Connection method of reactive sintered silicon carbide ceramics

A technology for sintering silicon carbide and silicon carbide ceramics, which is applied in the field of bonding and connecting ceramic parts, can solve the problems of poor high temperature resistance and affect the stability of ceramic welding parts, and achieves the goal of reducing the difficulty of production, reducing the scope of damage and improving the yield of products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

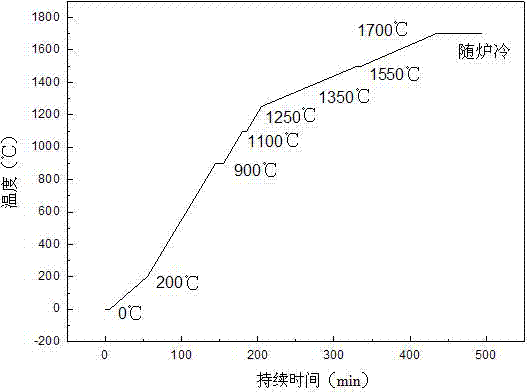

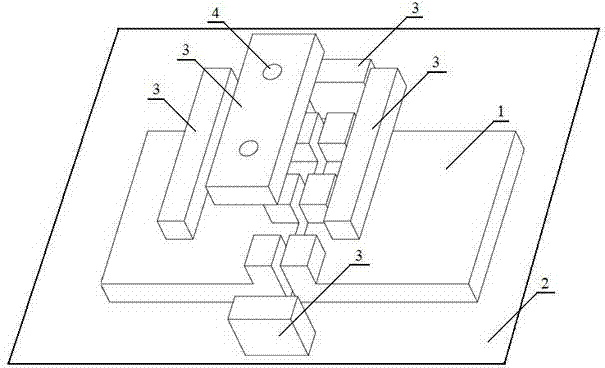

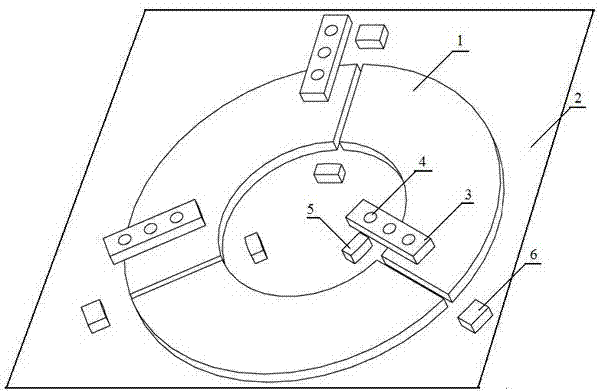

[0017] Specific implementation mode one: (in combination figure 2 - 5 for explanation) The connection method of the reaction sintered silicon carbide ceramic parts in this embodiment is as follows: 1. Place the split silicon carbide ceramic parts to be connected horizontally on the graphite plate, and separate the silicon carbide ceramic parts with the graphite plate Fill the gap between them with plasticine, and the distance between the split surfaces of the silicon carbide ceramic parts is 5mm; 2. Use gypsum board to surround the space formed by the surfaces to be connected of the silicon carbide ceramic parts to form a cavity, covering the The gypsum board on the split surface of the silicon carbide ceramic part to be connected has a pouring hole, and then the slurry used to prepare the silicon carbide ceramic is filled through the pouring hole on the gypsum board to fill the cavity between the split surfaces of the silicon carbide ceramic part, Then dry at room temperatur...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the drying temperature in step 2 is 38°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the drying temperature in step 2 is 35°C. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com