Fuel cell, method of manufacturing same, electronic device, immobilized-enzyme electrode, method of manufacturing same, water repellent agent, and enzyme immobilization material

A fuel cell and manufacturing method technology, applied in fuel cells, battery electrodes, biochemical fuel cells, etc., can solve problems such as resource consumption, fuel cell heating, and electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The embodiments of the present invention will be described below with reference to the drawings.

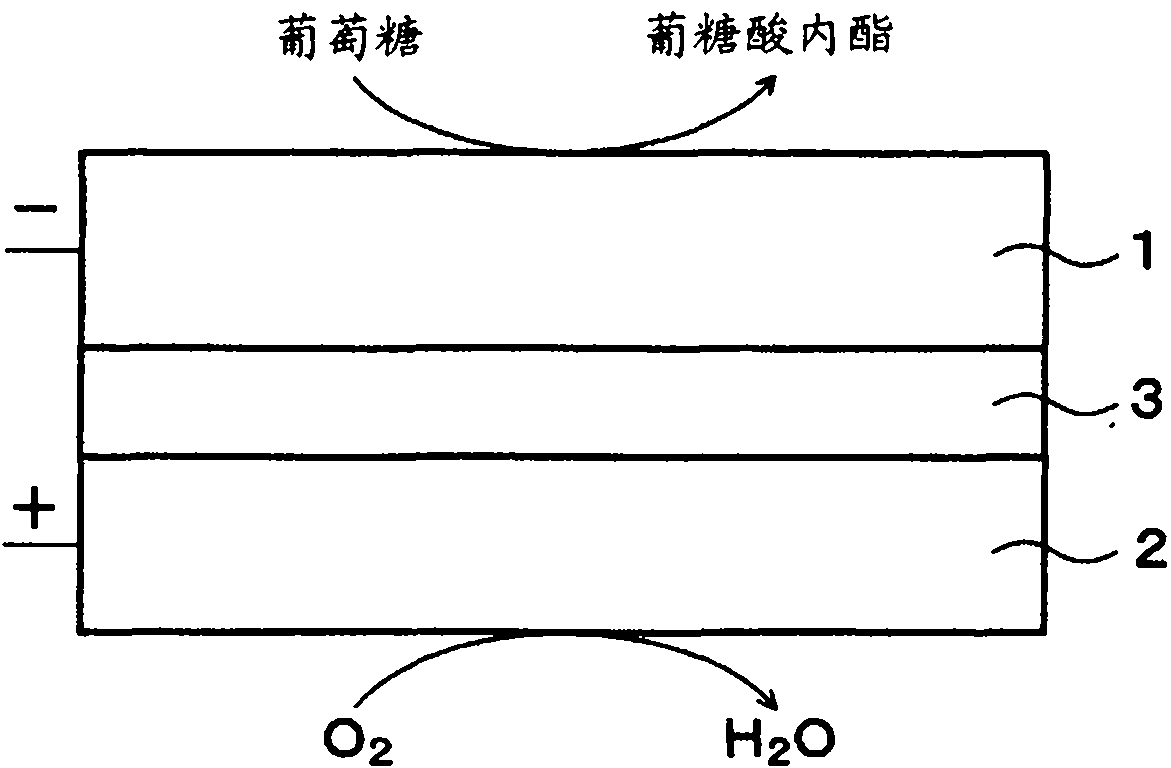

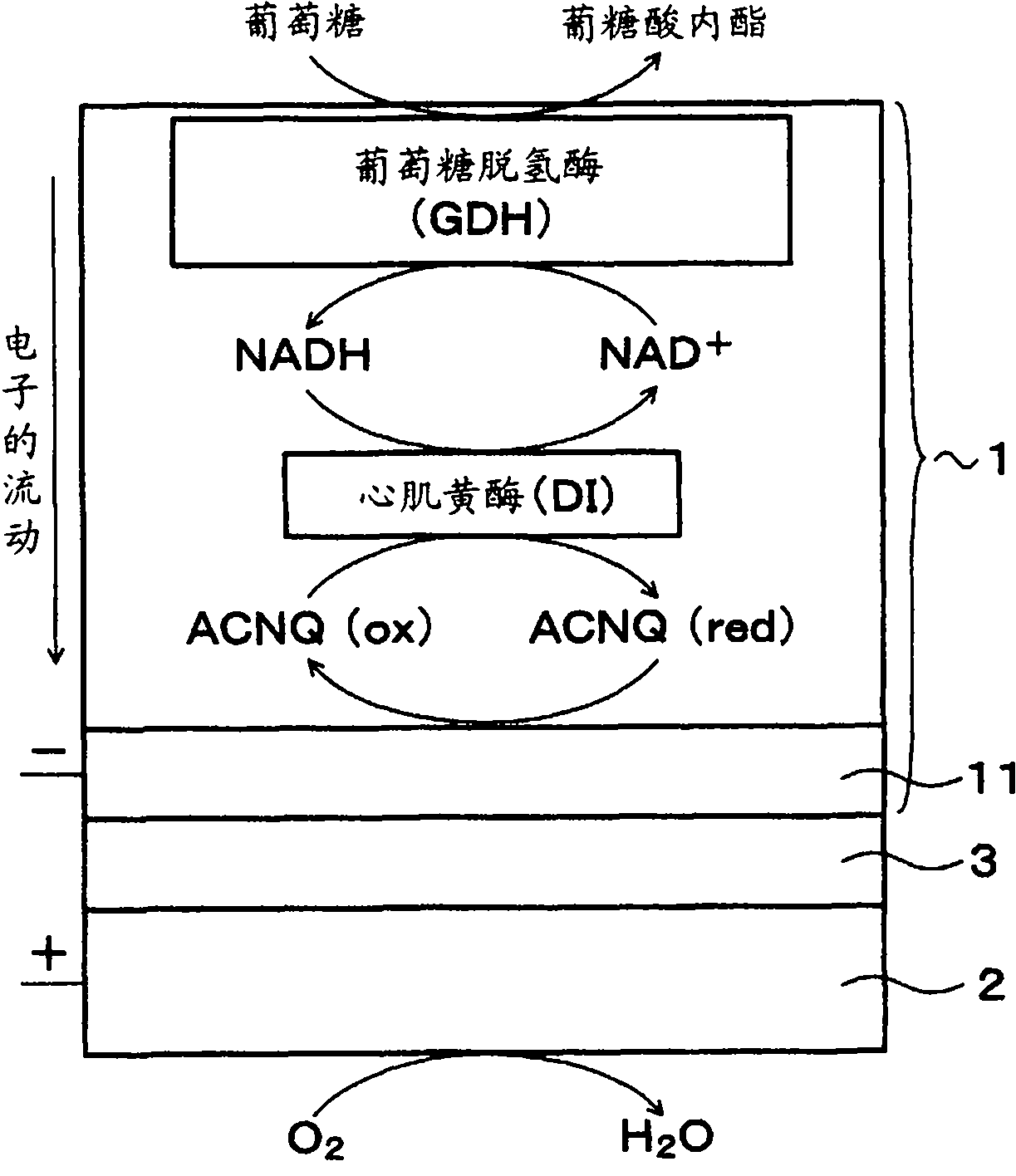

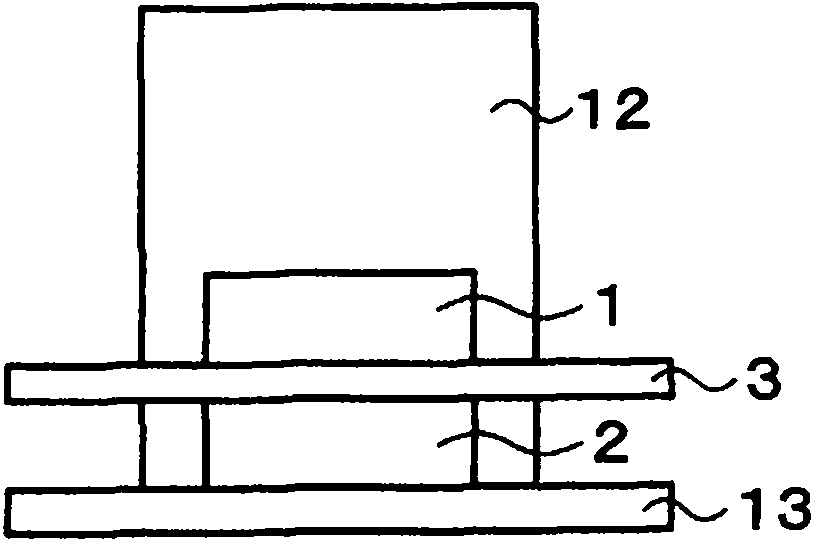

[0090] figure 1 The biofuel cell according to the first embodiment of the present invention is schematically shown. Assume that glucose is used as the fuel in the biofuel cell. figure 2 The details of the negative electrode structure of the biofuel cell, an example of the group of enzymes (enzyme group) immobilized on the negative electrode, and the reaction of electron reception / transmission by the enzyme group are schematically shown.

[0091] Such as figure 1 As shown, the biofuel cell has a structure in which the negative electrode 1 and the positive electrode 2 face each other through an intermediate electrolyte layer 3 that only conducts protons. The negative electrode 1 decomposes glucose supplied as fuel by enzymes to extract electrons and generate protons (H + ). The positive electrode 2 generates water by protons transferred from the negative electrode 1 via the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com