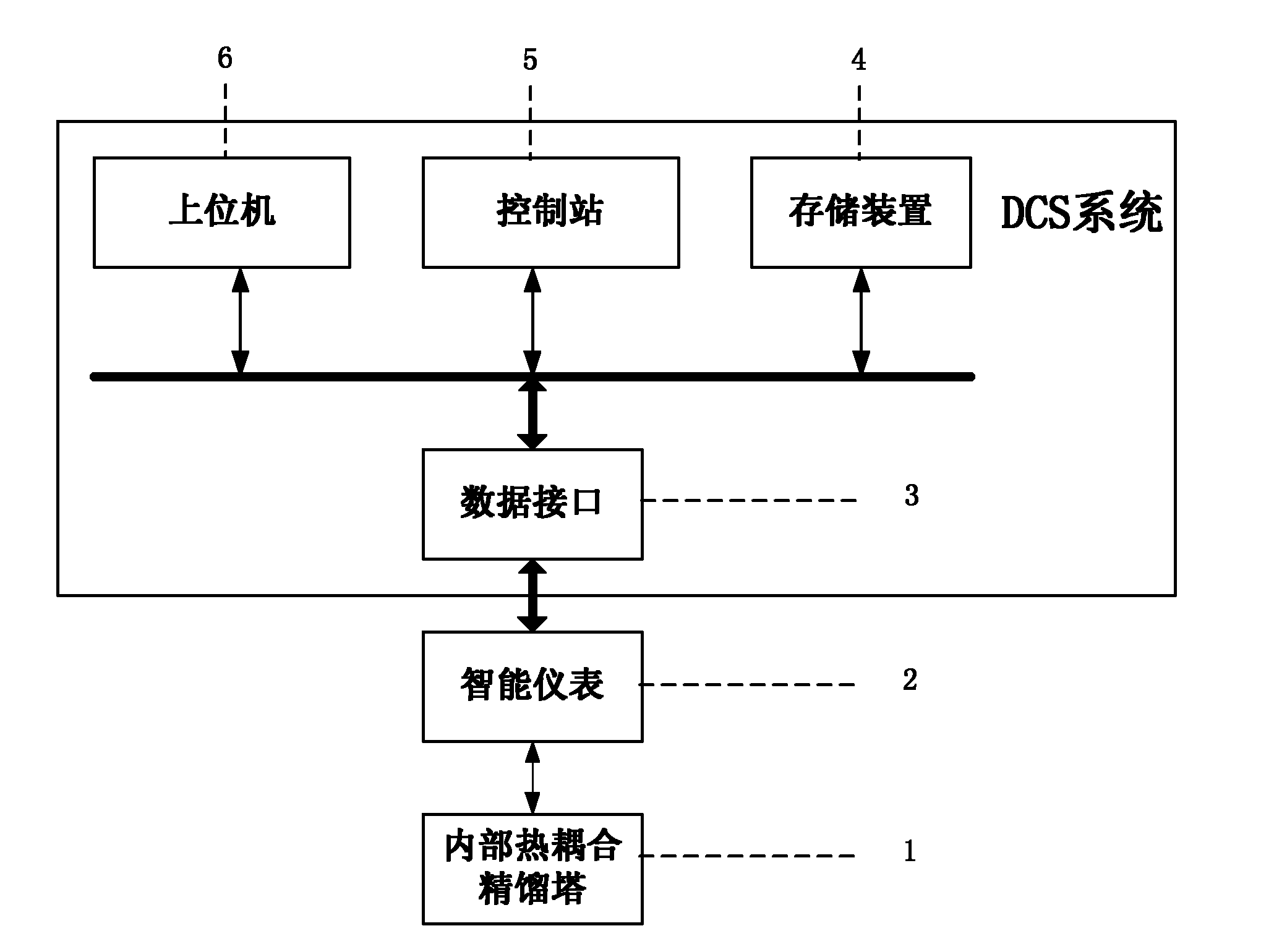

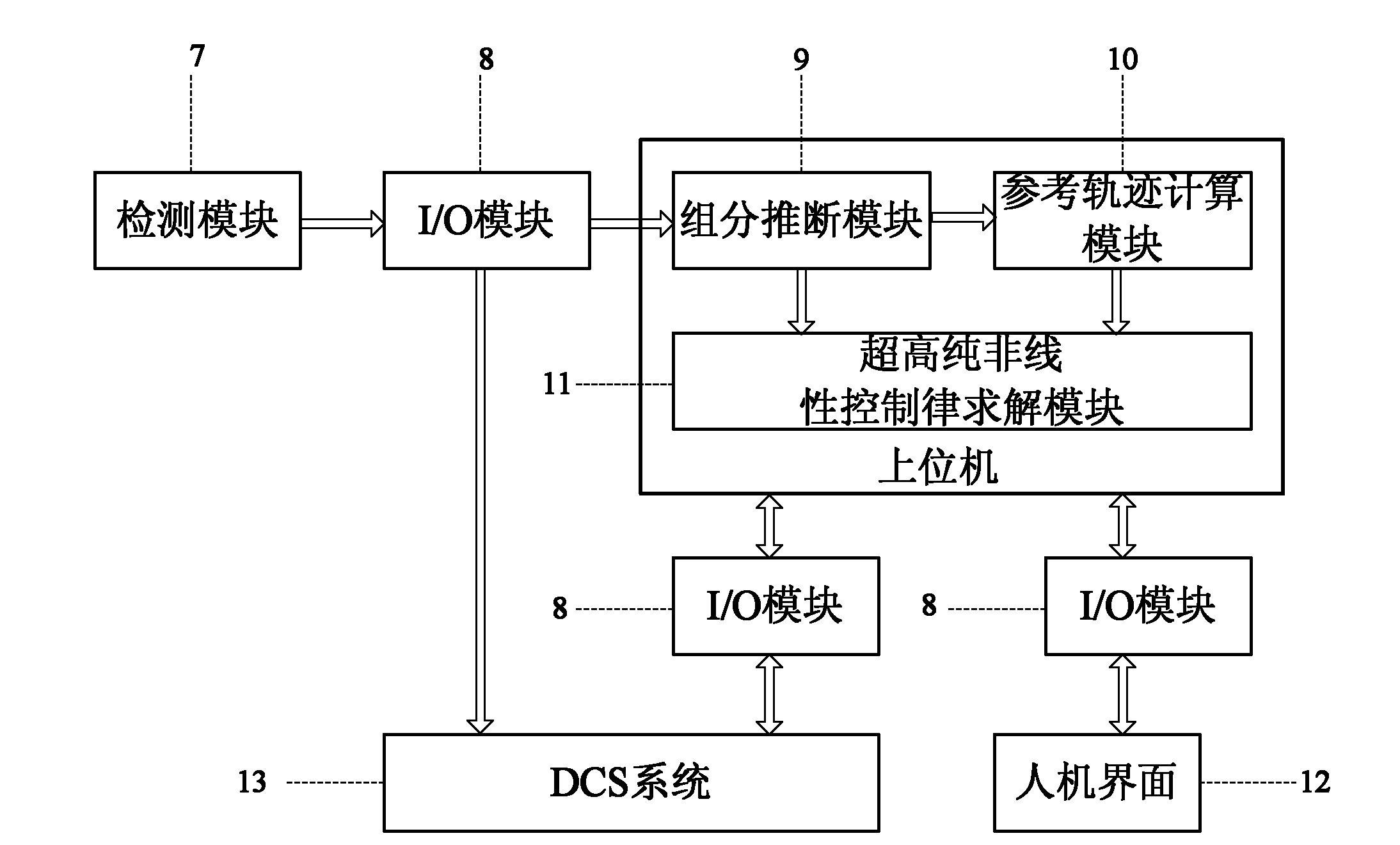

[0057] refer to figure 1 and figure 2 , an ultra-high-purity nonlinear control system for an internal thermally coupled rectification tower, the control system includes field intelligent instruments 2 and a DSC system 13 directly connected to the internal thermally coupled rectification tower, the DCS system 13 includes a storage device 4, a control station 5 and host computer 6, wherein, field intelligent meter 2 is connected with storage device 4, control station 5 and host computer 6 successively through field bus and data interface 3; The temperature and pressure data of the internal thermal coupling rectification column, the data interface is used to realize the function of the I / O module 8, that is, the input and output of data; the host computer includes an internal thermal coupling rectification column control for calculation and output An ultra-high-purity nonlinear controller for variable values, the ultra-high-purity nonlinear controller includes a component deduc...

