Automatically-aligned numerical control cutting method for pre-printed image plate

A cutting method and technology for printing images, applied in automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of low processing accuracy and low precision, and achieve low hardware cost, high-precision cutting processing, alignment high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

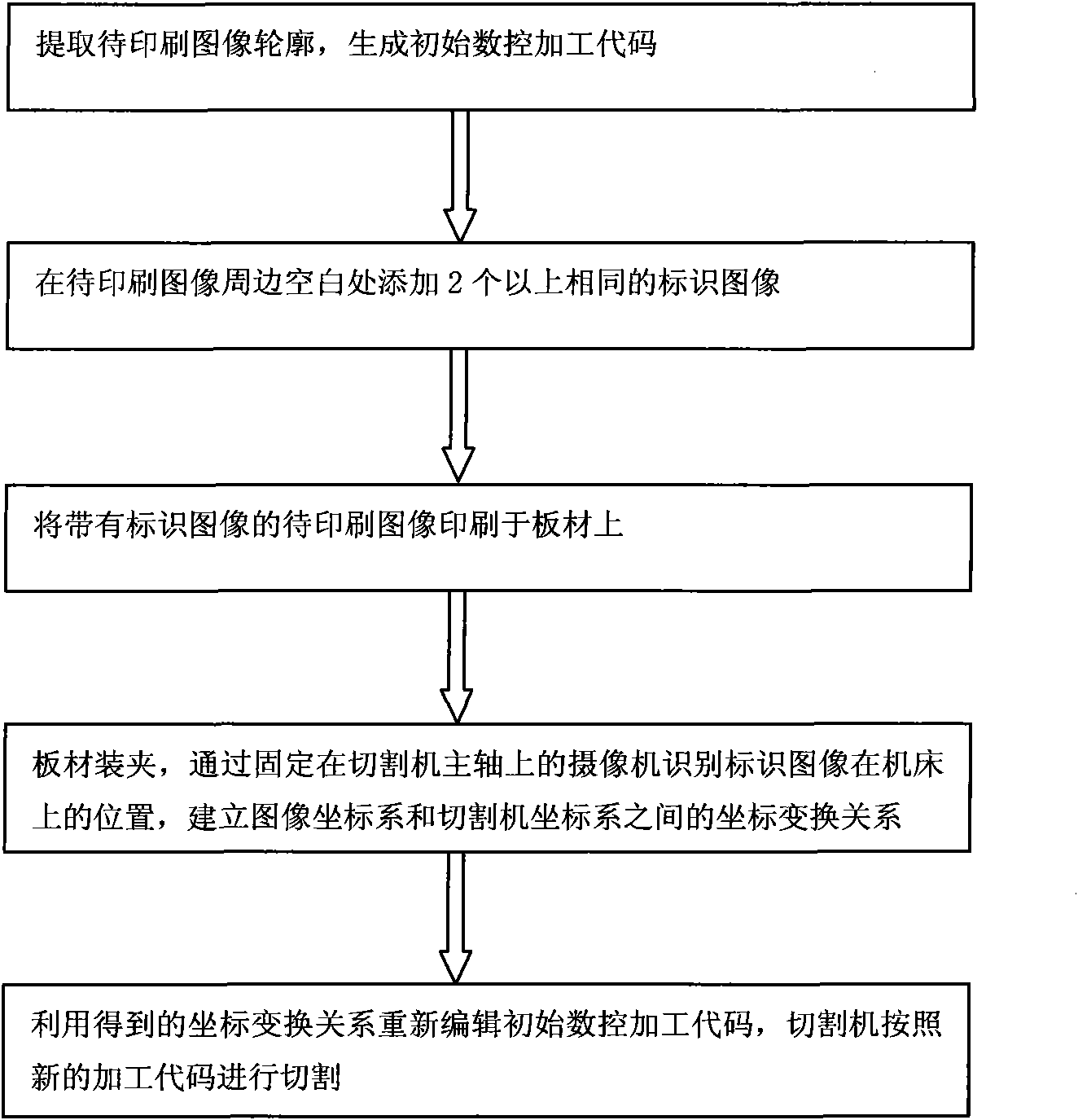

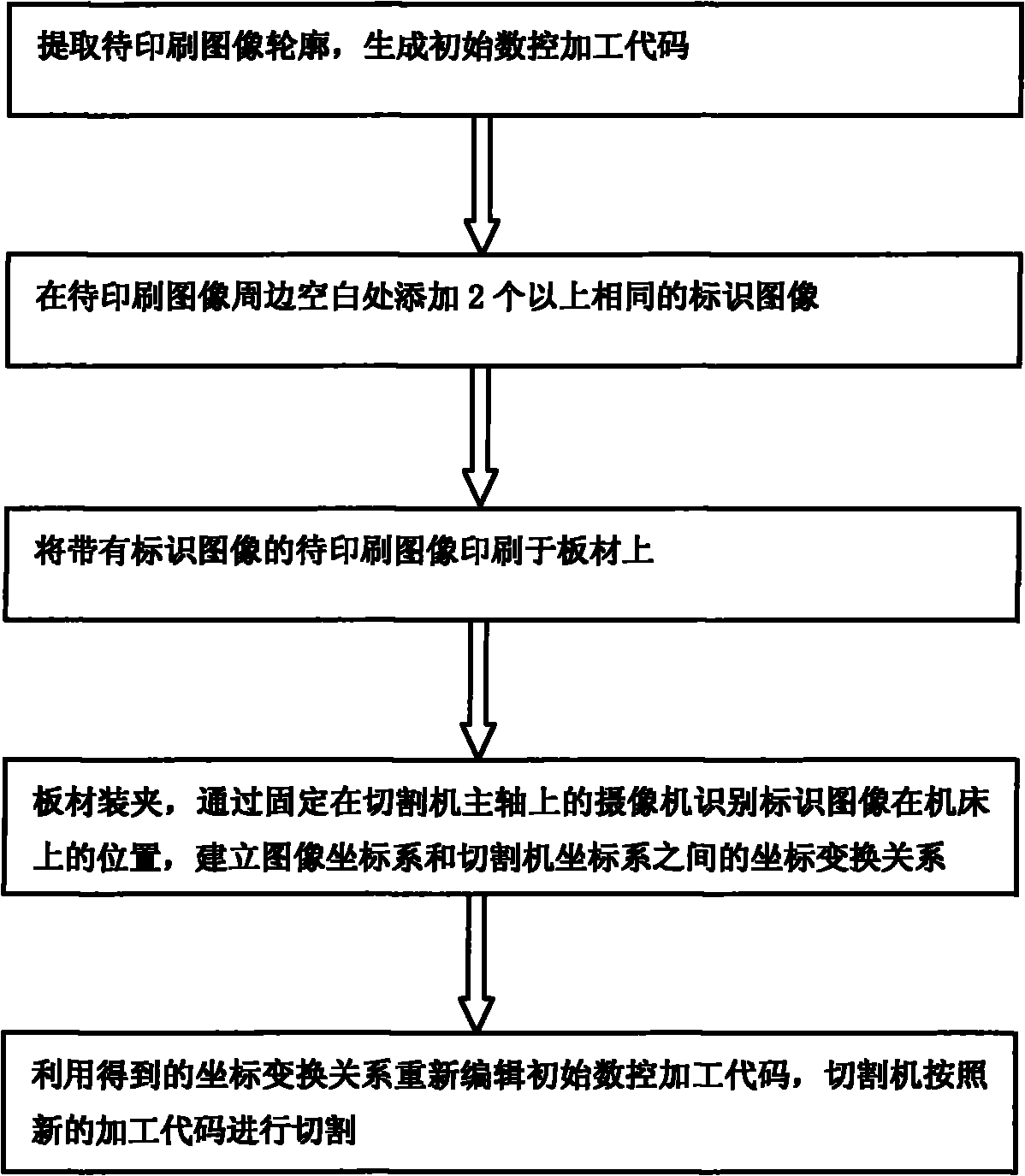

[0030] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0031] as attached figure 1 As shown, the present invention realizes the alignment of pre-printed image plate CNC cutting through the following steps:

[0032] A. Extract the outline of the image to be printed and generate the initial CNC machining code according to the extracted image outline; it is specifically divided into the following steps:

[0033] A1. Carry out binarization processing to the image to obtain a preliminary graphic outline;

[0034] In this embodiment, according to the image grayscale, the method of maximum variance between classes is used to perform image binarization processing, and the Otsu method is used to select the binarization threshold;

[0035] Both the maximum inter-class variance method and the Otsu method in this step are existing technologies in the field of image processing. For details, please refer to the literat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Inner circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com