Novel steel wire core conveyer belt detector for mine

A steel wire rope core and detection device technology, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as reduced detection data accuracy, distortion of perspective image stretching or compression, and affecting the accuracy of collected images, etc. , to achieve the effects of stable ray output, improved velocity measurement accuracy, and low leakage dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

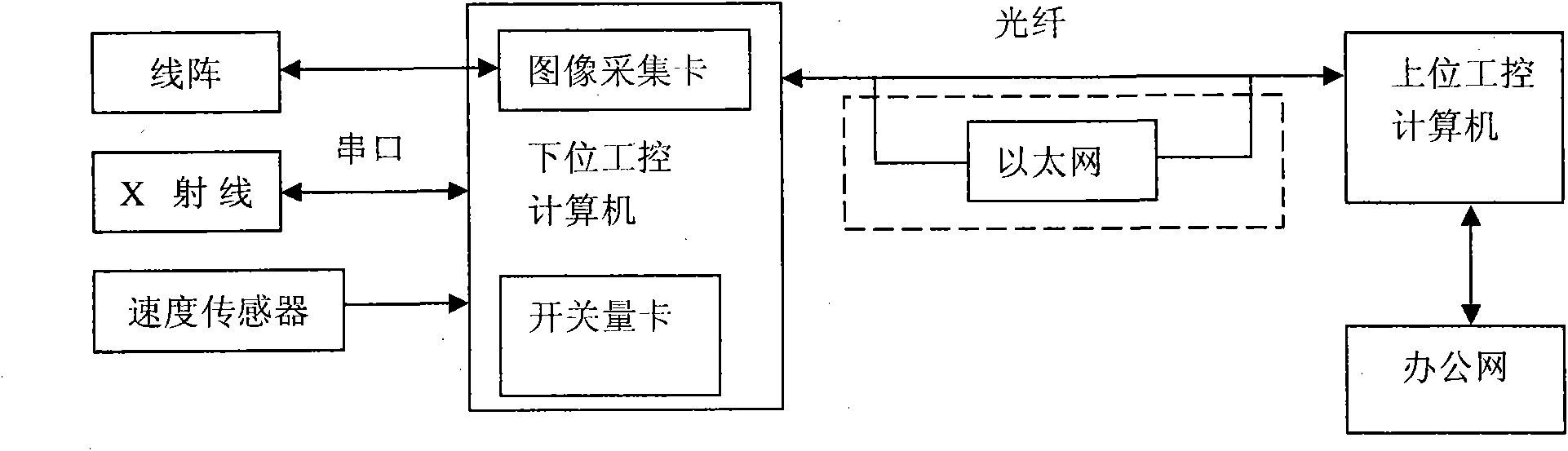

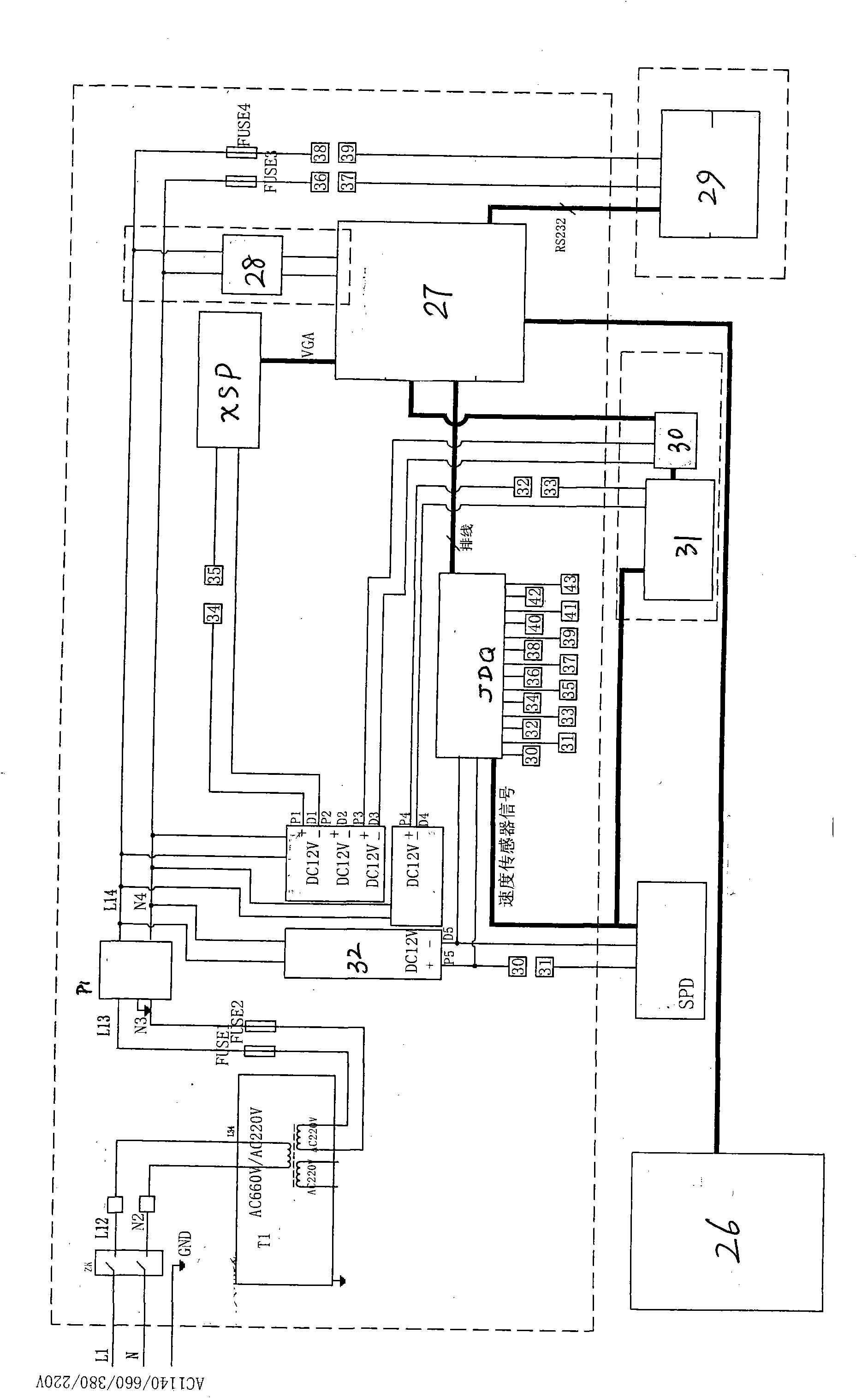

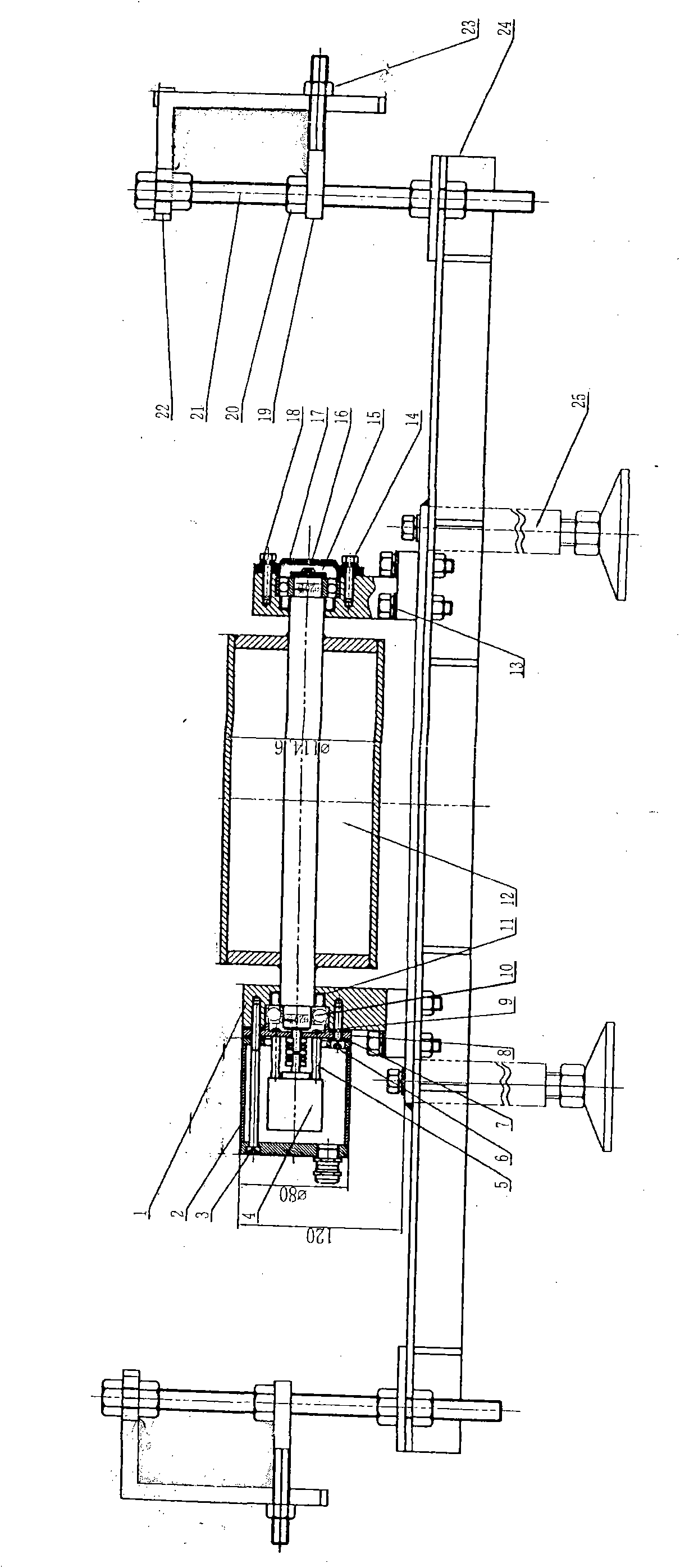

[0037] Example: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, this embodiment includes a line array receiver, an X-ray source, a speed sensor, a lower-level industrial control computer, and an upper-level industrial control computer. The X-ray source and the speed sensor are connected to the lower-level industrial control computer, and the line array receiver is connected to the lower-level industrial control computer through a fiber optic converter. The image acquisition card of the lower industrial control computer is connected to the relay board through the cable, the relay board is connected to and controls the power supply line of the line array receiver, X-ray source, and speed sensor, and the lower industrial control computer is connected to the upper industrial control computer.

[0038] figure 2 As shown, the output of the speed sensor is connected to the lower industrial control computer, the output of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com