Material analysis and prediction system

A forecasting system and material technology, applied in the field of management system, can solve the problems of inaccurate material planning, inaccurate production capacity analysis, production disorder, etc., to achieve the effect of controlling negligence and omission, fast analysis function, reasonable and intelligent adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

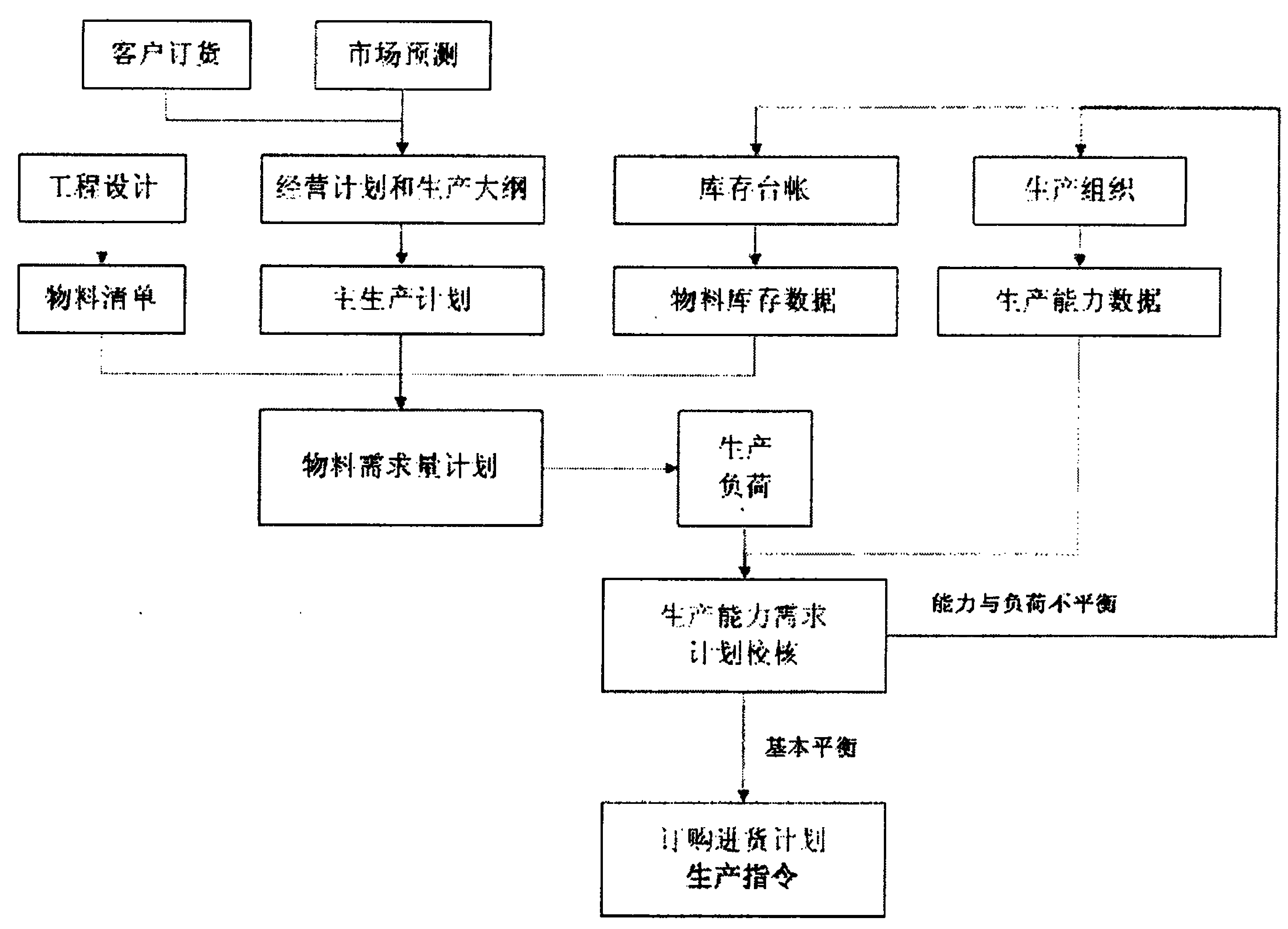

[0024] like figure 1 As shown, a material analysis forecast management system of the present invention is characterized in that it includes:

[0025] Basic information management platform

[0026] As a public part of the entire system, it provides basic services for the entire system. Including basic information maintenance, dictionary data maintenance.

[0027] Management and maintenance platform

[0028] Used by system administrators. Including parameter configuration, process management, data backup and system log and other four parts.

[0029] User management platform

[0030] The basis for ensuring the safe operation of the software, completes the flexible configuration function, and does not need to modify the code to achieve user security, role division, and verification to the minimum authority of each button. The realization of the second upgrade development zero code. The main functions include system login, user management, role management, function managemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com