Nitrogen supercharging vehicle

A nitrogen, vehicle owner technology, applied in motor vehicles, goods transport vehicles, vehicles used for freight, etc., can solve problems such as difficulty in moving equipment, affecting work efficiency, inconvenient operation and use, etc., to improve heat dissipation, and facilitate operation and maintenance. , easy to use and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

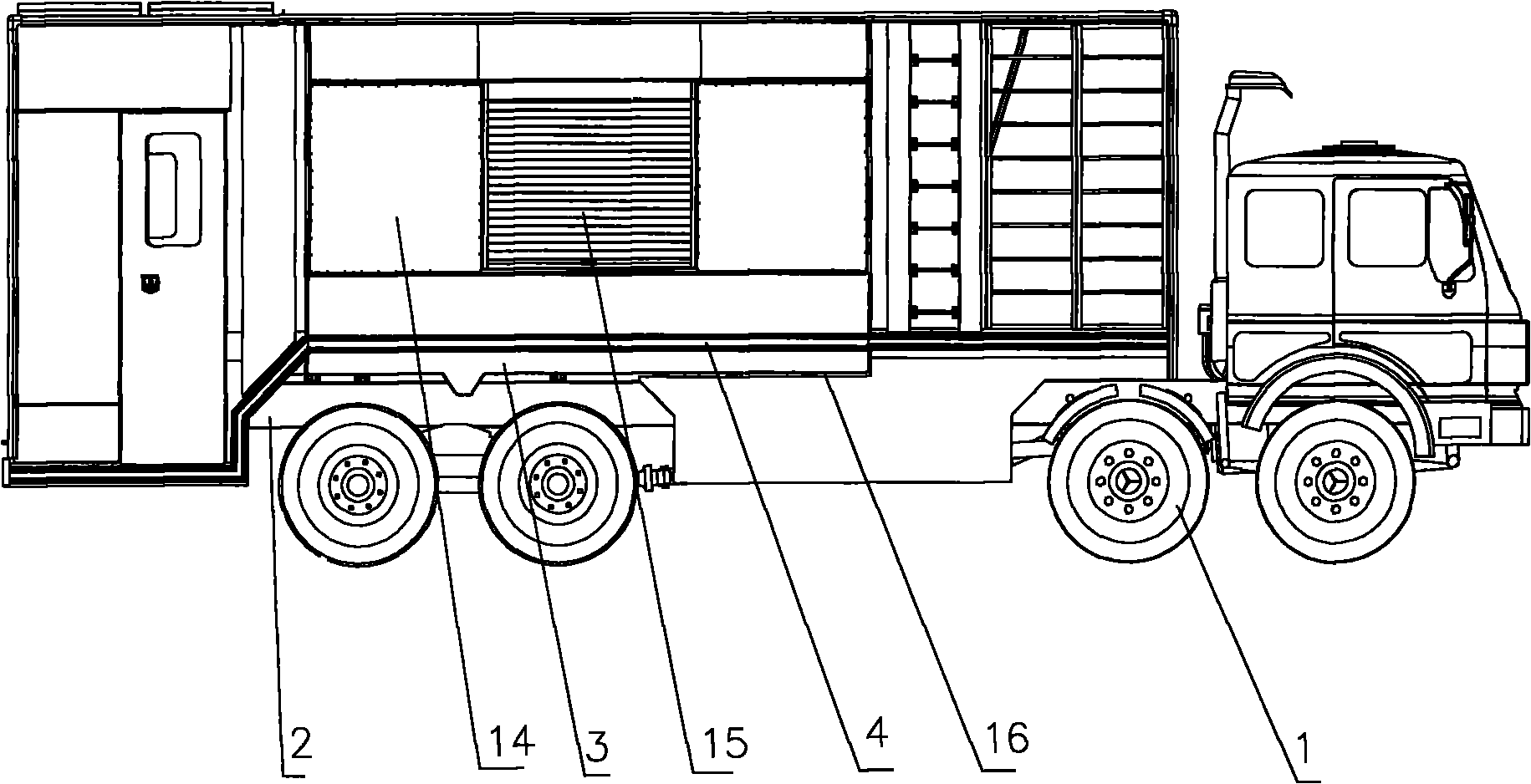

[0035] combine figure 1 , design and manufacture the top-loading skid box 4 that meets the standard according to the national standard automobile outline size limit, and this top-loading skid box 4 is connected with the second-class automobile chassis 1 to form a special operation vehicle. In the connection relationship between the sub-frame 3 of the chassis and the skid box 3 of the upper body, research and invention have been made to connect and fix the angle-shaped connecting plate that meets the requirements of material mechanics and engineering mechanics. While limiting the longitudinal displacement between the upper skid and the sub-frame, the lateral displacement is also limited. The chassis main beam 2 and the chassis sub-frame 3 are connected by U bolts. In order to improve safety, the axial direction of U-bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com