Embodiment 2

[0080] refer to figure 1 and figure 2 , an ultra-high-purity nonlinear control method of an internal thermally coupled rectification tower, the control method comprising the following steps:

[0081] 1) Determine the sampling period, and compare the relative volatility α, the pressure of the stripping section P s , Antonie constants a, b, c are stored in the historical database;

[0082] 2) Set the control law parameter K12 , K 11 , K 10 , K 22 , K 21 , K 20 and the set value Y of the concentration of the vapor phase product at the top of the tower 1 * , the set value of the concentration of light components in the bottom liquid phase X n * ;

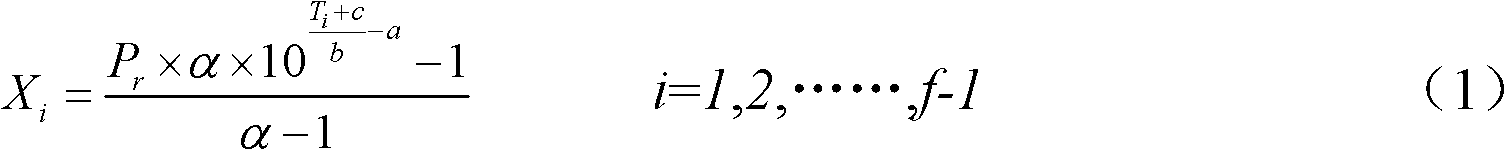

[0083] 3) Obtain the pressure P of the rectification section from the smart instrument r Pressure in the stripping section P s , and each tray temperature T i , to calculate the concentration of light components in the liquid phase, and use formula (1) (2) to get:

[0084] X i = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com