Aeroelastic stability fluid-structure interaction prediction method of turbo-machine changed interblade phase angles

A technology of aeroelastic stability and turbomachinery, applied in computing, special data processing applications, instruments, etc., can solve problems such as predicting the aeroelastic stability of turbomachinery blades, and achieve the effect of reducing calculation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

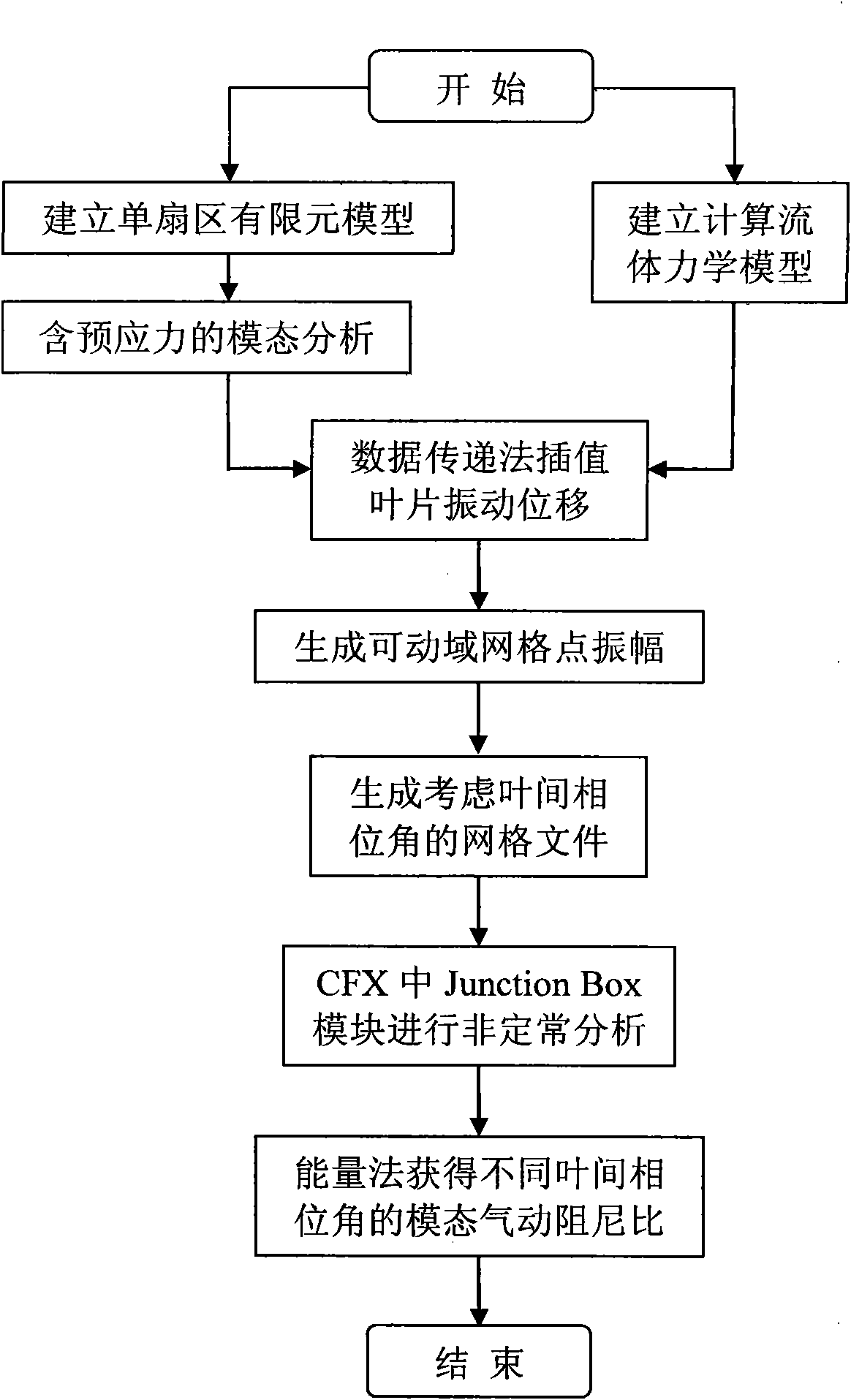

[0081] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The present invention is a method for predicting fluid-solid coupling of aeroelastic stability by considering the inter-blade phase angle of a turbomachinery. The flow of the method is as follows: figure 1 shown.

[0082] Step 1: Establish a single-sector finite element model;

[0083] A single-sector finite element model of the turbomachinery is established in the finite element software MARC for a given solid model;

[0084] Step 2: Perform modal analysis with prestress on the established finite element model;

[0085] First, the finite element model established in MARC is imported into the finite element software ANSYS, the corresponding material parameters are defined, and the rotational speed and displacement constraints are given, and the prestress caused by centrifugal force is obtained through static analysis;

[0086] Then, the modal analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com